Vibration isolation coal cutter

A shearer and vibration isolation technology, which is applied in earth-moving drilling, slitting machinery, non-rotational vibration suppression, etc. Effective isolation, reducing mining failures, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

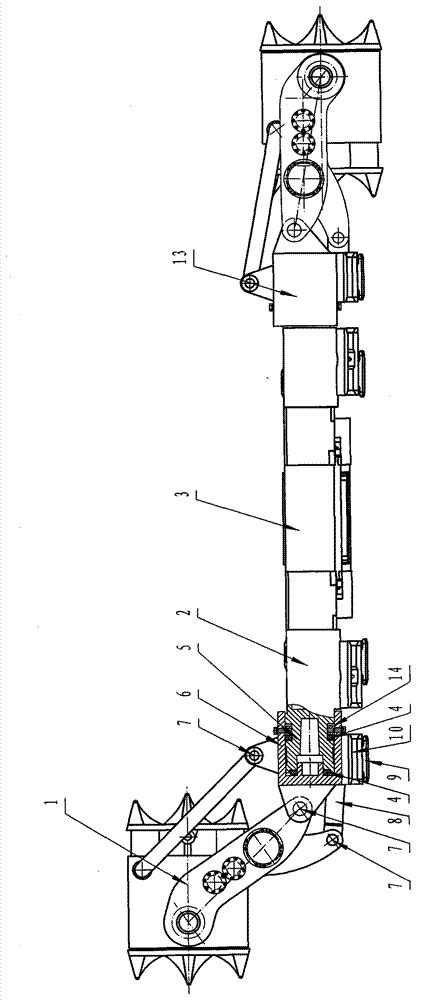

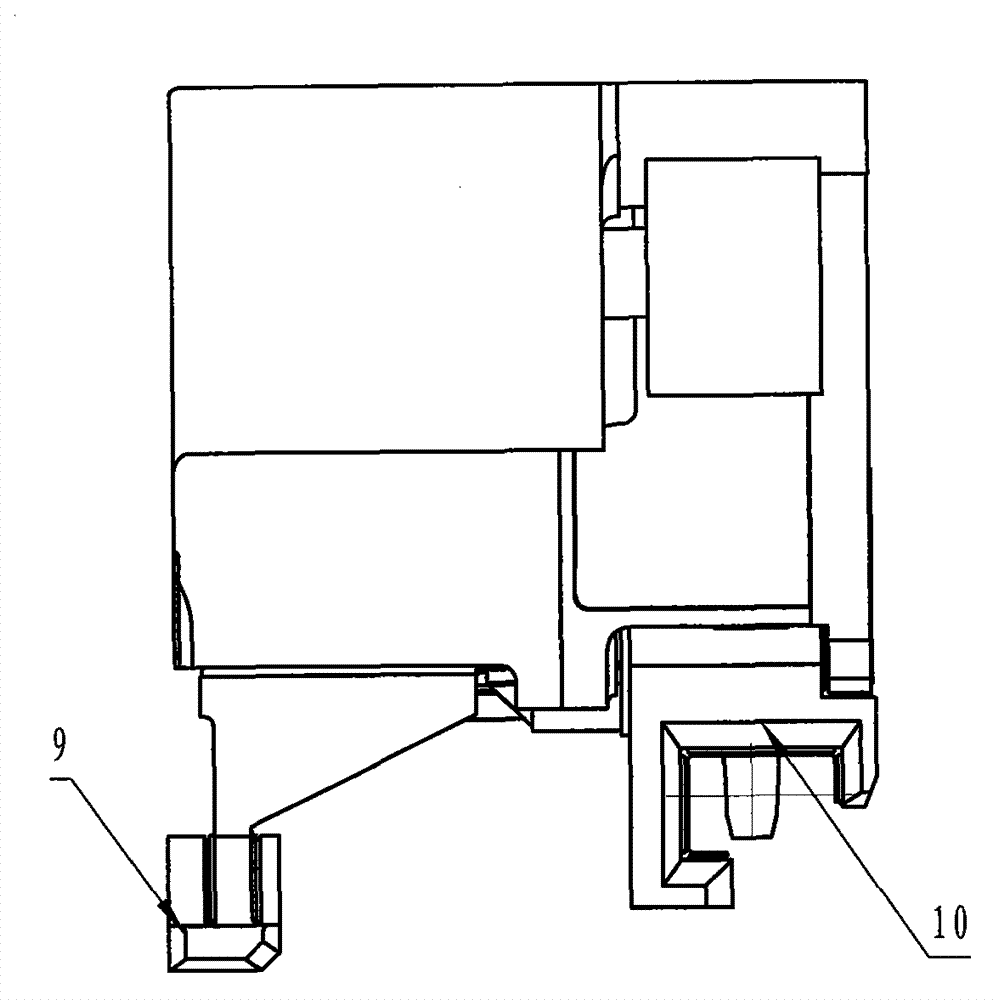

[0035] Such as Figure 1 to Figure 2 As shown, a vibration isolation shearer includes a cutting mechanism 1 and a fuselage 3. The fuselage 3 includes a traction box 2, an electric control unit, a hydraulic system, and a spray cooling system. The gap between the cutting mechanism 1 and the fuselage 3 is A buffer mechanism 13 is provided, the traction box 2 is provided with a guide piece, the buffer mechanism 13 is provided with a guide sleeve 6 matched with the guide piece 5, a buffer 4 is arranged between the guide piece 5 and the guide sleeve 6, and the fuselage 3 includes a walking device, the cutting mechanism 1 is arranged on the buffer mechanism 13, the traveling device drives the buffer mechanism 13 to travel, and the cutting mechanism 1 continuously cuts coal mining.

[0036] The guide sleeve 6 is provided with a backstop 14, and the backstop 14 cooperates with the guide 5 to stop back.

[0037] The guide piece 5 is slidably connected with the guide sleeve 6, and the b...

