Detecting method for displacement of hydraulic counter-blow hammer heads

A detection method and counter-hammer technology, applied in measuring devices, instruments, electrical devices, etc., can solve the problems of falling off, violent vibration of the hammer head, and easy loosening of the sensor, and achieve the effect of fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

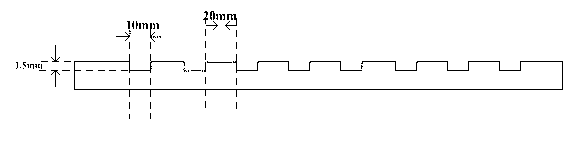

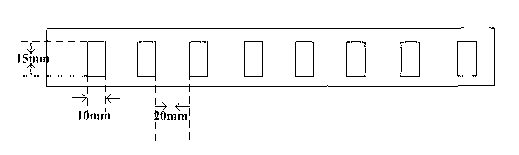

[0019] The invention engraves a groove scale with a certain length in the vertical direction on the side of the hammer head of the hydraulic counter hammer, senses the relative movement of the groove of the hammer head through the eddy current displacement sensor, and outputs a when the groove enters the sensing area of the eddy current displacement sensor A voltage signal that varies with the displacement of the hammer head. When working, the displacement of the hammer head can be determined by detecting the voltage signal output by the sensor in real time and calculating it.

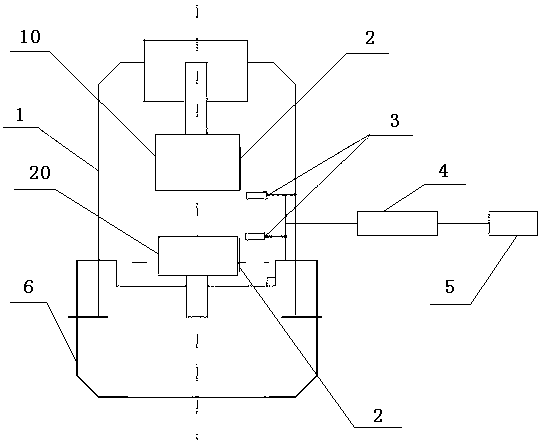

[0020] Depend on figure 1 It can be seen that the detection method includes two eddy current displacement sensors 3 , two rows of grooves 2 engraved on the upper and lower hammer heads, a data acquisition card 4 and a host computer 5 . Such as figure 1 As shown, two eddy curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com