Stand column supporting fabric shade type dryer

A clothes dryer and cloth cover type technology, which is applied in the field of column-supported cloth cover type clothes dryers, can solve the physical injury of the operator, easily touch the cover body part located at the outer edge of the safety plate, and the clothes dryer is placed Instability and other problems, to achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

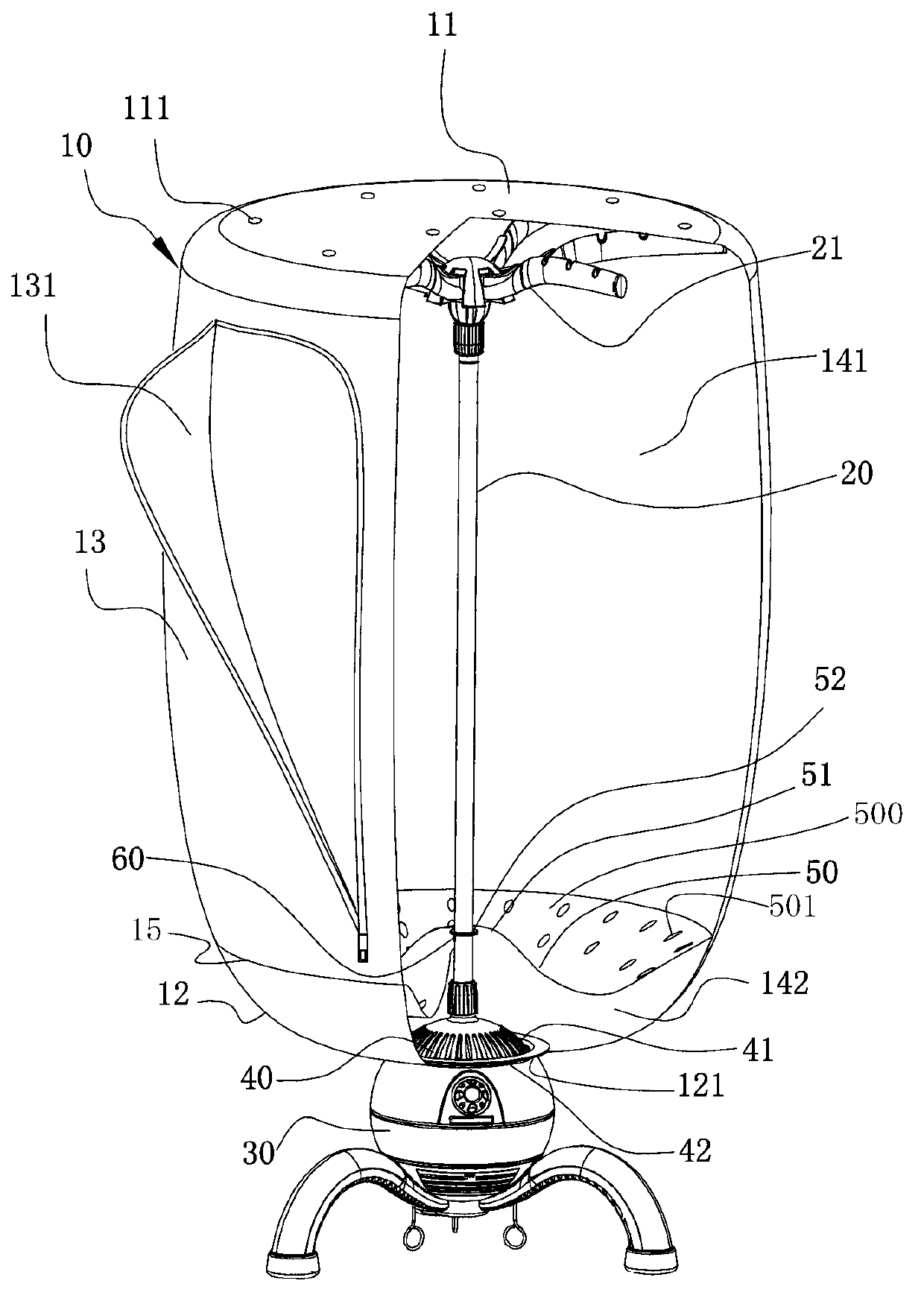

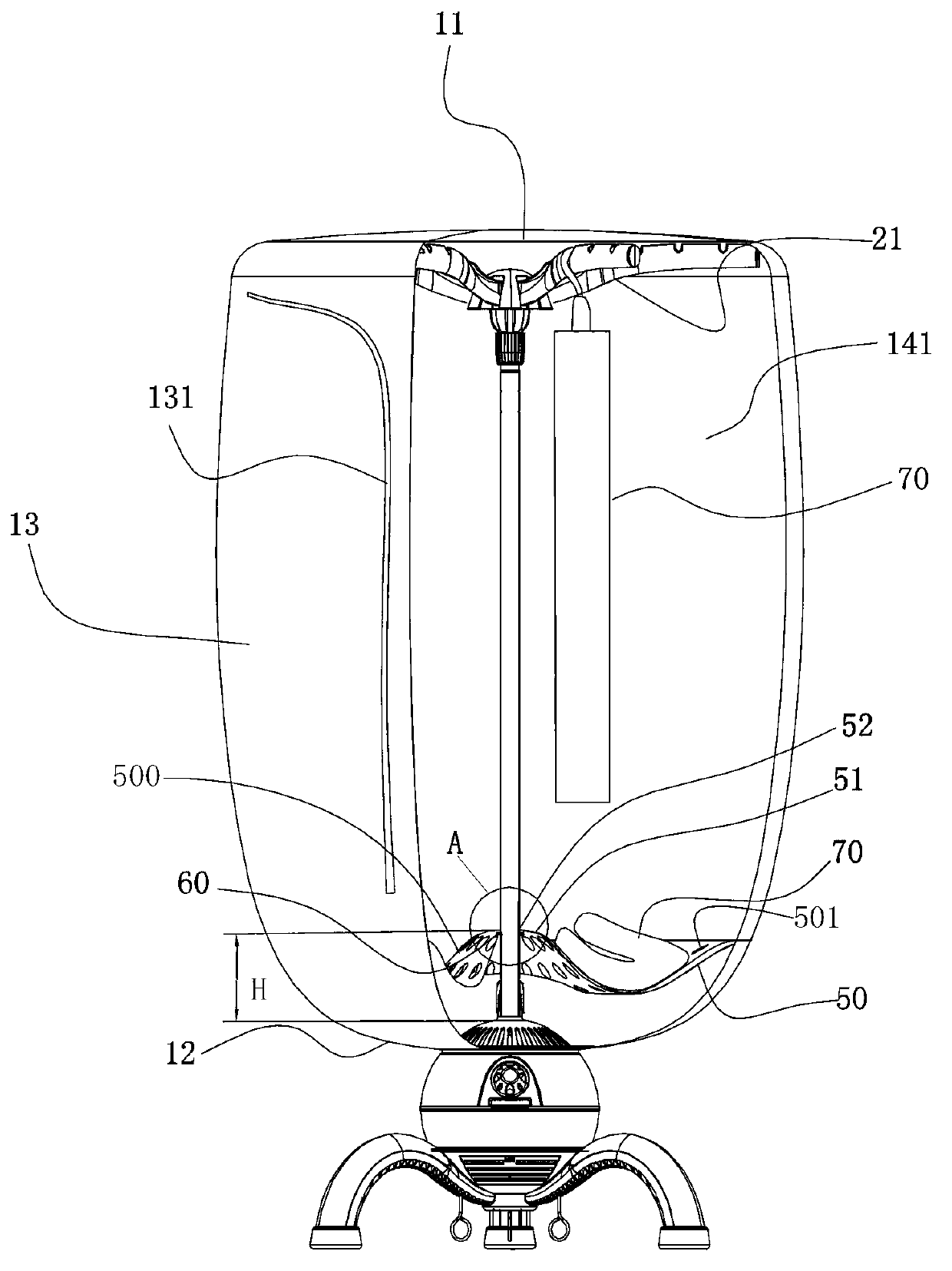

[0045] like figure 1 , Figure 2A , Figure 2B Shown is a column-supported cloth hood dryer in a preferred embodiment of the present invention, the dryer includes a hot air generator 30, and an air outlet shed 40 with multiple air outlets 41 located on the hot air generator 30 , the lower part is supported on the air outlet shed 40, the upper part is connected with the column 20 of the umbrella support frame 21, the cloth cover 10 supported on the umbrella support frame 21, the cloth cover 10 has a top surface 11, a lower bottom surface 12 and a longitudinal peripheral surface 13. The top surface 11 is supported on the umbrella-shaped support frame 21, the longitudinal peripheral surface 13 surrounds the column 20, and the central opening 121 of the lower bottom surface 12 is connected to the air outlet shed 40. Wherein, the bottom of the air outlet shed 40 is connected with the upper casing 42 of the hot wind generator 30, and a circle of grooves is formed at the connection...

