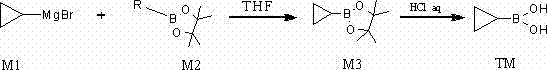

Method for preparing cyclopropylboric acid

A technology of cyclopropyl boronic acid and cyclopropyl bromide, applied in the field of preparing cyclopropyl boronic acid, can solve problems such as potential safety hazards and danger, and achieve the effects of low risk, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of method for preparing cyclopropyl boronic acid, boronation is with isopropoxy borate pinacol ester, and hydrolysis oxidant is example with potassium permanganate:

[0023] The preparation of the first step raw material cyclopropylmagnesium bromide:

[0024] Under nitrogen protection, add 9.16 g (0.382 mol) of magnesium, 340 mL of tetrahydrofuran, and 2.0 g of cyclopropyl bromide (0.016 mol) into a 500 ml four-necked flask equipped with a mechanical stirrer, a thermometer, and a condenser. Raise the temperature to 50°C and keep warm to initiate the reaction. After the start, control the temperature of the kettle at 40-60°C and add 40g cyclopropyl bromide (0.331mol) dropwise. After the dropwise addition, keep warm for 2 hours and analyze the concentration of Grignard reagent cyclopropylmagnesium bromide. 0.95mol / kg, 347.0g, yield 95%.

[0025] The preparation of the second step cyclopropyl boronic acid:

[0026] Add 67.46g (0.363mol) isopropoxy pinacol borate a...

Embodiment 2

[0028] A kind of method for preparing cyclopropyl boronic acid, boronation is with isopropoxy boric acid pinacol ester, and hydrolysis oxidant is example with potassium periodate:

[0029] The preparation of the first step raw material cyclopropylmagnesium bromide:

[0030] Same as the first step of embodiment 1:

[0031] The preparation of the second step cyclopropyl boronic acid:

[0032] Add 67.46g (0.363mol) isopropoxy pinacol borate and 150ml (1.85mol) tetrahydrofuran to a 1L four-neck flask equipped with a mechanical stirrer, a thermometer, and a condenser tube under nitrogen protection, and add the first Bug Grignard reagent 347.0g (0.330mol), keep warm for 1 to 5 hours after dropping, monitor the gas phase after the reaction is completed, control the room temperature and drop 10% hydrochloric acid aqueous solution to adjust the pH value of the kettle liquid to 1 to 3, and then add potassium periodate 6.84g (0.032mol) was stirred for 2-10 hours, and the reaction was c...

Embodiment 3

[0034] A kind of method for preparing cyclopropyl boronic acid, boronation is with isopropoxy boric acid pinacol ester, and hydrolysis oxidant is example with cerium ammonium nitrate:

[0035] The preparation of the first step raw material cyclopropylmagnesium bromide:

[0036] Same as the first step of embodiment 1:

[0037] The preparation of the second step cyclopropyl boronic acid:

[0038] Add 67.46g (0.363mol) isopropoxy pinacol borate and 150ml (1.85mol) tetrahydrofuran to a 1L four-neck flask equipped with a mechanical stirrer, a thermometer, and a condenser tube under nitrogen protection, and add the first Bug Grignard reagent 347.0g (0.330mol), keep the temperature for 1 to 5 hours after the dropping, gas phase monitoring after the reaction is completed, control the room temperature and drop 10% hydrochloric acid aqueous solution to adjust the pH value of the kettle liquid to 1 to 3, and then add cerium ammonium nitrate 17.54 g (0.032mol) was stirred for 2-10 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com