Method for correcting unconformable surface stratum shield tunneling construction

A technology of shield tunneling and formation, which is applied in the field of deviation correction for shield excavation in unconformity ground, which can solve the problems of affecting normal traffic, long construction period, and difficult deviation correction, so as to improve the flexibility of deviation correction, reduce the pressure difference of deviation correction, and improve the flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

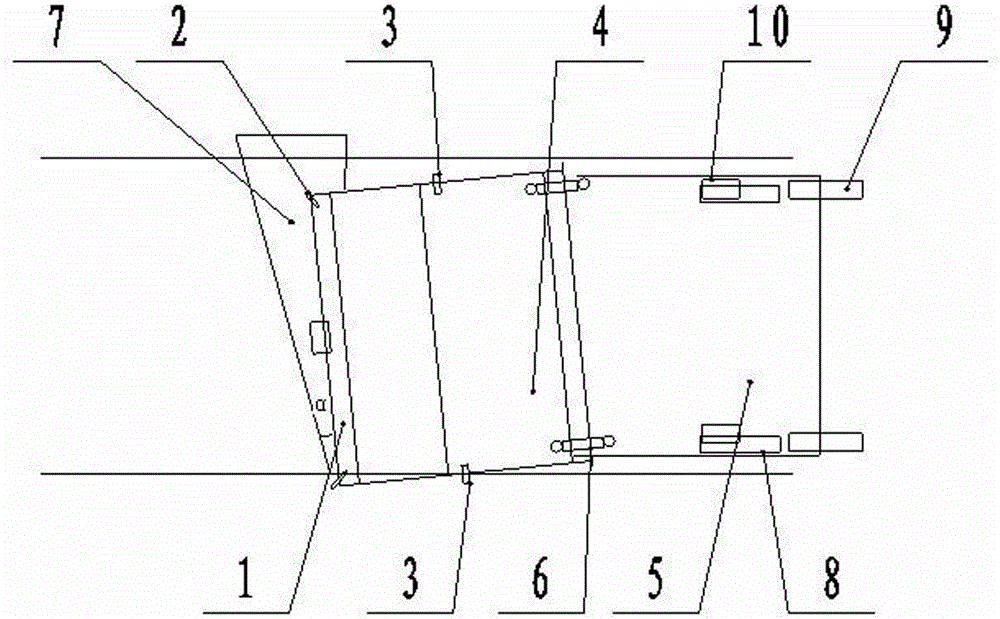

Image

Examples

example

[0034] There is a 50-meter rock stratum in the receiving section of Changsha Metro Line 1, Bid 10, from Zhongxin Plaza Station to Datuo Station, which is an unconformity stratum. When the shield tunneling on the left line is excavated, the posture is offset along the slope, and the trend of offset is becoming more and more serious by conventional methods. . The deviation trend was reduced after replacing the peripheral excavation knife, but the deviation could not be corrected. The continuous injection of high-pressure water with dispersant in the radial grouting hole of the shield body on the side of the shield body deviation can realize the containment of the shield body posture, but the deviation cannot be reduced. The deviation correction of the shield machine reduces the situation that the shield machine is shut down and changed to the mining method, and realizes the continuous tunneling of the shield machine to complete the construction task of the interval. It proves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com