no. 2 example

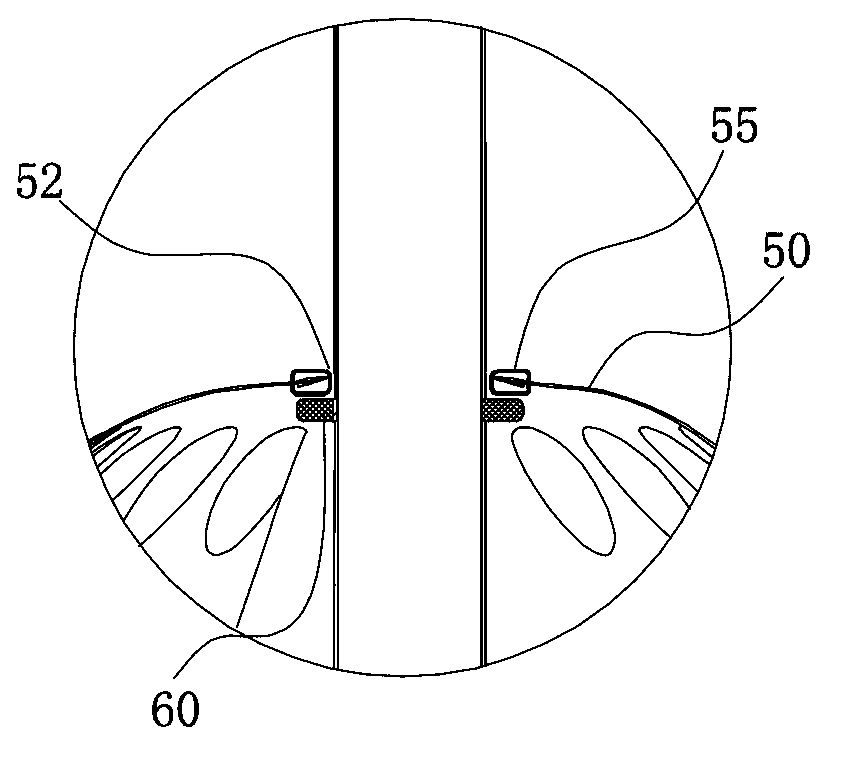

[0058] In order to make the isolation unit 50 of the present invention fold together with the cloth cover 10 into a smaller volume, softer and thinner fabrics are preferably used, so preferably, the aperture of the isolation channel 501 is set larger or the isolation channel 501 is arranged The ground is relatively dense, especially when the isolation unit 50 is only made of a flexible mesh cloth. Such isolating unit 50 is less resistant to tensile deformation on the plane, and its strength cannot be guaranteed. The distance between the clothing and the air outlet 41 will be difficult to control.

[0059] Optionally, as in Figure 4A As shown, the isolation unit 50 is evenly provided with a plurality of flexible anti-pull cloth strips 56 for preventing the isolation unit 50 from being stretched and deformed along the circumferential direction from the through hole 52 to the outer peripheral edge, and is used to prevent the isolation unit 50 from being stretched and deformed. ...

no. 3 example

[0066] like Figure 5A , 5BAs shown, the longitudinal positioning device 60 is provided with a connection portion connected to the middle portion 51 of the isolation unit 50 . Optionally, the connecting portion is a hole 611 arranged at intervals along the periphery of the longitudinal positioning device 60, and the periphery of the through hole 52 of the isolation unit 50 is provided with a hook 511 that can penetrate into the hole 611. After the hook 511 penetrates into the hole 611, the isolation The central part 51 of the unit 50 is fixed on the longitudinal positioning means 60 . Since the hook 511 and the hole 611 are detachably connected, the disassembly and assembly between the two is relatively simple.

[0067] It is worth noting that the connection between the vertical positioning device 60 and the middle part 51 is not limited to the structure of this embodiment, for example, the vertical positioning device 60 may also include a hook fixed on the column 20, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com