Automatic garlic root cutting machine based on image processing technique

An image processing and umbilical cutting machine technology, applied in food processing, application, food science and other directions, can solve the problems of no protection mechanism, loss, miscutting of garlic, etc., to avoid miscut operation, ensure stability, and realize man-machine interactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

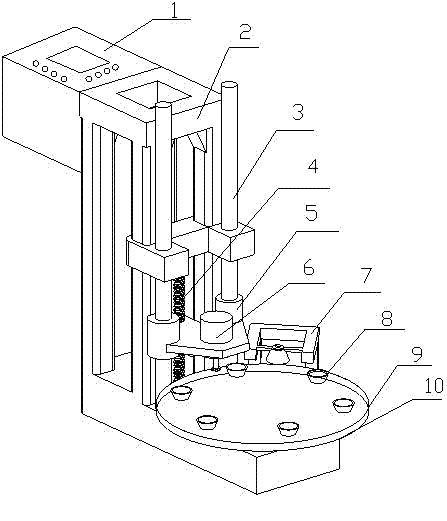

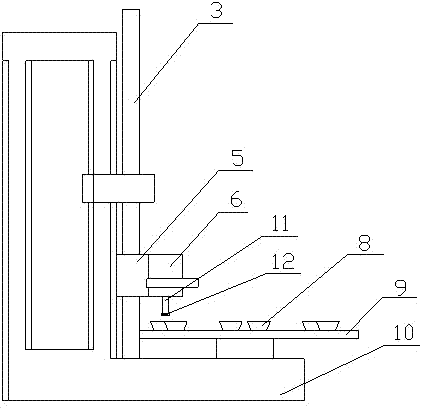

[0025] The automatic garlic cutting umbilical machine based on image processing technology includes a base 10, a frame 2 and a control box 1 installed on the frame 2, a material conveying mechanism, a cutting mechanism and an image acquisition mechanism, and the control box 1 is connected to the material conveying mechanism respectively. The mechanism, the cutting mechanism and the image acquisition mechanism are connected.

[0026] Described material conveying mechanism comprises drive motor 1 and material tray 9 that are located on base 10, and the below of described material tray 9 is provided with speed reducer, and described material tray 9 links to each other with drive motor 1 by speed reducer; Positioning piles are arranged above 9, and the position of the material cup 8 is fixed by the positioning piles; the material cups 8 are evenly distributed on the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com