Modular keel for building modular clean operating room

An operating room and modular technology, applied in the field of modular keels, can solve the problems that the overall quality level is difficult to be guaranteed, and achieve the effect of reducing the impact of human factors on product quality, reducing the impact of product quality, and facilitating upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

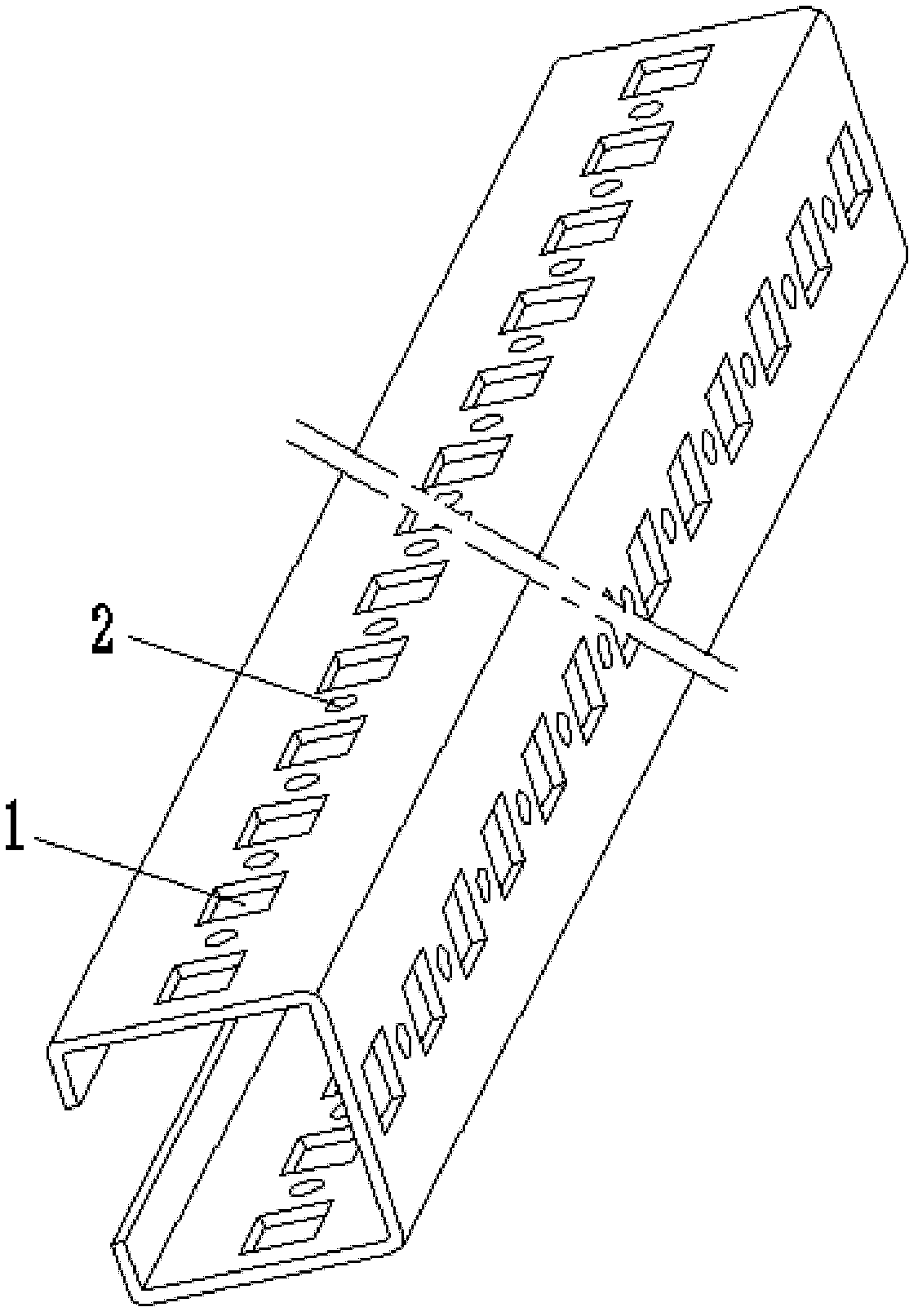

