Novel optical fiber type leakage detector used for direct-current converter valve

A DC converter valve and leak detector technology, which is applied in the application of light to test fluid tightness, etc., can solve the problem that the leak detector cannot identify the leakage flow, the valve tower cannot accurately monitor the water leakage, and the optical receiver has low identification power. and other problems, to achieve the effect of improving system reliability, low optical path attenuation rate, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

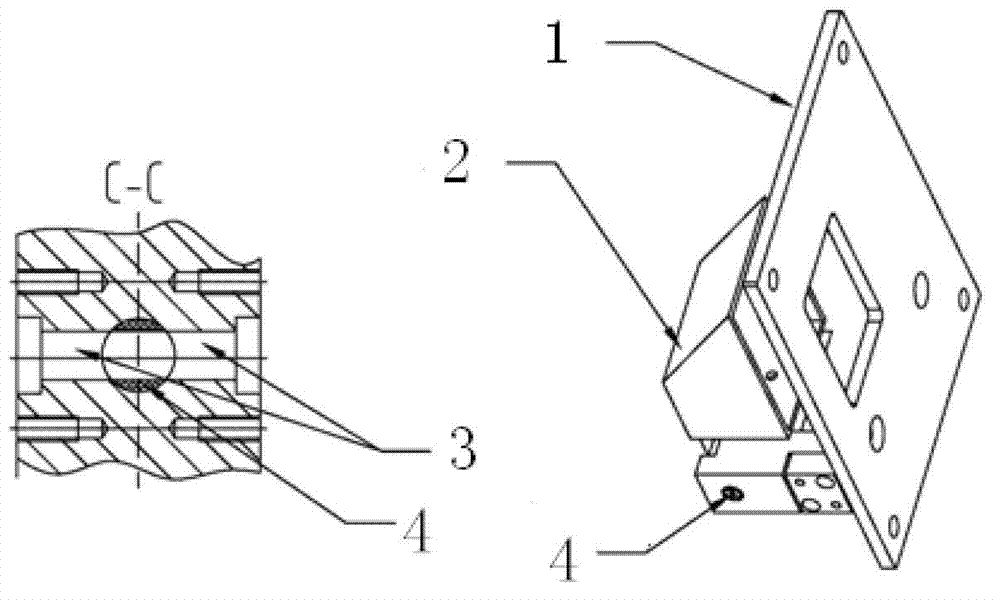

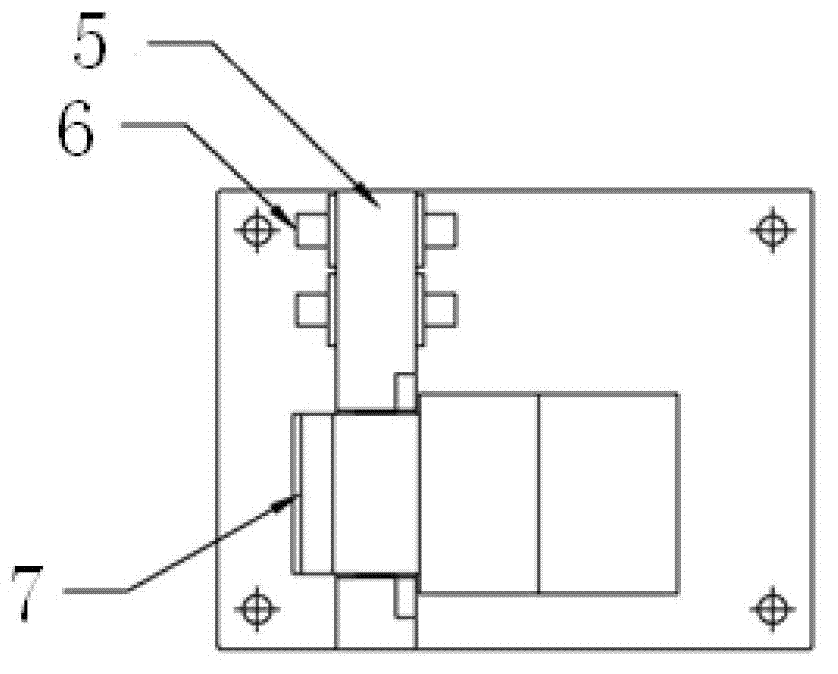

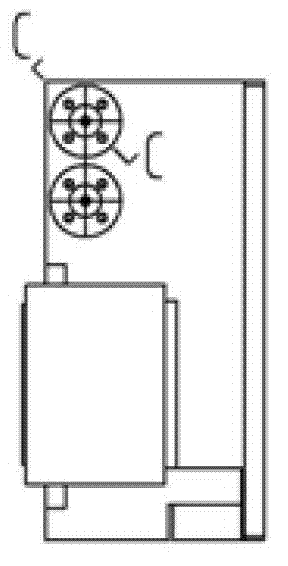

[0033] The invention provides an optical fiber leak detector for a direct current converter valve. The leak detector includes a liquid collector provided with a shielding metal plate at the bottom of the valve, a platform, a measuring piece and a leak detector; The collecting piece installed on the platform is connected with the leak detecting piece through an optical fiber; the collecting piece includes a bucket, a balance weight, a rotating shaft, and a collimating lens; the leak detecting piece includes a light emitting devices, photoreceivers, and valve-based electronics.

[0034] In this embodiment, the cooling liquid used by the converter valve is cooling water. see Figure 1-3 As shown, it shows the structural schematic diagram of the platform and the measuring piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com