Battery heating system of electric automobile

A battery heating system, electric vehicle technology, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as poor heating efficiency, and achieve the effects of good heating consistency, uniform heat distribution, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

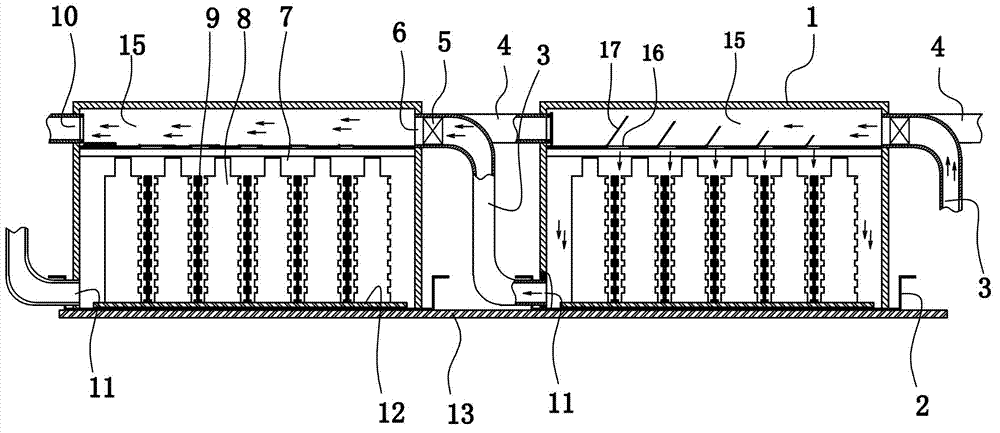

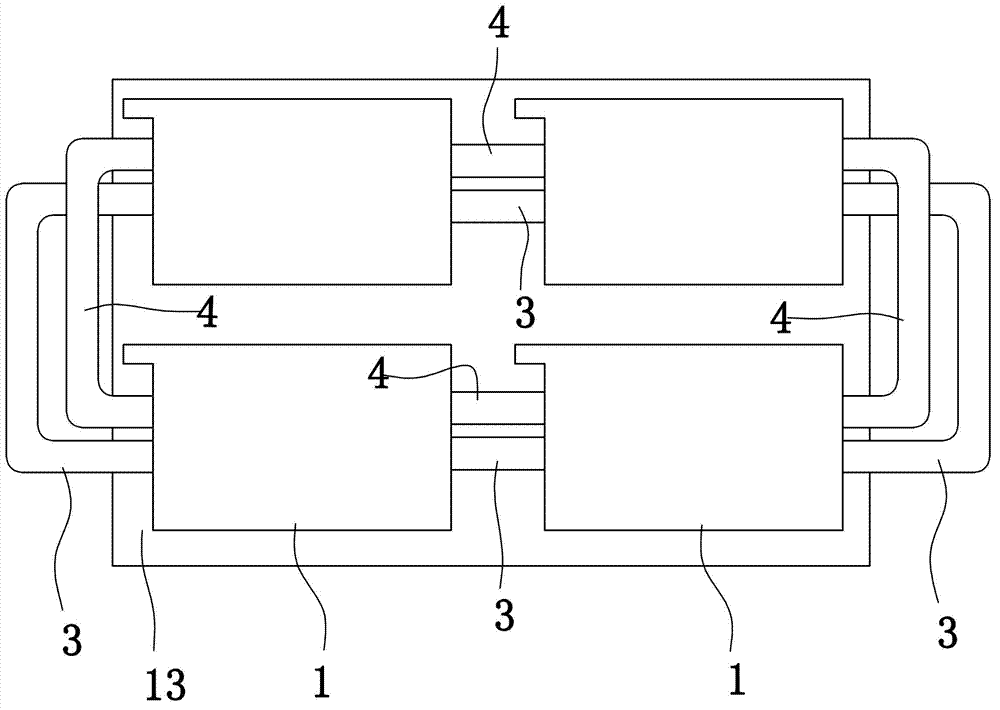

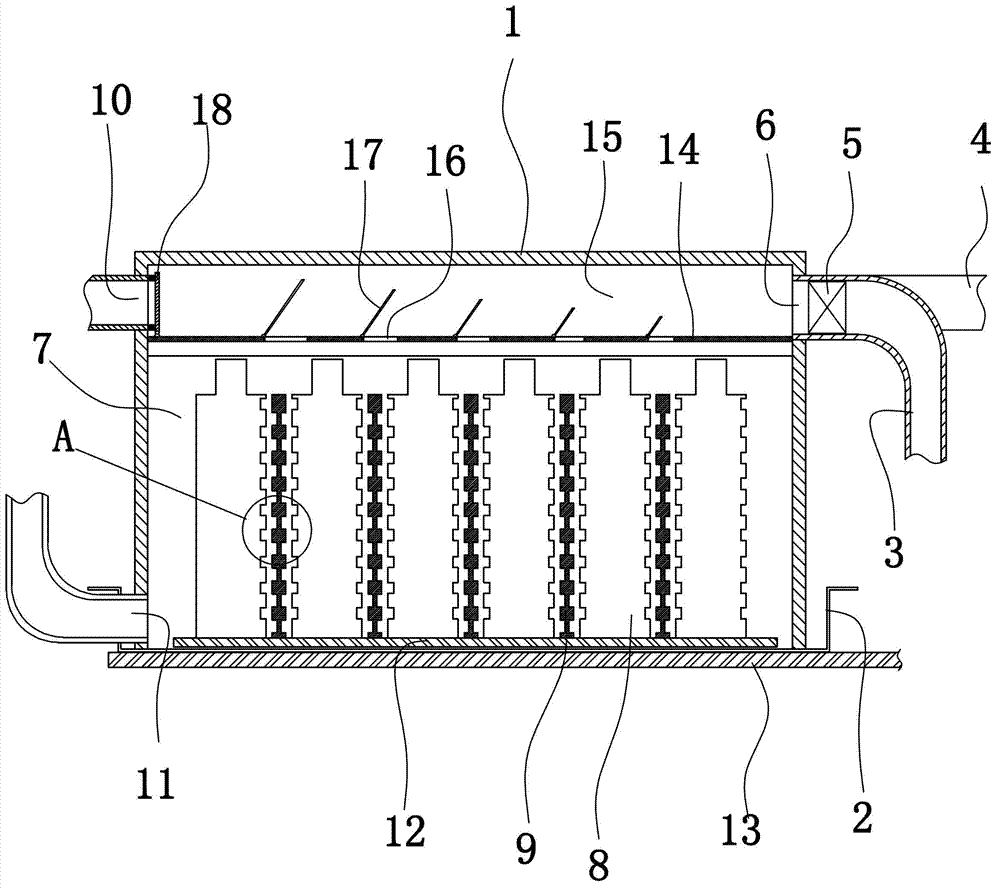

[0032] Such as figure 1 , figure 2 As shown, a battery heating system for an electric vehicle includes a controller, four mounting plates 2 and four battery modules 7 . Each battery module group 7 is fixed in the battery box through the mounting plate 2 . Each battery module 7 has several battery cells 8 inside. Each mounting plate 2 is correspondingly provided with a thermal insulation shell 1 . The thermal insulation shell 1 is rectangular. Each battery module 7 is correspondingly arranged in a sealed cavity formed by the mounting plate 2 and the heat-insulating casing 1 . A temperature sensor is arranged in each heat insulating shell 1 .

[0033] Such as image 3 , Figure 5 As shown, each battery module is provided with several electric heating sheets 9 , and each electric heating sheet 9 is respectively arranged between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com