Upright vacuum cleaner

A technology for vacuum cleaners and vacuum cleaners, applied in the directions of vacuum cleaners, suction hoses, cleaning equipment, etc., can solve the problems of heavy, bulky, and large cleaner heads, and achieve the effect of reducing material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

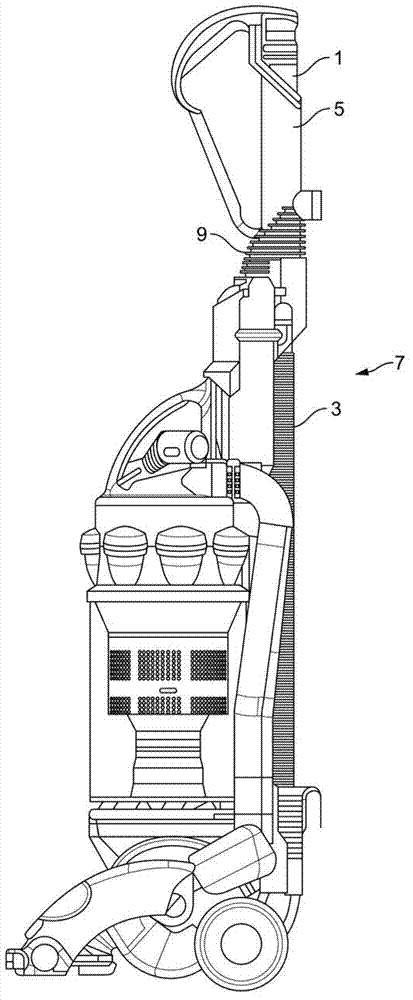

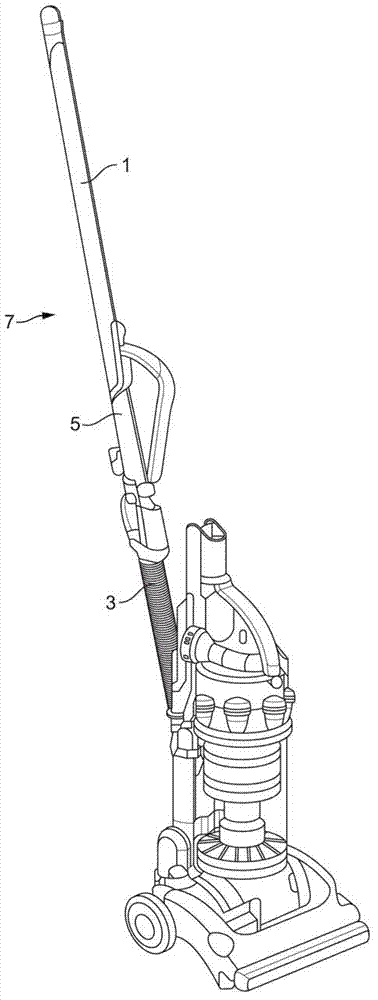

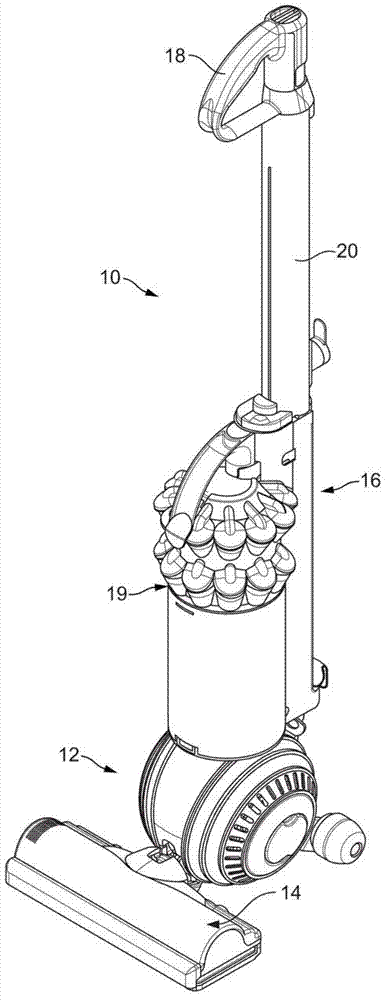

[0047] image 3 An upright vacuum cleaner 10 is shown.

[0048] The vacuum cleaner 10 has a rolling head assembly 12 which carries a stationary cleaner head 14 and a "upright" body 16 which is tiltable relative to the head assembly 12 and which includes a handle 18 for maneuvering the cleaner 10 over ground. In use, the user grasps the handle 18 and tilts the upright body 16 until the handle 18 is positioned at a height convenient for the user; the user can then use the handle 18 to roll the vacuum cleaner 10 over the ground to facilitate collecting dust on the ground or other debris. Dust and debris are drawn through a downwardly facing suction inlet on the cleaner head 14 by a motor-driven fan housed on the cleaner 10 . From here, the dust laden air stream is conveyed in conventional manner under the suction pressure generated by the fan to the cyclonic separation device 19 where the dust is separated from the air and the relatively clean air is then discharged back into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com