Automatic cloth spreading machine

A folding machine and automatic technology, applied in the direction of folding thin materials, object supply, packaging, etc., can solve the problems of low production efficiency, unstable production rate, high production cost, etc., to reduce labor costs, improve production efficiency and production stability , to ensure the effect of appearance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

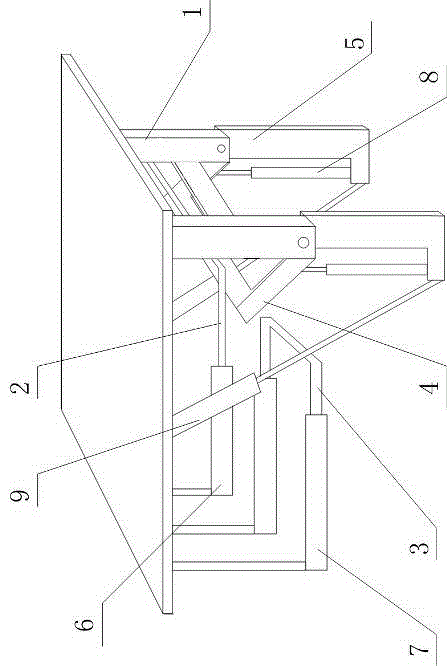

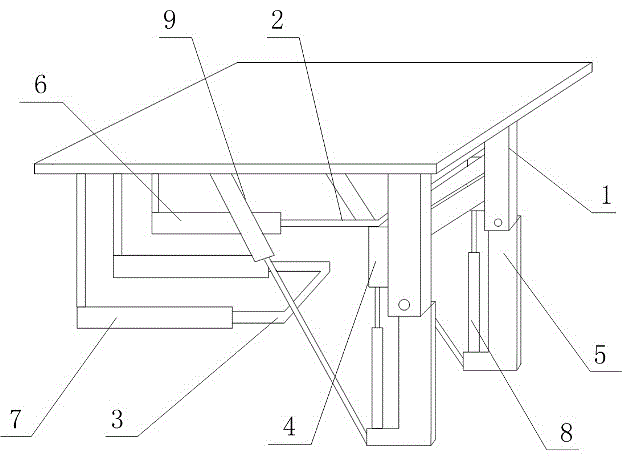

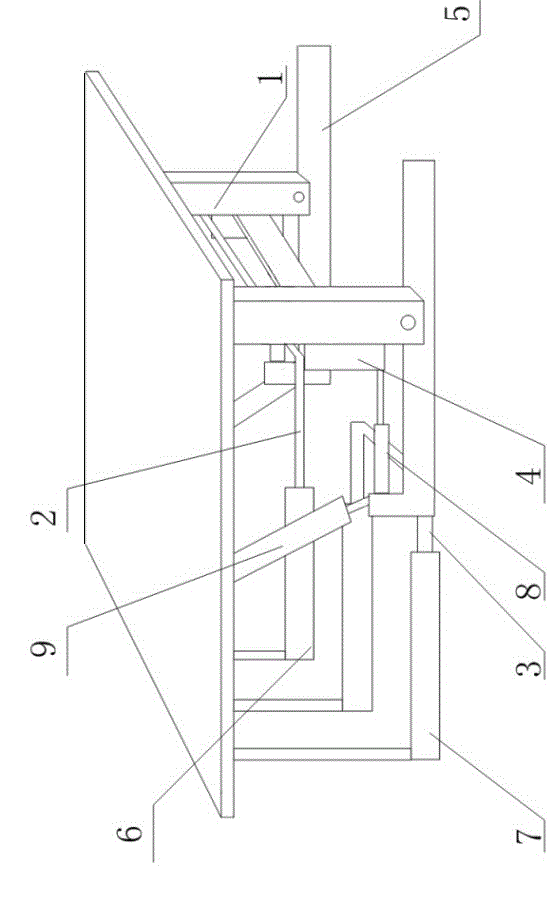

[0016] A kind of automatic folding machine of present embodiment, as Figure 1 ~ Figure 4 As shown, it includes a cloth stacking device. The cloth stacking device includes a bracket 1, a cloth straightening rod 2 is arranged at the upper end of the bracket 1, a cloth pushing rod 3 is arranged at the lower end of the bracket 1, and a wrapping rod 3 is arranged at the lower end of the bracket 1. Its rotating cloth clip 4 and cloth turning frame 5, cloth straightening rod 2, cloth pushing rod 3, cloth clip 4 and cloth turning frame 5 are respectively connected with cloth straightening cylinder 6, cloth pushing cylinder 7, cloth clamping cylinder 8 and turning over Cylinder 9 is connected, cloth straightening cylinder 6 and cloth pushing cylinder 7 respectively drive cloth straightening rod 2 and cloth pushing rod 3 to reciprocate horizontally, cloth clamping cylinder 8 and turning cylinder 9 respectively drive cloth clamping clamp 4 and cloth turning frame 5 around support 1 turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com