Banana jam and preparation method thereof

A kind of technology of banana pulp and banana, applied in the field of jam and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of banana jam of the present invention includes the following steps:

[0029] 1. Dry banana powder: Using SDF-300B hammer mill, crush 75-85 parts of dry banana slices to an average particle size ≤40μm according to the mass ratio to obtain dry banana powder. The crushed dry banana powder can improve the subsequent steps. The uniformity of mixing can better maintain the flavor of banana jam.

[0030] 2. Peeling fresh bananas: manually peel 90-110 kg of fresh bananas, and the quality of the banana pulp obtained after peeling is 90-94% of that before peeling.

[0031] 3. Color protection: blanch the peeled banana pulp in hot water at 100°C for 2 minutes until the core temperature reaches 85°C. The color protection makes the finished product bright and beautiful, and can inhibit microbial pollution; in step 5, the banana pulp will be in contact with the air in the beating machine, and the high temperature can inactivate the polyphenol oxidase activity in the...

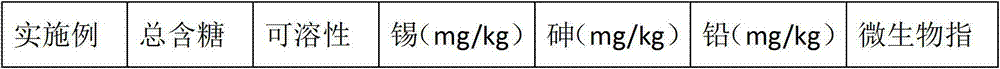

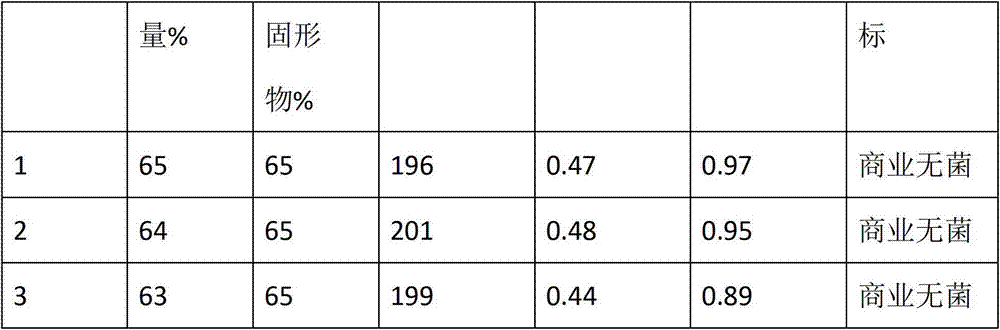

Embodiment 1

[0039] 1. Crush 75kg of dried banana slices to an average particle size of ≤40μm to prepare dry banana powder.

[0040] 2. Manually peel 90 kg of fresh bananas.

[0041] 3. Color protection: Blanch the peeled banana pulp in hot water at 100°C for 2 minutes.

[0042] 4. Using the BZJ type orange and tangerine slicing juicer, squeeze 2.5 kg of lemon to obtain lemon juice.

[0043] V. Beating: The banana pulp after color protection is beaten once with a beater with a sieve aperture of 0.8mm.

[0044] 6. Ingredients: mix 90kg of white granulated sugar into a sugar solution with a concentration of 75%.

[0045] 7. Concentration: Put the sugar solution, mashed banana, dry banana powder, 15kg milk powder into the jacketed pot and stir while heating. The temperature in the pot is 100℃, the stirring speed is 36r / min, and after concentration for 10 minutes, add lemon juice and continue. Stir at a speed of 36r / min and concentrate until the soluble solid content is 65%, stop heating, take out the p...

Embodiment 2

[0049] 1. Crush 80kg dry banana slices to an average particle size ≤40μm.

[0050] 2. Peel 100kg fresh bananas by hand.

[0051] 3. Color protection: Blanch the peeled banana pulp in hot water at 100°C for 2 minutes.

[0052] 4. Using the BZJ type orange and tangerine slicing juicer, squeeze 3kg of lemon to obtain lemon juice.

[0053] 5. Beating: The banana pulp after color protection is beaten once with a beater with a sieve aperture of 1.0mm.

[0054] 6. Ingredients: 100kg white granulated sugar is mixed into a sugar solution with a concentration of 75%.

[0055] 7. Concentration: Put the sugar solution, mashed banana, dry banana powder, 20kg milk powder into the jacketed pot and stir while heating. The temperature in the pot is 100℃, the stirring speed is 36r / min, and after concentration for 10 minutes, add lemon juice and continue to Stir at a speed of 36r / min, and when concentrated to a soluble solid content of 65%, stop heating and take out the pot to obtain banana jam.

[0056] 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com