Air pipe component of shot blasting machine

A shot blasting machine and air duct technology, which is applied in the direction of grinding/polishing equipment, used abrasive processing devices, abrasives, etc., can solve the problems of sinking, large wind resistance of the pill collector, poor dust removal effect, etc., and achieve reduction The effect of height, convenient transportation and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

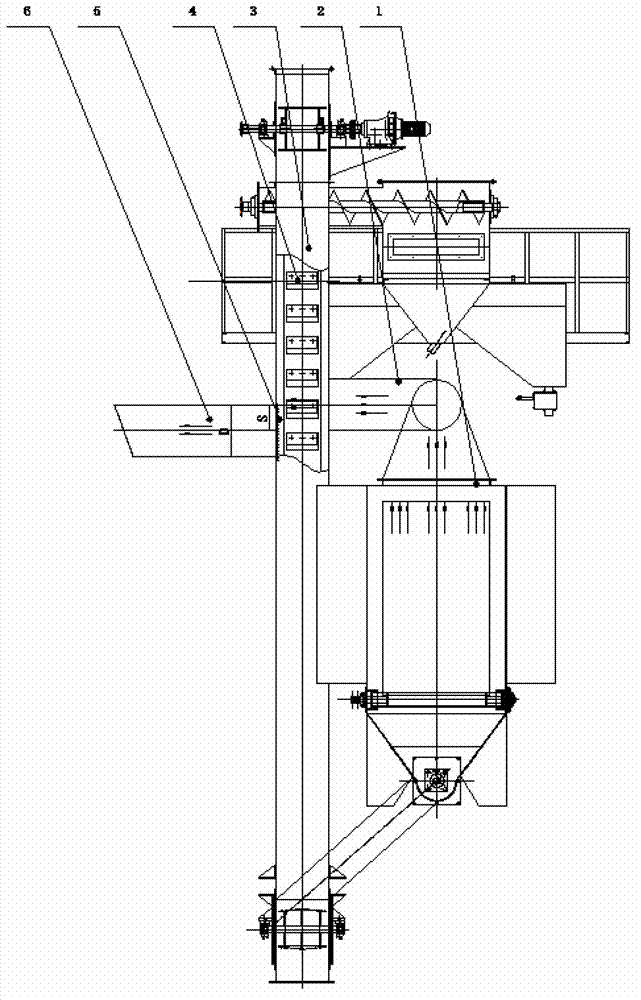

[0011] Shot blasting machine air duct assembly, which includes air duct I2, air duct II6, hoist 3 and shutter 5. The air intake end of the air duct I2 is connected to the air intake 1, and the air outlet opening is arranged on the side of the lifting tube of the hoist 3. On the lifting cylinder, on the side opposite to the opening of the air outlet of the air pipe I2, there is an opening of the air inlet of the air pipe II6, and the air outlet of the air pipe II6 is connected to the dust collector. The opening of the air inlet end of the air duct II6 is lower than the opening of the air outlet end of the air duct I2, and the opening of the air inlet end of the air duct II6 is equipped with a louver 5 . Assuming that the height difference between the opening of the inlet end of the air duct II6 and the opening of the air outlet end of the air duct I2 is S, and the diameter of the air duct is D, then D / 2≤S≤D / 3. When the high-speed airflow entraining the steel shot enters the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com