Exhaust gas evacuation device for internal combustion engine

A technology of exhaust device and internal combustion engine, which is applied in the direction of exhaust device, diagnosis device of exhaust gas treatment device, internal combustion piston engine, etc., can solve the problem of not judging the regeneration period and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]

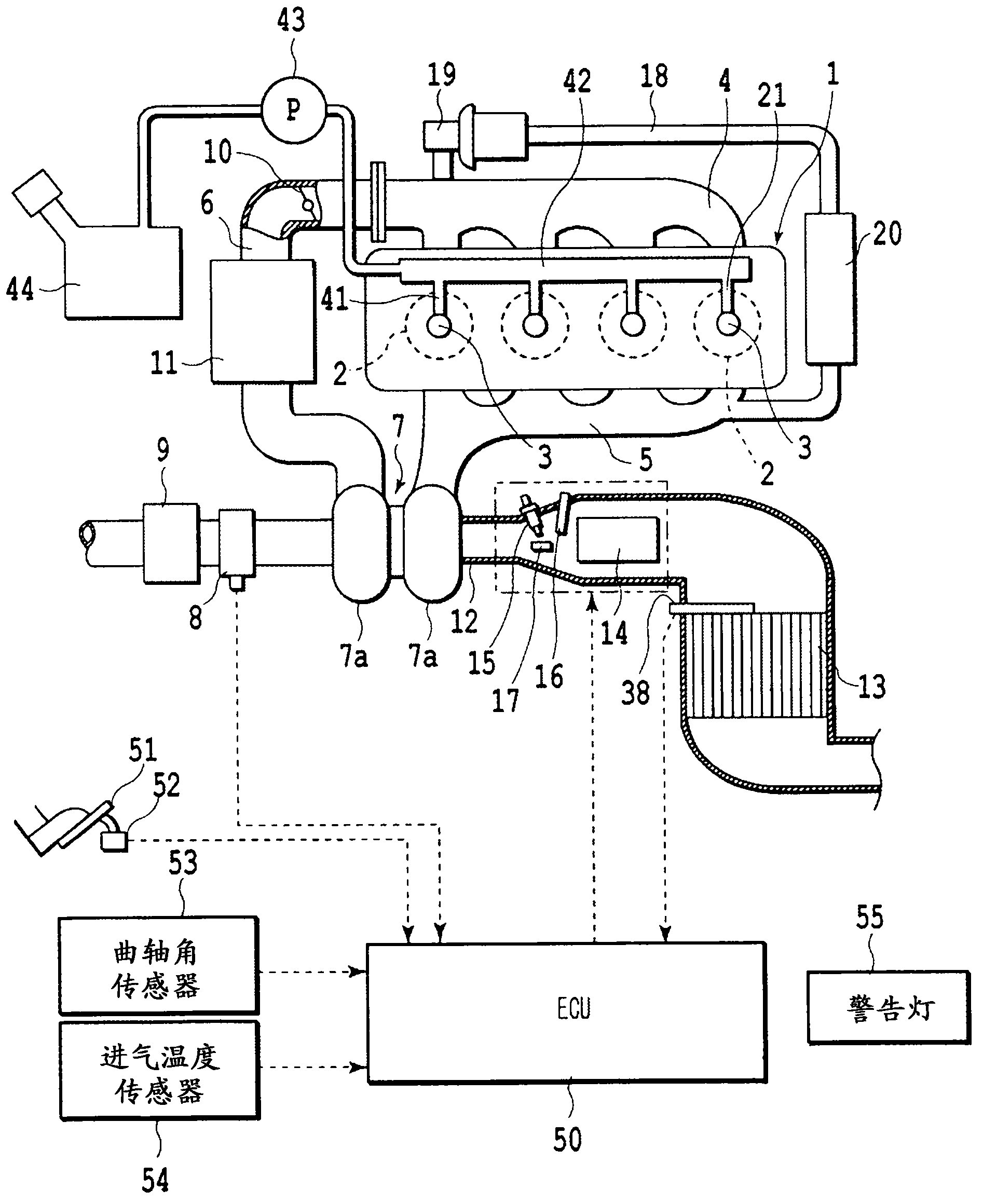

[0039] Next, preferred embodiments of the present invention will be described in detail. figure 1 The first embodiment of the present invention is shown. exist figure 1 In the above, the engine body 1 is a compression ignition internal combustion engine (diesel engine) fueled by light oil, but it may also be other types of internal combustion engines. The engine block 1 has a combustion chamber 2 in each of four cylinders. An electronically controlled injector 3 for injecting fuel is arranged in each combustion chamber 2 . An intake manifold 4 and an exhaust manifold 5 are connected to the combustion chamber 2 . The intake manifold 4 is connected to an outlet of a compressor 7 a of an exhaust turbocharger 7 via an intake pipe 6 , and an inlet of the compressor 7 a is connected to an air filter 9 via an air flow meter 8 . The upstream side of the air cleaner 9 is open to the atmosphere.

[0040] A throttle valve 10 driven by a stepping motor is arranged in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com