Preparation method of soybean peptide-calcium chelate

A technology of soybean peptide and calcium chelate, applied in the field of preparation of soybean peptide, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing soybean peptide-calcium chelate. In one embodiment, after the soybean meal is decomposed by solid-state fermentation with koji bacteria, a hydrolysis reaction is performed, and then a clarification step is performed to obtain a clarified hydrolysate, and then calcium chloride is directly added to the clarified soybean hydrolysate to mix, and Adjust the water content and pH to obtain a liquid containing soybean peptide-calcium chelate. In another embodiment, the clarified soybean hydrolysate can be subjected to a powdering step, and then the soybean peptide powder and calcium ions are mixed with water and stirred to dissolve, and the pH value is adjusted to prepare a soybean peptide-calcium chelate. The peptide product of the compound.

[0019] The present invention uses soybeans to produce soy peptides. The principle is to use Aspergillus oryzae, Aspergillus sojae or the Aspergillus sojae to process raw materials containing so...

Embodiment 1

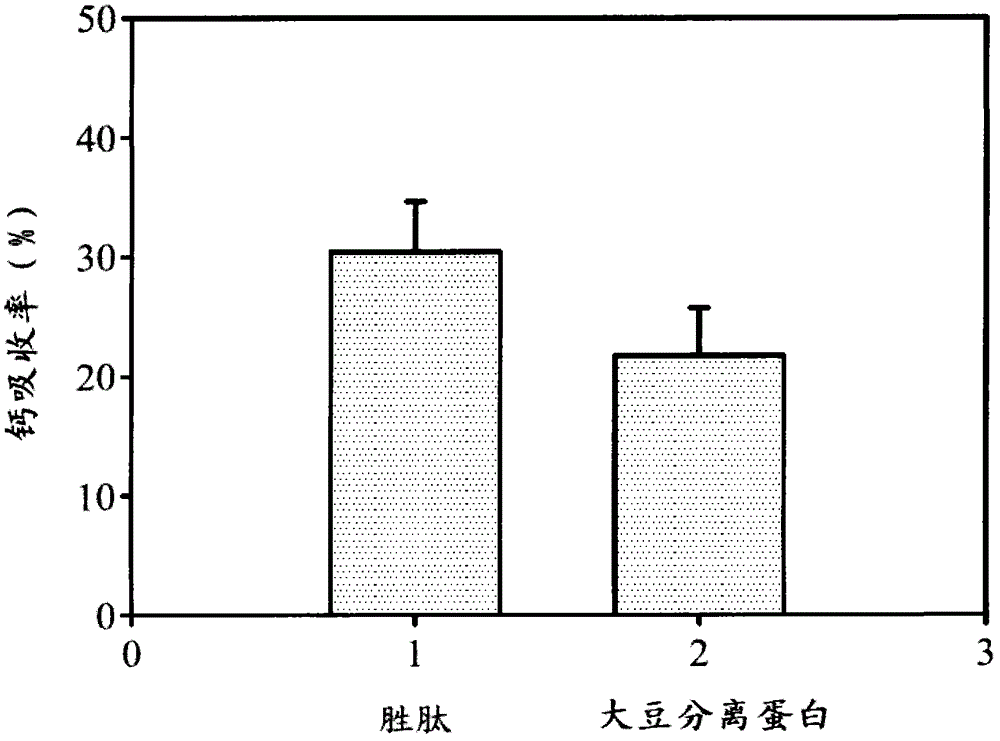

[0028] Example 1. Manufacture of soybean peptide to promote calcium absorption

[0029] Use defatted soybean meal as raw material to inoculate Aspergillus sojae, in which the amount of aspergillus inoculation is 0.013% of the total weight of the soybean raw material, and the weight percentage is 0.25% CH 3 COONa / 0.25%HNaSO 3 , PH=5.8 buffer solution to adjust the moisture to 55%, incubate for 2 days in an environment of 25-30°C and relative humidity above 95%.

[0030] Then proceed to the hydrolysis reaction and mix the soybean koji with water, where the ratio of soybean koji to water is 1:2, the hydrolysis time is 6 hours, the hydrolysis temperature is 45°C, and the temperature is increased to 90-95°C and maintained for 10 minutes to suppress Enzyme activity.

[0031] Next, the clarification treatment of the hydrolysate is performed. First, a squeezer is used to place the soybean hydrolysate in a filter bag, spread it flat in the squeeze tank, and separate the solid and liquid by hy...

