High-precision large-caliber electric reflecting mirror frame based on orthogonal axis

A reflective mirror frame, high-precision technology, applied in installation, optics, instruments, etc., can solve the problems of poor beam flexibility, inaccuracy, and difficult control of laser beams, improve repeat positioning accuracy and stability, and realize two-dimensional angles Effect of adjustment, reduction of deformation and installation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

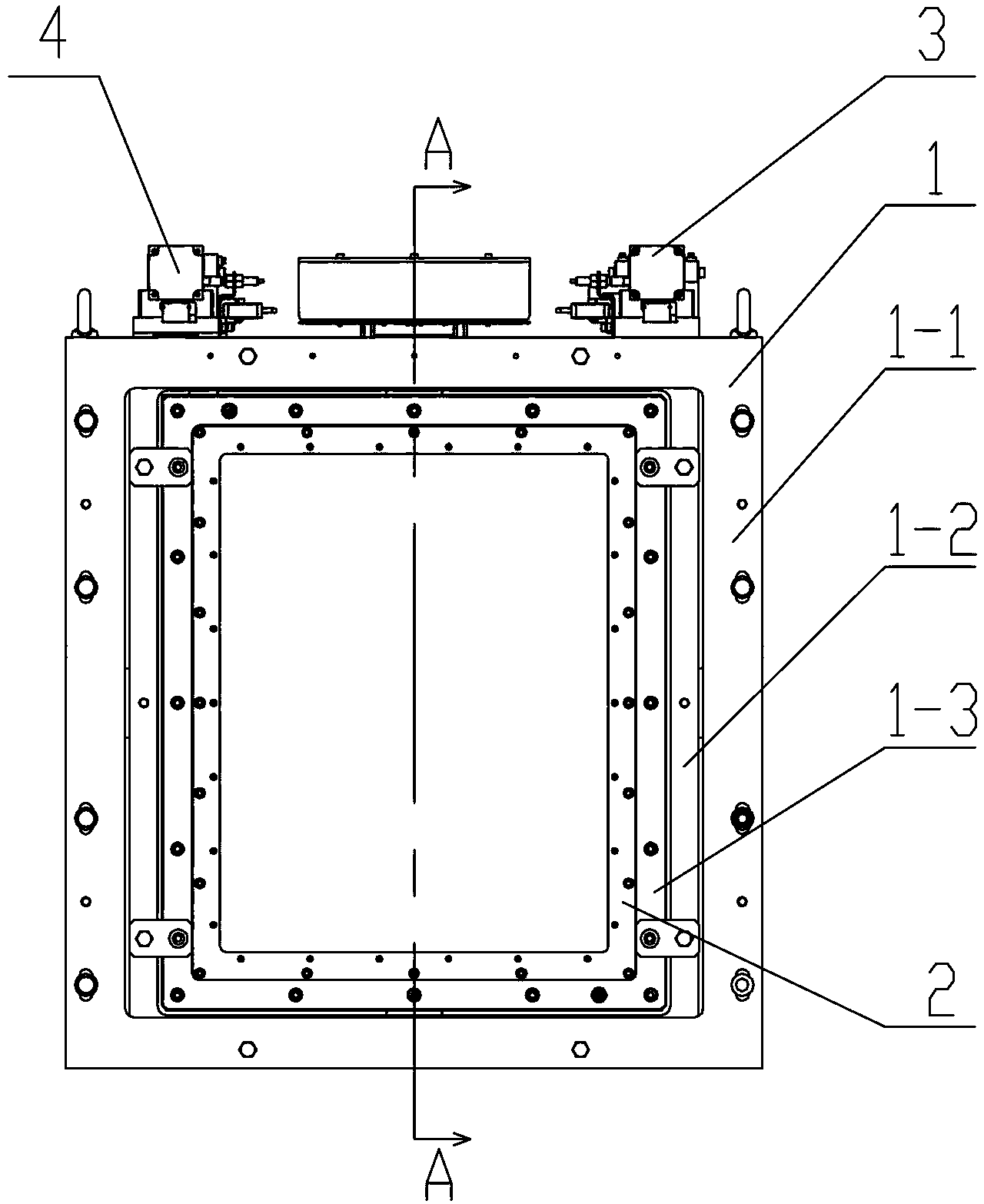

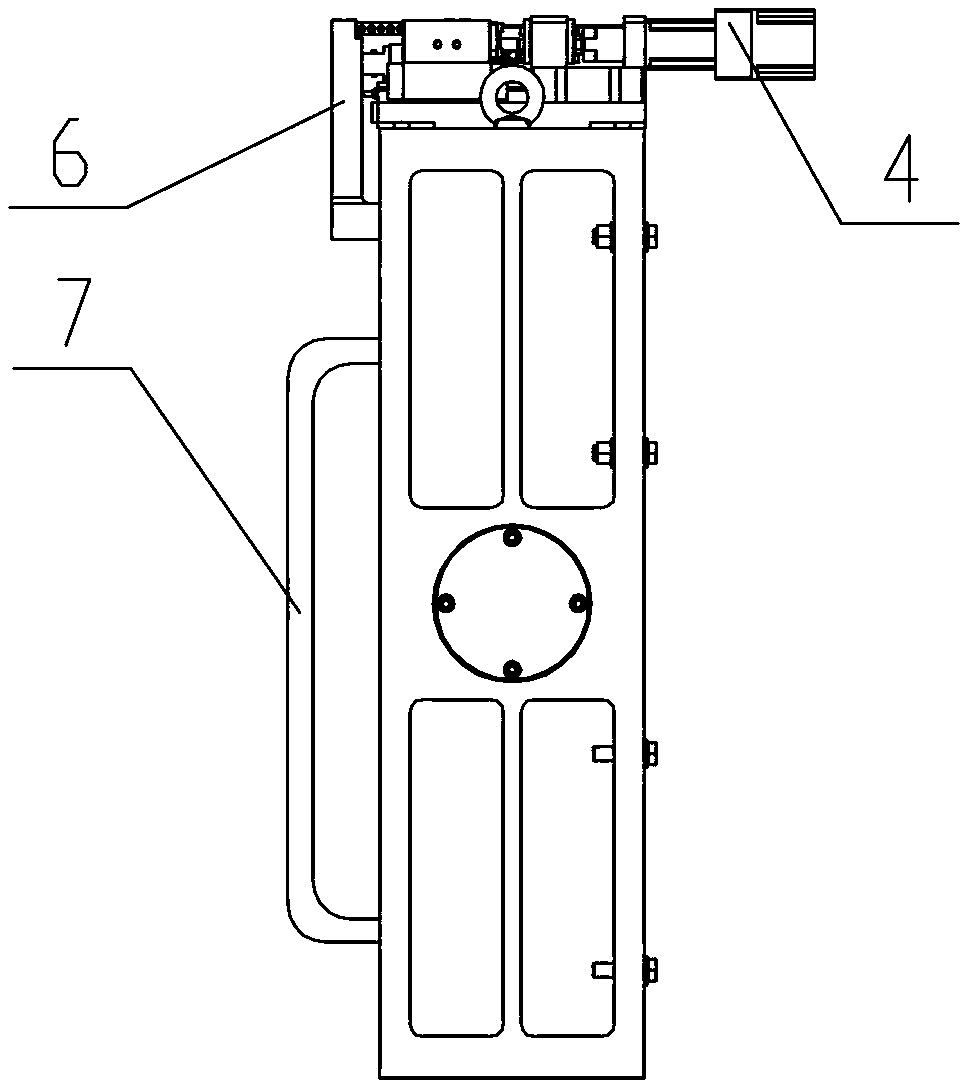

[0014] Specific implementation mode one: combine Figure 1 to Figure 14 Describe this embodiment, the high-precision large-diameter motorized mirror frame in this embodiment includes a mirror frame base assembly 1, a transition frame assembly 2, two micro-drivers, a pitch connection block 5 and a yaw connection block 6, two The three micro-drivers are pitch axis micro-driver 3 and yaw-axis micro-driver 4 respectively. The rotating shaft 1-4, two second rotating shafts 1-5 and four pairs of bearings 1-6, the frame 1-1, the pitch shaft frame 1-2, and the yaw shaft frame 1-3 are all rectangular structures, and the two horizontally arranged A first rotating shaft 1-4 passes through two vertical frames of the frame 1-1, and the frame 1-1 establishes a connection relationship with the pitch axis frame 1-2 through the first rotating shaft 1-4, each first A pair of bearings 1-6 is arranged between the rotating shaft 1-4 and the frame 1-1, the pitching axis frame 1-2 is adjusted for t...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 and Figure 8 This embodiment will be described. In this embodiment, the bearings 1-6 are high-precision angular contact ball bearings. Bearings arranged in this way enable the invention of the present invention to be most effective. Two high-precision angular contact ball bearings are arranged at the ends of the first rotating shaft 1-4 and the second rotating shaft 1-5 to cooperate with each other, which not only realizes the positioning and pre-tightening of the bearings, but also reduces the impact of the pre-tightening force on the shaft frame. Deformation and installation errors.

[0017] For two pairs of bearings in the horizontal shaft system, one pair of bearings is arranged face-to-face, and the other pair of bearings is arranged back-to-back; for two pairs of bearings in the vertical shaft system, one pair of bearings is arranged face-to-face, and the other pair of bearings is arranged back...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 This embodiment will be described. In this embodiment, the pitch-axis micro-driver 3 and the yaw-axis micro-driver 4 are arranged symmetrically with respect to the vertical centerline of the mirror frame base assembly 1 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com