Method for producing dried turnip

A technology of dried radish and radish, applied in the field of preparation of dried radish, can solve the problems of single taste, poor flavor, long preparation time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

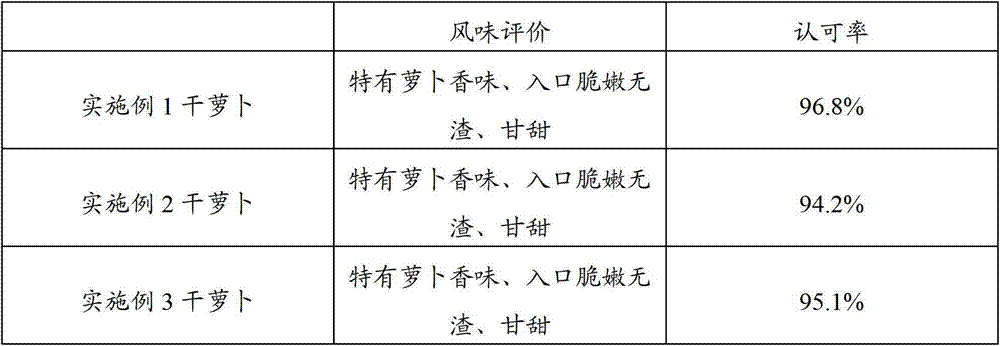

Embodiment 1

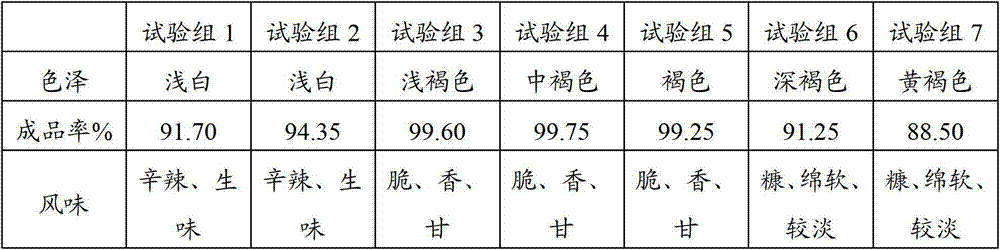

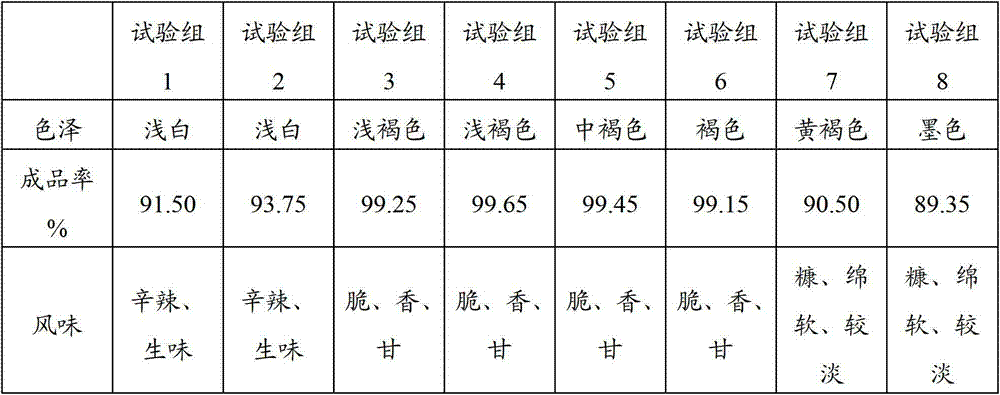

[0020] Embodiment 1: the method for preparing dried radish according to the present invention

[0021] After washing the fresh radish, pretreat it with medium-wave infrared at 120°C for 6 minutes;

[0022] Dry the pretreated radish with medium-wave infrared at 130°C for 20 minutes for initial color fixation, then dry with medium-wave infrared at 125°C for 25 minutes for mid-term color fixation, and finally use medium-wave infrared at 105°C Dry under the oven for 28 minutes for final color fixation;

[0023] Arranging and shaping the fixed radish, and then drying at 63°C for 15 minutes to obtain a medium brown or brown dried radish.

Embodiment 2

[0024] Embodiment 2: the method for preparing dried radish according to the present invention

[0025] After washing the fresh radish, pretreat it with medium-wave infrared at 110°C for 10 minutes;

[0026] Dry the pretreated radish with medium-wave infrared at 120°C for 30 minutes for initial color fixation, then dry with medium-wave infrared at 115°C for 25 minutes for mid-term color fixation, and finally use medium-wave infrared at 100°C Dry under the oven for 33 minutes for final color fixation;

[0027] Arranging and shaping the radishes after color fixation, and then drying them at 65°C for 15 minutes to obtain medium-brown or brown dried radishes.

Embodiment 3

[0028] Embodiment 3: the method for preparing dried radish according to the present invention

[0029] After washing the fresh radish, pretreat it with medium-wave infrared at 115°C for 3 minutes;

[0030] Dry the pretreated radish with medium-wave infrared at 125°C for 15 minutes for initial color fixation, then dry with medium-wave infrared at 120°C for 19 minutes for mid-term color fixation, and finally use medium-wave infrared at 103°C Dry under the oven for 23 minutes for final color fixation;

[0031] Arranging and shaping the radishes after color fixation, and then drying them at 60°C for 15 minutes to obtain medium-brown or brown dried radishes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com