Spinosad and chlopyrifos compound microsphere suspending agent and preparation method thereof

A spinosyn and chlorpyrifos technology, applied in botanical equipment and methods, insecticides, biocides, etc., can solve the problems of high prevention and control costs, large environmental pollution, and low prevention and control costs, and achieve outstanding control effects and insecticidal effects. Broad spectrum, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

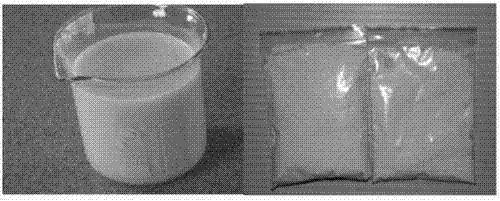

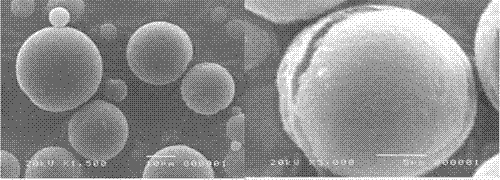

[0040] The concrete steps of the preparation method of this spinosad chlorpyrifos microsphere suspension are as follows:

[0041] The preparation method of spinosad chlorpyrifos microspheres: raw material proportioning is weighed respectively, and certain quality spinosad chlorpyrifos technical substance and polylactic acid mixed in proportion are dissolved in dichloromethane, sealed with plastic wrap and placed in an ice water bath In the process, after the two are fully dissolved (weigh before and after dissolving to make up for the lost dichloromethane), inject a certain amount of emulsifier and 0.05% volume percentage of the SPAN-80 aqueous solution with a syringe, and use Emulsify with a high-speed internal cutting homogenizer at 2800-4500 r / min for 0.2-1.0 min to obtain primary emulsion, add about 0.3 mL of silicone defoamer, and quickly pour the resulting solution into a magnetic stirrer equipped with 1 L of water In a large beaker, keep the reaction temperature at 30 °...

Embodiment 1

[0060] Raw material ratio is weighed respectively, 0.4g is by mass ratio (m 多素 : m 毒 =1 : 20) Dissolve the mixed spinosad chlorpyrifos technical product and 1.2g polylactic acid in 10mL of dichloromethane, seal it with plastic wrap and place it in an ice water bath. Make up for the lost dichloromethane), inject the drug solution into 200mL, 17.5mg / mL gum arabic and 0.05% by volume SPAN-80 aqueous solution with a syringe, and emulsify with a high-speed internal cutting homogenizer at 4000 r / min After 0.5 min, the initial emulsion was prepared, and about 0.3 mL of silicone defoamer was added, and the resulting solution was quickly poured into a large beaker with 1 L of water on a magnetic stirrer, and the reaction temperature was kept at 30 °C. Stir at high speed at r / min until there is no smell of dichloromethane. Centrifuge, filter and separate the solids and place them in a constant temperature drying oven at 40 ℃ to dry, that is spinosad · chlorpyrifos microspheres.

[...

Embodiment 2

[0064] Raw material ratio is weighed respectively, 0.4g is by mass ratio (m 多素 : m 毒 =1 : 13) Dissolve the mixed spinosad chlorpyrifos technical product and 1.2g polylactic acid in 10mL of dichloromethane, seal it with plastic wrap and place it in an ice water bath. Make up for the lost dichloromethane), inject the drug solution into 200mL, 17.5mg / mL gum arabic and 0.05% by volume SPAN-80 aqueous solution with a syringe, and emulsify with a high-speed internal homogenizer at 3500 r / min After 0.5 min, the initial emulsion was prepared, and about 0.3 mL of silicone defoamer was added, and the resulting solution was quickly poured into a large beaker with 1 L of water on a magnetic stirrer, and the reaction temperature was kept at 30 °C. Stir at high speed at r / min until there is no smell of dichloromethane. Centrifuge, filter and separate the solids, and dry them in a constant temperature drying oven at 40°C, namely spinosad chlorpyrifos microspheres.

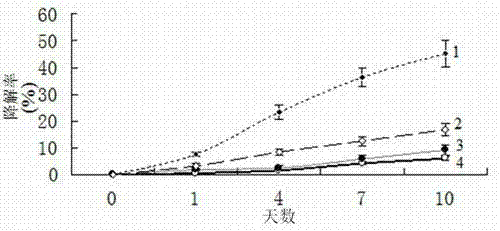

[0065] Take a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com