Embodiment 2

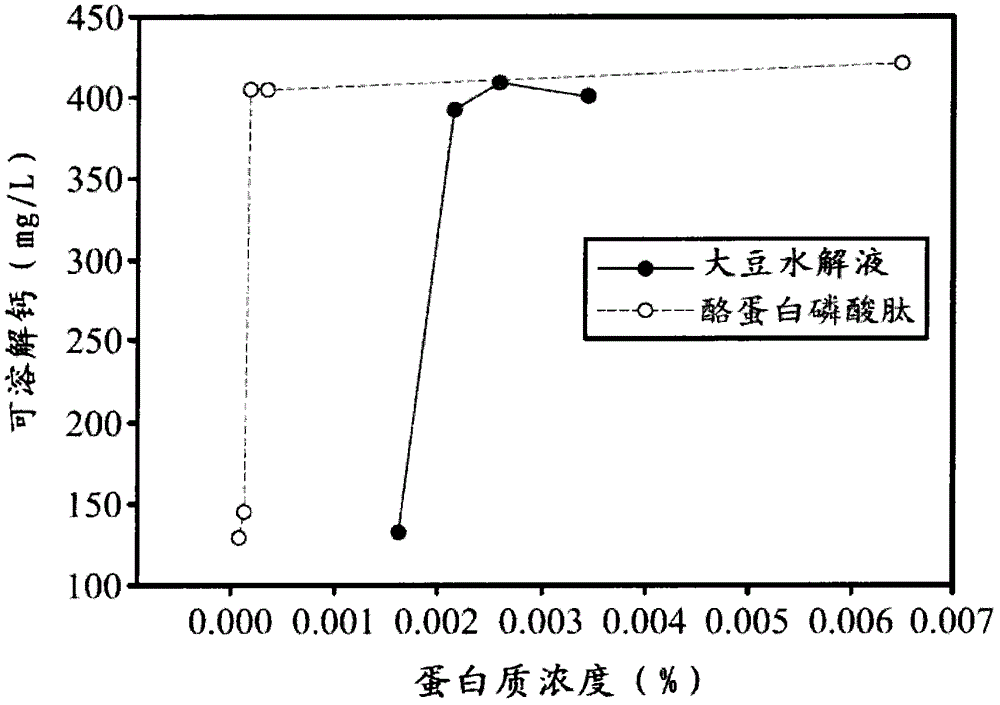

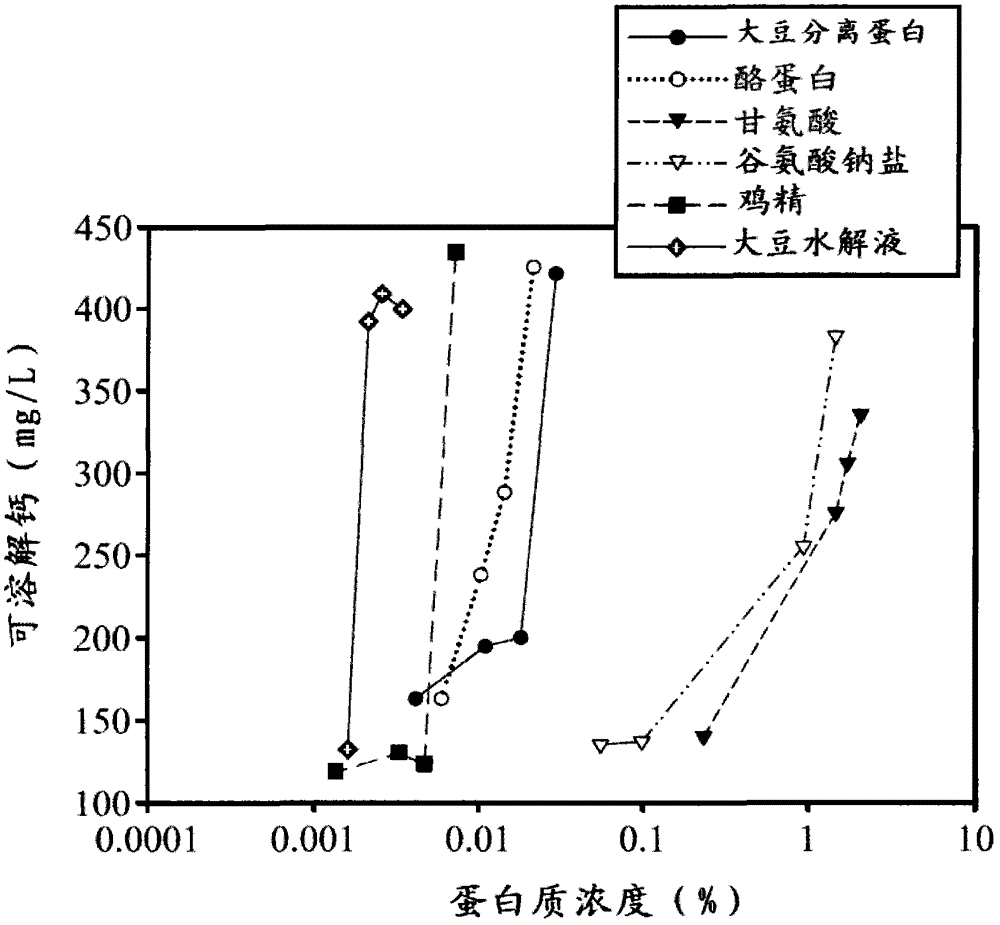

[0032] Example 2. The effect of soybean hydrolyzate on inhibiting calcium carbonate precipitation

[0033] According to Jin et al. (J.Agnc.Food Chem.2000) calcium carbonate crystallization experiment, slightly modified, 1mL sample was mixed with 1mL 40mM calcium chloride and 1.2mL distilled water, and then 0.8mL 40mM sodium bicarbonate was added to react. 1 hour, and use 0.1N sodium hydroxide titration to maintain pH=8.5. The reaction mixture was centrifuged (centrifugal force is 2000g), the supernatant was taken and the calcium concentration was measured using a calcium measuring reagent set (product of Merck, Taiwan), which is the soluble calcium content.

[0034] In the calcium carbonate crystallization inhibition experiment, the soy protein hydrolyzate obtained in Example 1 has an inhibitory effect on calcium carbonate crystallization. The evaluation of this effect is the lowest sample concentration that completely inhibits calcium carbonate crystallization under alkaline condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com