Triangular area hydraulic support top protection device on upper end of large-inclination-angle working surface

A technology of hydraulic support and triangular area, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve problems such as hidden safety hazards of workers, support sliding, instability, etc., to solve support problems, ensure safety, prevent The effect of gangue falling and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

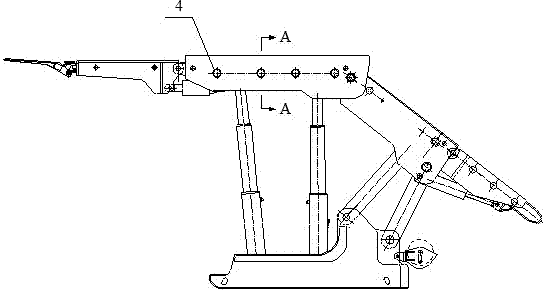

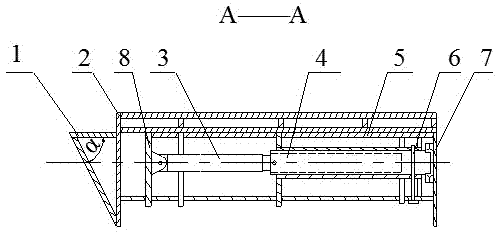

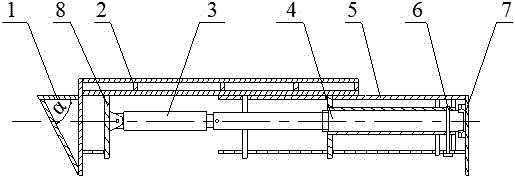

[0014] As shown in Fig. 1 and Fig. 2, the hydraulic support roof protection device in the triangular area at the end of the large-inclination working surface of the present invention mainly consists of the hydraulic support in the triangular area, the triangular box body 1, the movable side guard plate 2 of the top beam, and the double-acting side push jack 4. The beam body 5 and the side guard plate 7 are composed. The top beam of the triangular area hydraulic support includes the beam body 5, the top beam movable side guard plate 2 in a box-shaped structure arranged on the beam body 5, and the top beam movable side guard plate Sliding fit between the plate 2 and the beam body 5, the outer end of the beam body 5 is provided with a side guard plate 7, and the distance between the side guard plate 7 and the movable side guard plate 2 of the top beam is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com