Embodiment 2

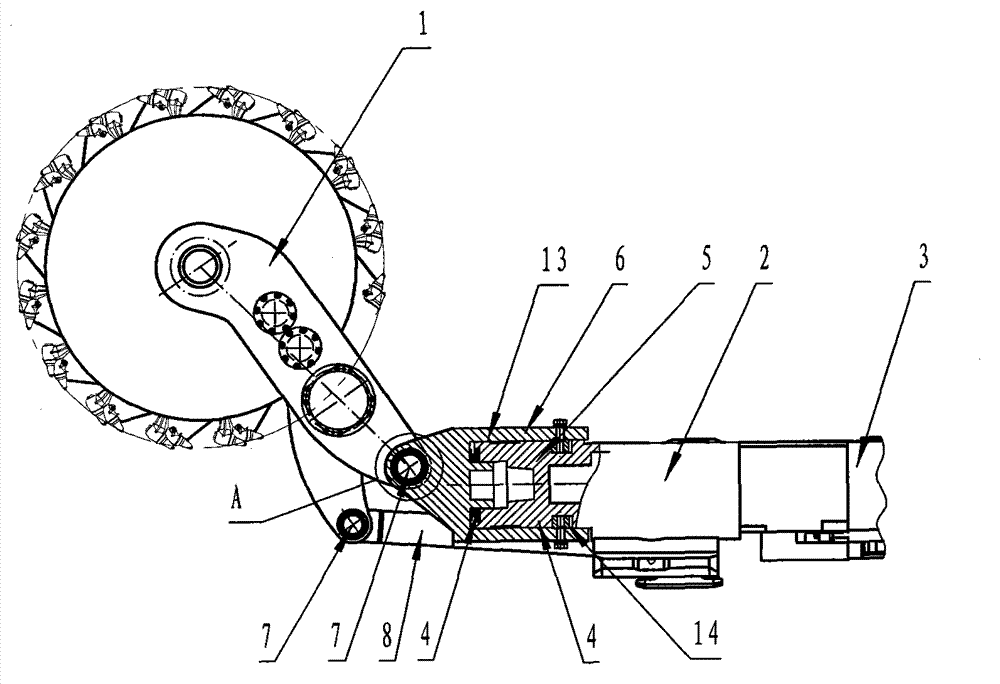

[0044] Such as Figure 3 to Figure 4 As shown, a vibration isolation shearer includes a cutting mechanism 1 and a fuselage 3. The fuselage 3 includes a traction box 2, an electric control unit, a hydraulic system, and a spray cooling system. The gap between the cutting mechanism 1 and the fuselage 3 is A buffer mechanism 13 is provided, the traction box 2 is provided with a guide member 5, the buffer mechanism 13 is provided with a guide sleeve 6 matched with the guide member 5, a buffer 4 is arranged between the guide member 5 and the guide sleeve 6, and the fuselage 3 includes The traveling device, the cutting mechanism 1 is arranged on the buffer mechanism 13, the traveling device drives the buffer mechanism 13 to walk, and the cutting mechanism 1 continuously cuts coal mining.

[0045] The guide sleeve 6 is provided with a backstop 14, and the backstop 14 cooperates with the fuselage 3 to stop back.

[0046] The guide piece 5 is slidably connected with the guide sleeve 6,...

Embodiment 3

[0054] Such as Figure 5 As shown, the buffer 4 adopts hydraulic pressure, and rubber, polyurethane, spring, pneumatic, plastic, nylon and / or elastic corrugated steel can also be used.

[0055] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com