Tunneling magneto-resistance multilayer film material

A technology of tunneling magnetoresistance and multi-layer film, applied in the direction of material selection, etc., can solve problems such as the adverse effect of spin polarizability magnetoresistance, and achieve good spin polarization performance, good mutual compatibility, and maintain the interface. The effect of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

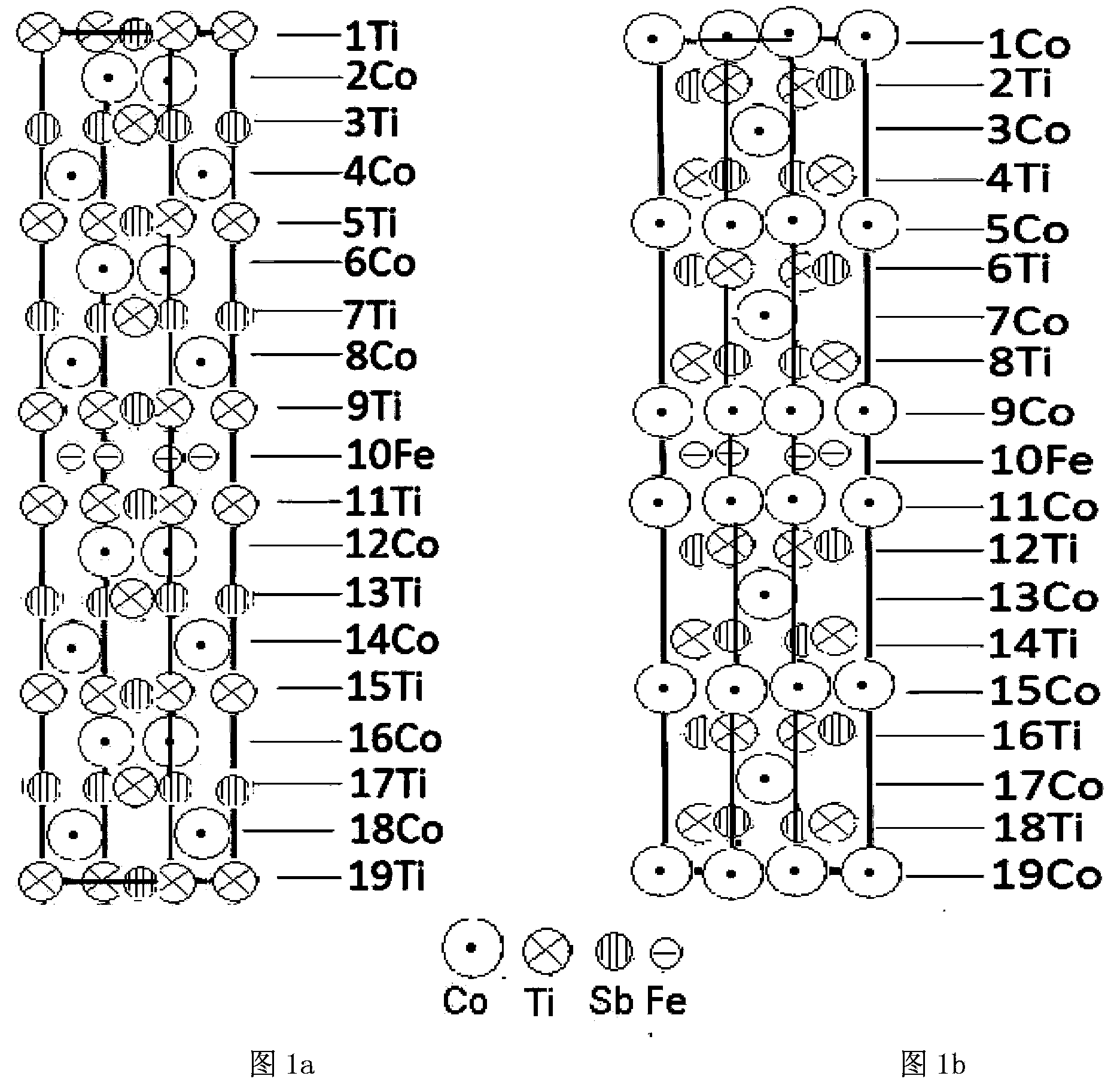

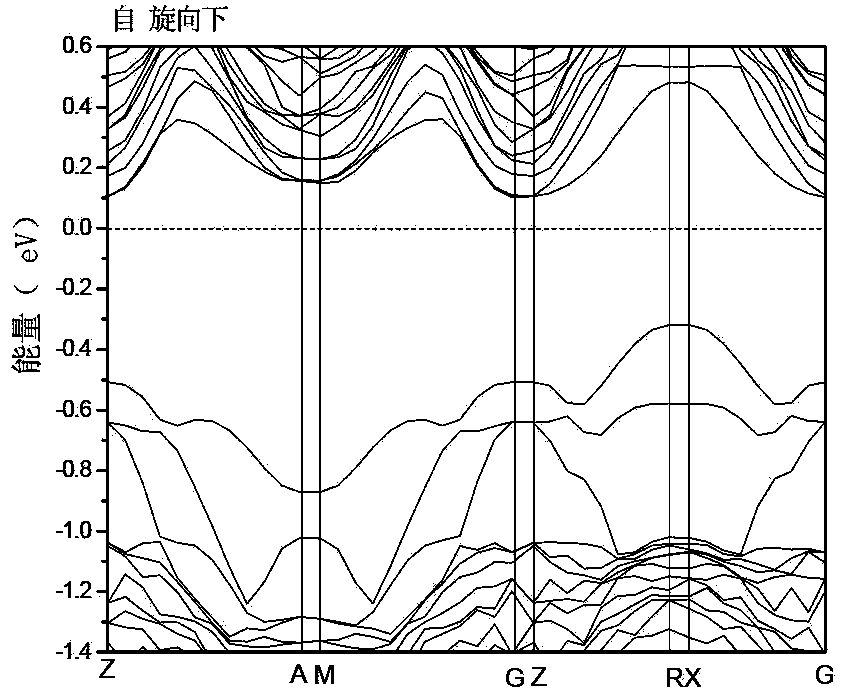

[0024] Preparation of (CoTiSb) with 1 Fe atomic layer and Fe-Co interface and Fe-TiSb interface 5 / Fe 1 / (CoTiSb) 5 TMR multilayer film material with superlattice structure.

[0025] The CoTiSb single crystal is prepared by pulling method. In order to obtain the Fe-Co interface and the Fe-TiSb interface, a layer of Co or TiSb atomic layer and a layer of Fe atoms are grown sequentially on the CoTiSb single crystal sample by molecular beam epitaxy. layer, and then grow a Co layer or TiSb layer on the Fe atomic layer, and then alternately grow a TiSb layer or Co layer, so that a CoTiSb with a Fe-Co interface and a Fe-TiSb interface with a Fe atomic layer is prepared. TMR multilayer film material with / Fe / CoTiSb superlattice structure. The specific process is as follows:

[0026] The first step, CoTiSb single crystal pulling

[0027] The cooling water outlet temperature is stable within the range of 25±10°C, and the vacuum pressure is not greater than 6×10 during the whole pr...

Embodiment 2

[0052] Preparation of (CoTiSb) with two Fe atomic layers and Fe-Co interface and Fe-TiSb interface 10 / Fe 2 / (CoTiSb) 10 TMR multilayer film material with superlattice structure.

