Device and method for separating skin and pulp of straw

The technology of a separation device and a separation method is applied in the field of separation device and axial flow drum, and can solve the problems of inability to use the harvester, occupying a large space, and large damage to the outer skin of the straw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

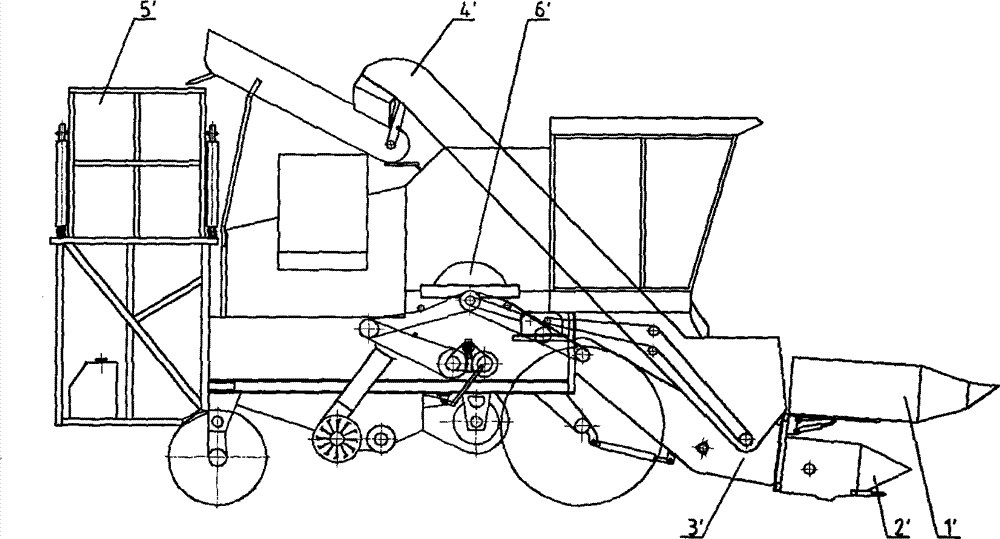

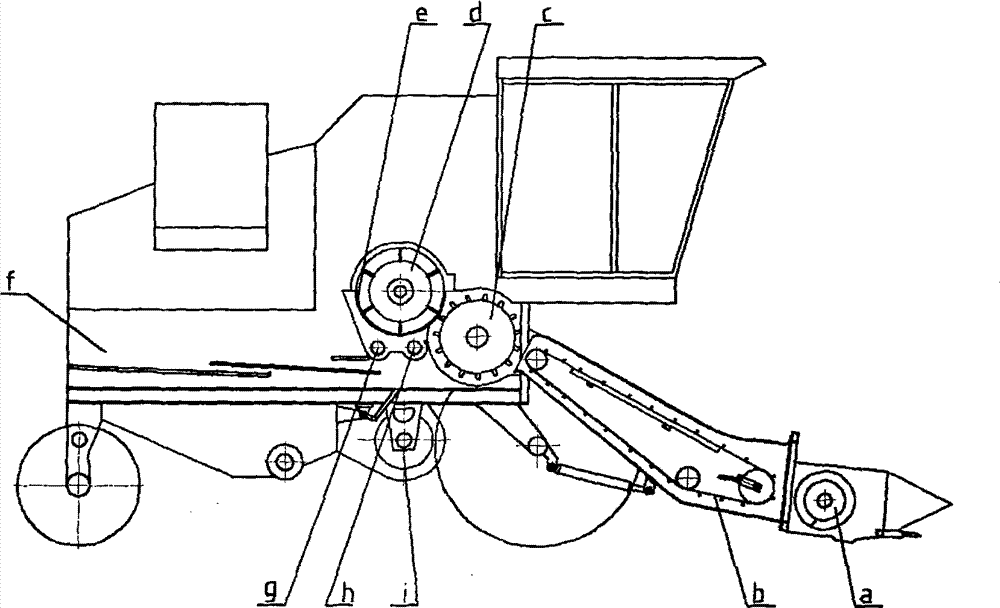

Embodiment 1

[0064] A corn stalk husk separation device includes an axial flow drum and a sieve. The sieve e is arranged below the drum d along the length of the axial flow drum d. There is a gap between the drum and the sieve, and the gap forms a straw separation space. Such as Figure 9 shown. The spiral deflector 17 on the harvester frame 11 and the inner surface of the sieve e form a roughly cylindrical tube concentric with the axial flow drum d, and a straw separation space is formed between the cylindrical tube and the outer surface of the axial flow drum d. The sieve is a semicircular grid-like frame structure, and the holes of the grid-like frame formed are long holes of 3cm×3.4cm, which are suitable for falling irregular lumpy crumbs and flake-like leaves. Such as Figure 6a with 6b shown. There is a gap of 5mm between the drum and the sieve. The axial-flow roller includes a supporting disc A1, a gear bar A2 and spikes A3. The gear bar A2 is a strip plate fixed on the outer c...

Embodiment 2

[0073] Others are the same as embodiment 1, the difference is:

[0074] The gear bar A2 is a long circular tube, and the gap between the drum and the sieve is 10mm.

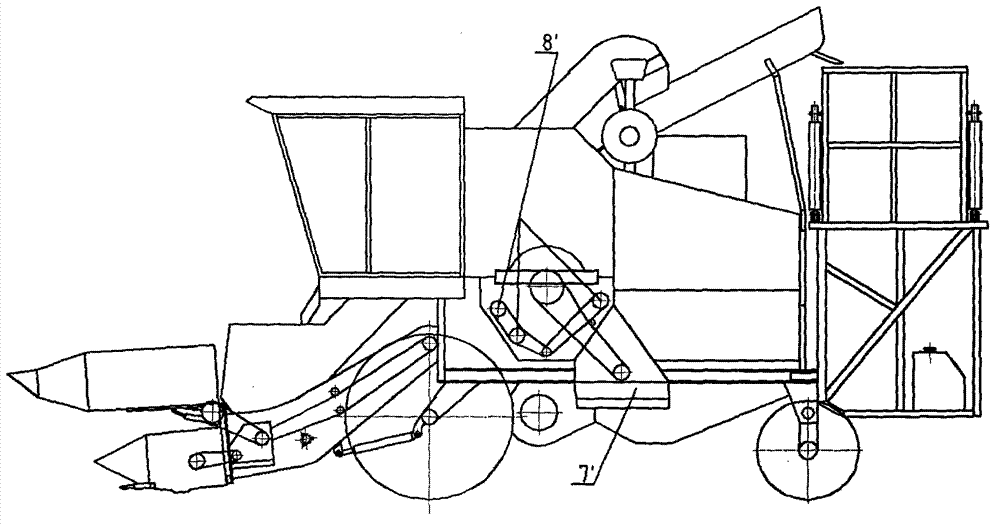