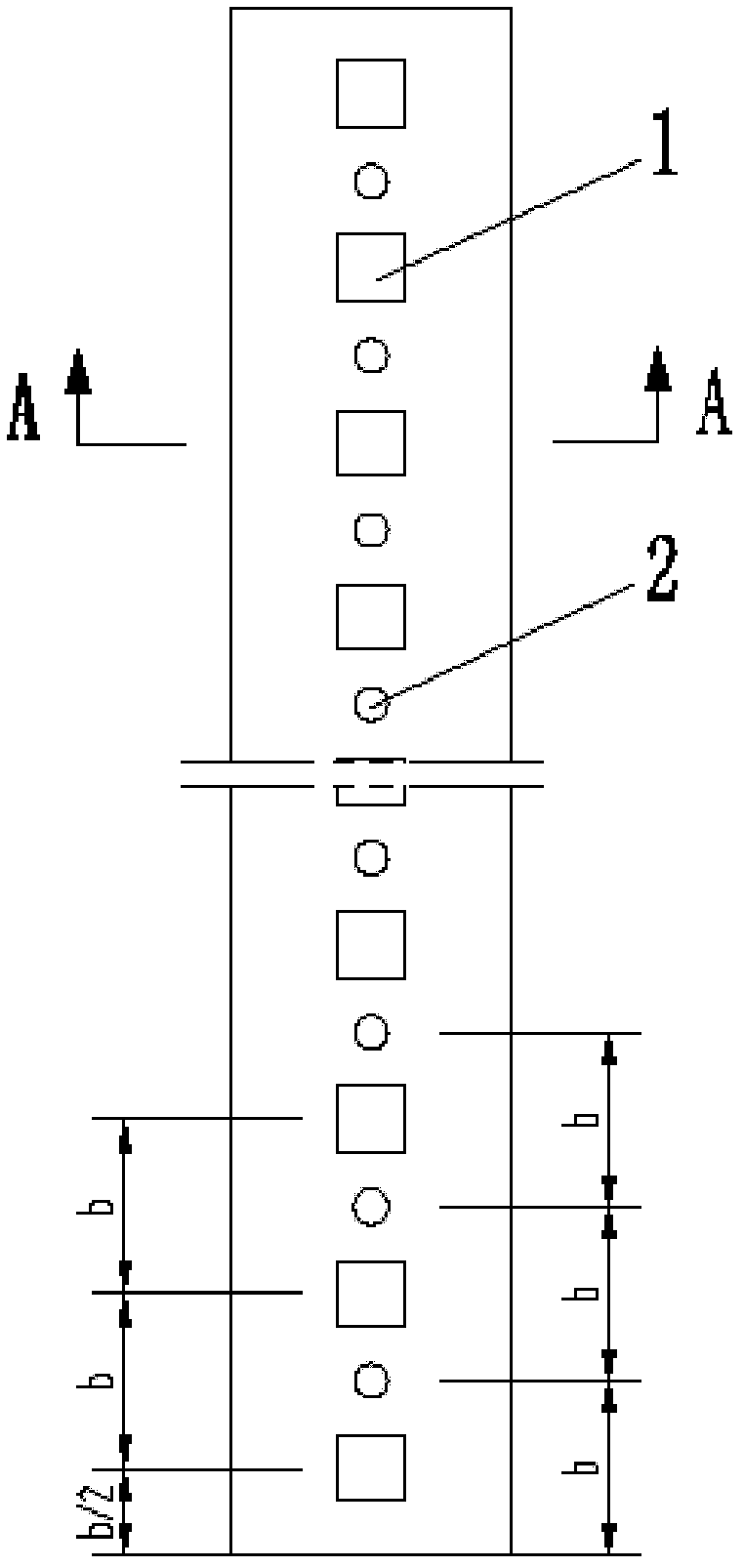

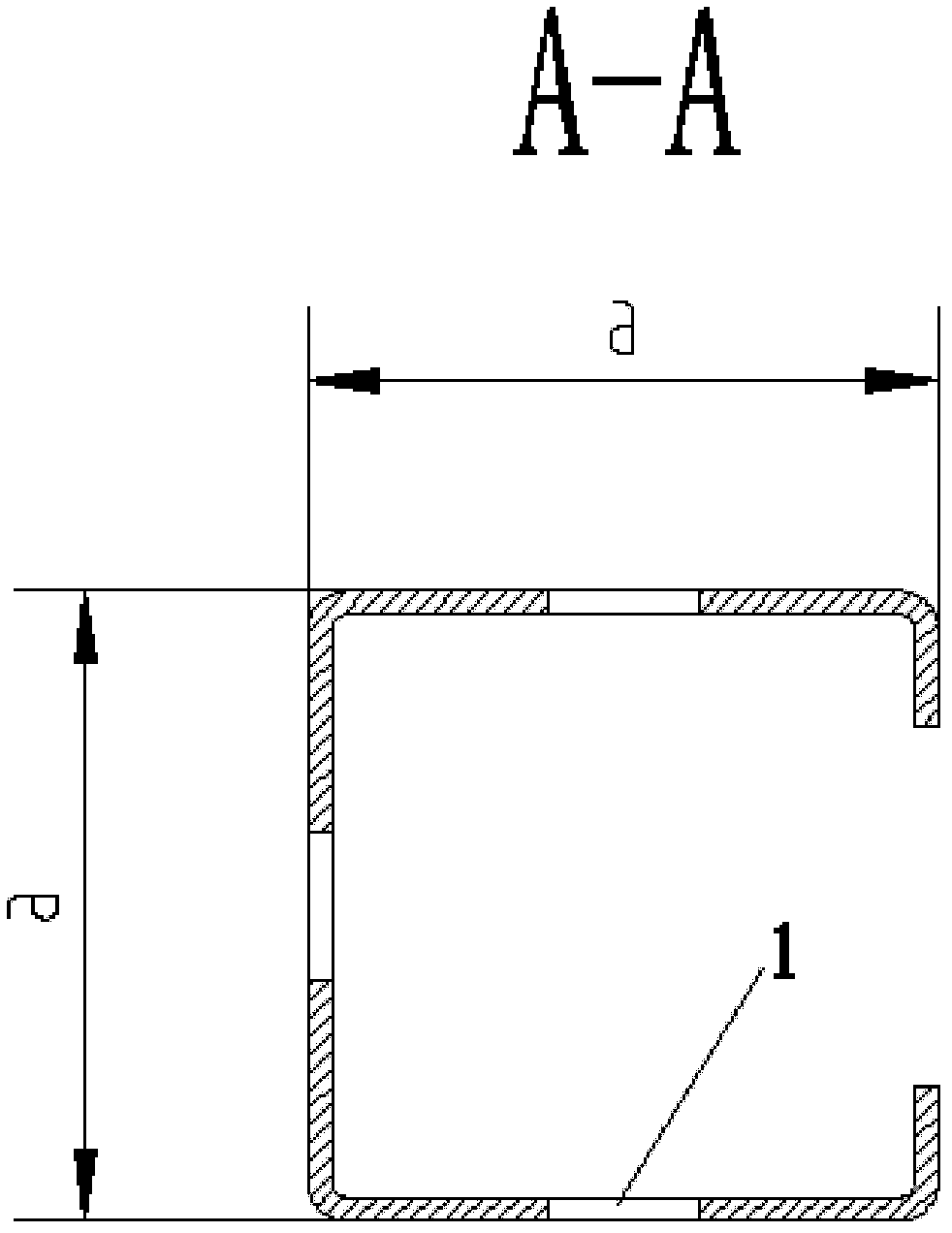

[0019] See Figure 1 to Figure 3 , this embodiment includes a keel for building a modular clean operating room.

[0020] The cross section of the keel is U-shaped. The width of the three sides of the keel is a. A plurality of square positioning holes 1 are longitudinally provided on three surfaces of the keel, and a circular positioning hole 2 is provided between every two adjacent square positioning holes 1 . The distance between two adjacent square positioning holes 1 and the distance between two adjacent circular positioning holes 2 are equal to b. The distance between the square positioning hole 1 at the end of the keel and the end face of the keel is b / 2. The standard length of the keel is six meters, and it can be truncated according to the actual size required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com