[0053] The difference from Example 1 is that a Co-Fe-TiSb interface is produced when there are two layers of Fe atomic layers. In the actual growth process, a layer of Co is first grown on the CoTiSb single crystal by molecular beam epitaxy. Then grow two Fe atomic layers on the Co layer. The thickness of the Fe atomic layer is 0.29nm. The annealing time of step (9) in Example 1 is extended to 3 hours, and then alternately grow TiSb layers and Co on the Fe atomic layer. Layer, the thickness of the grown CoTiSb atomic layer is controlled to be 1nm, thereby growing a CoTiSb / Fe / CoTiSb film comprising two Fe atomic layers with a Co-Fe-TiSb interface, and other processes are the same as in Example 1.

[0054] TMR of a CoTiSb / Fe / CoTiSb superlattice structure with 2 layers of Fe atomic layers and Fe-Co ...

Embodiment 3

[0057] Preparation of (CoTiSb) with 3 Fe atomic layers and Fe-Co interface and Fe-TiSb interface 15 / Fe 3 / (CoTiSb) 15 TMR multilayer film material with superlattice structure.

[0058] The difference from Example 1 is: the thickness of the Fe atomic layer is three atomic layers, and the thickness is 0.435nm. In real-time observation, when the Fe atomic layer reaches a thickness of three atomic layers, the thickness of the grown CoTiSb atomic layer is 1.5nm. The annealing time of step (9) in Example 1 was extended to 4 hours. Using this method, a multilayer film material with a high spin polarizability greater than 90% at both the Fe-TiSb interface and the Fe-Co interface was obtained. The other processes were the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com