[0075] The corn stalk husk separation device also includes an anti-blocking device. The anti-blocking device is composed of a cleaning drum and a rotating shaft a1. The cleaning drum is composed of a sleeve a2 and round steel teeth a3 distributed on the circumference of the sleeve. The cleaning drum and the rotating The shaft is connected by set screw a4. Such as Figure 7 shown. The anti-blocking device is installed in the gap below the sieve. Such as figure 2 with Figure 8 shown.

[0076] If the leaves and husks of the straw are wet, the irregular lumpy husks and small pieces of leaves produced by the action of the drum and the sieve may adhere to the inner wall of the harvester after they leak through the sieve. The accumulation of sieve will block the sieve holes, resulting in weakened separation effe...

Embodiment 3

[0084] Others are the same as embodiment 1 or 2, the difference is:

[0085] There is a gap of 15mm between the drum and the sieve.

[0086] The corn stalk husk separation device also includes a straw husk dispersing device, which is installed at the exit of the harvester through bolt connection. The straw husk dispersing device is composed of a shell b1, a rotating shaft b3 and a breaking leaf b2, and the rotating shaft b3 and the dispersing blades b2 are installed in the casing b1; a sleeve is installed on the rotating shaft, and the dispersing blades are evenly distributed on the sleeve. Such as Figure 8 shown. The sleeve and the rotating shaft are connected by a key, and other connection methods are also available.

[0087] A method for separating corn stalk husks, comprising the following steps:

[0088] 1) The harvested corn stalks enter the drum;

[0089] 2) The drum rotates at a high speed, and the rotating speed of the drum is 900r / min. With the cooperation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com