A light truck cab front wall assembly

A cab and assembly technology, applied to upper structure sub-assemblies, vehicle parts, upper structure of trucks, etc., can solve the problems of inability to guarantee the living space of the occupants, weak stiffness and strength of the front wall assembly, etc., and achieve Improve strength, improve crash safety performance, and reduce collapse deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention are described in detail below through examples. It should be understood that the following examples can only be interpreted as explanations and descriptions of the technical solutions of the present invention and cannot be interpreted as limitations on the technical solutions of the present invention.

[0019] The inner side and the outer side mentioned in the present invention are relative concepts, which conform to the common understanding of those skilled in the art; the left side and the right side refer to the left side and the right side when facing the front view of the dash outer panel; The above and below are relative concepts, which are only used to describe the technical solution of the present invention.

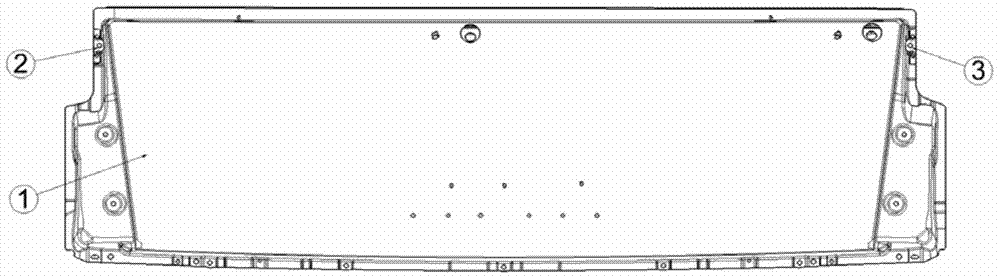

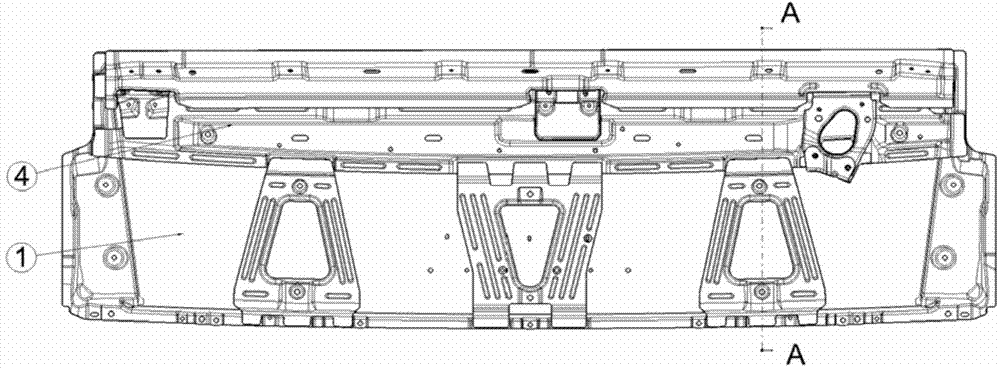

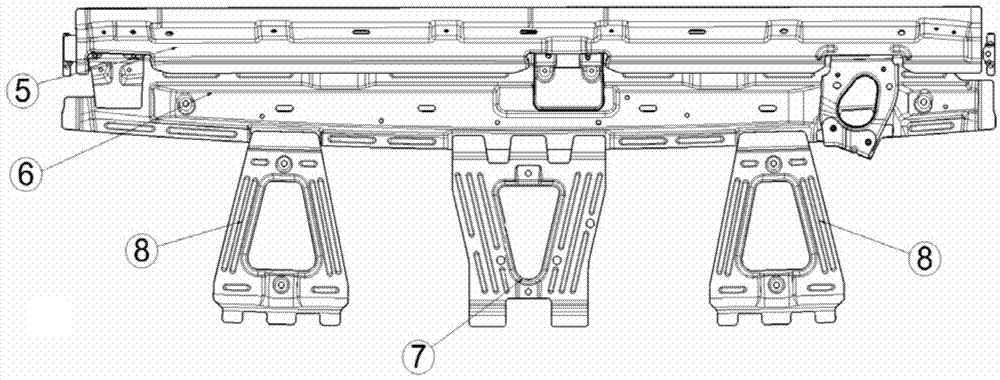

[0020] see figure 1 , figure 2 , a light truck cab cowl assembly, comprising a cowl outer panel 1 protruding from the outer surface, a bracket 2 fixed on the left side panel of the cowl outer panel, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com