Immersion type grooved circulating water cooling plant for wire rods

A circulating water cooling and immersion technology, which is applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of poor cooling effect, heavy equipment cost, uneven cooling, etc., and achieve compact structure and low cost. Low, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

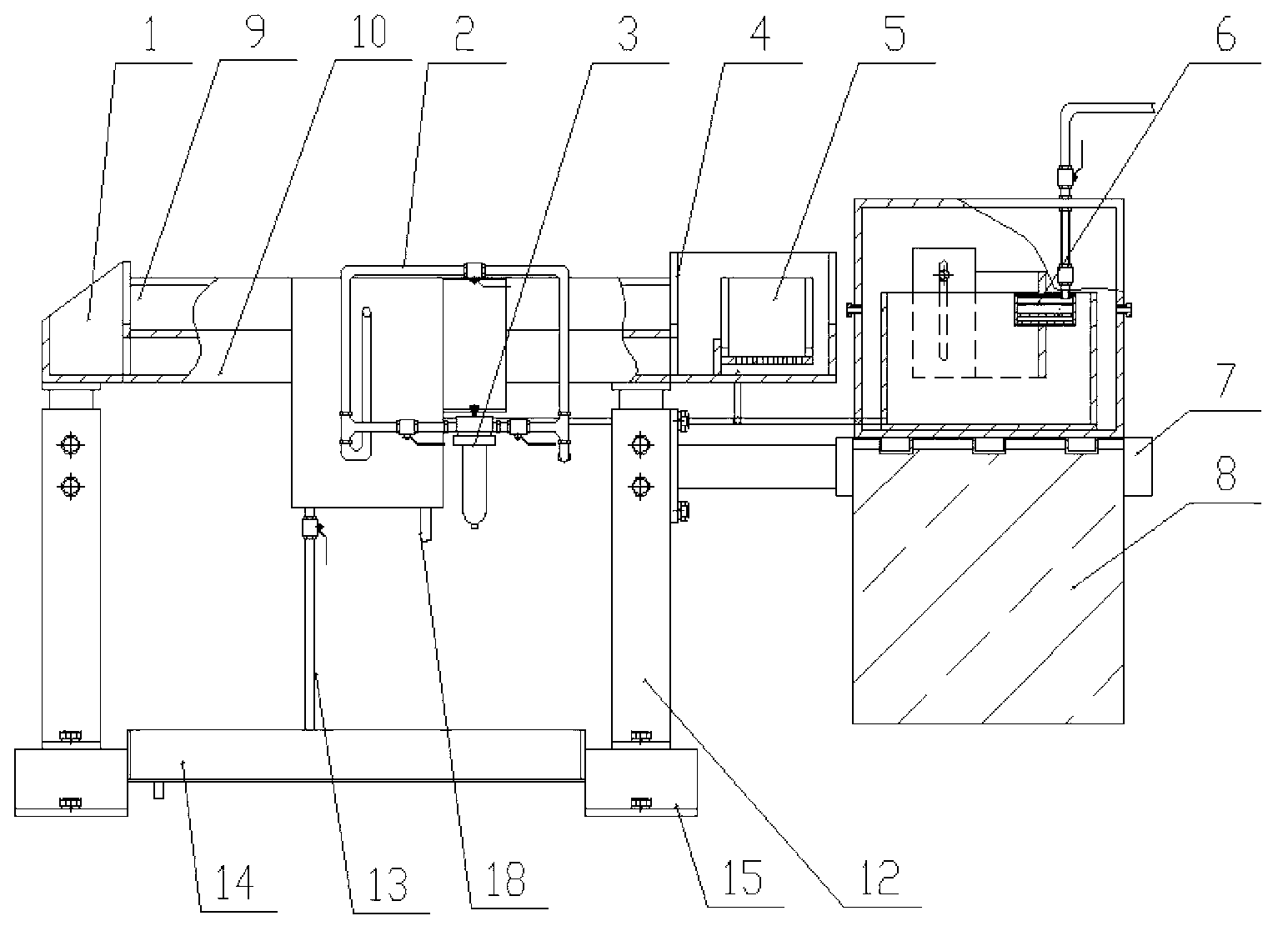

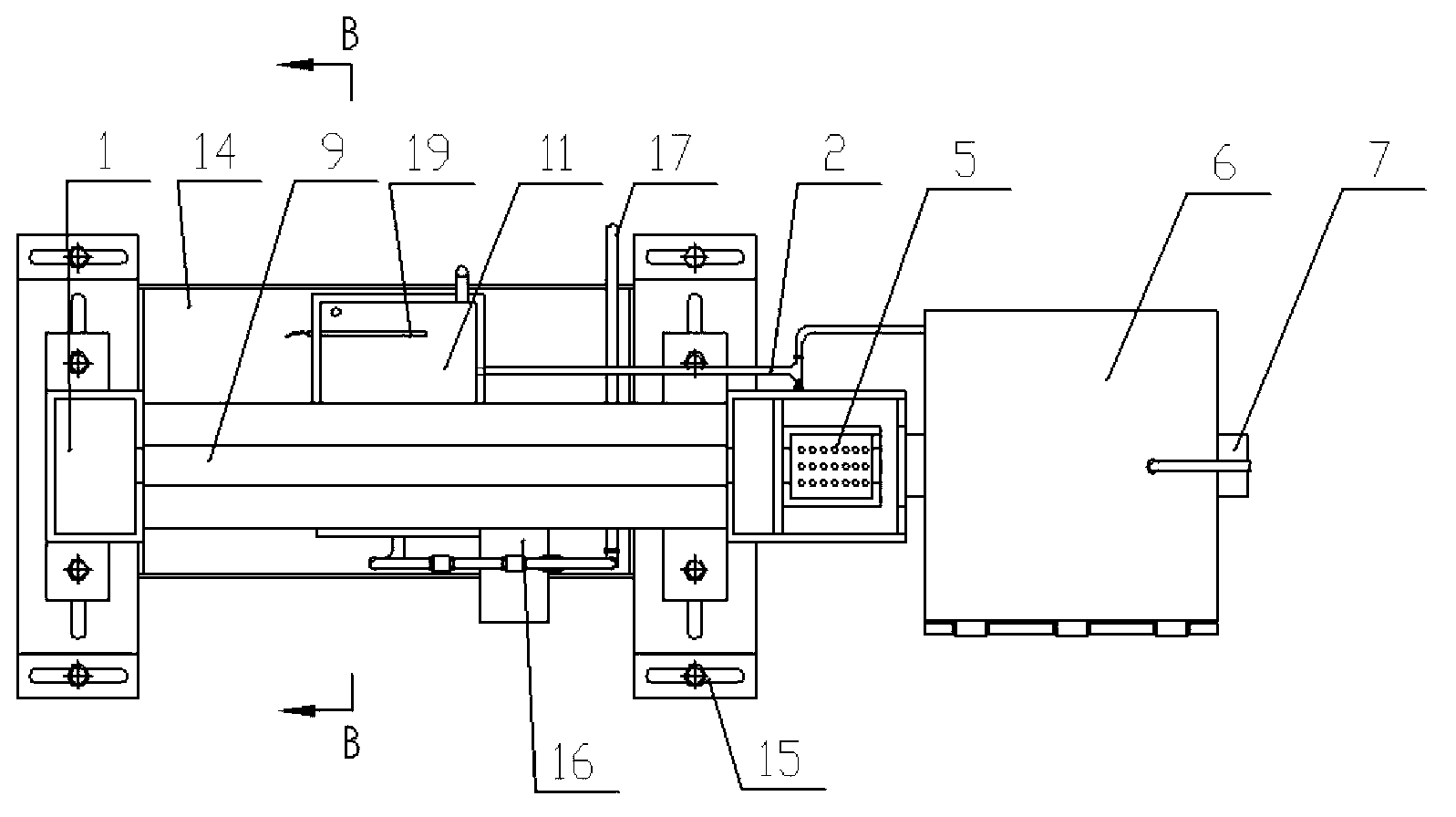

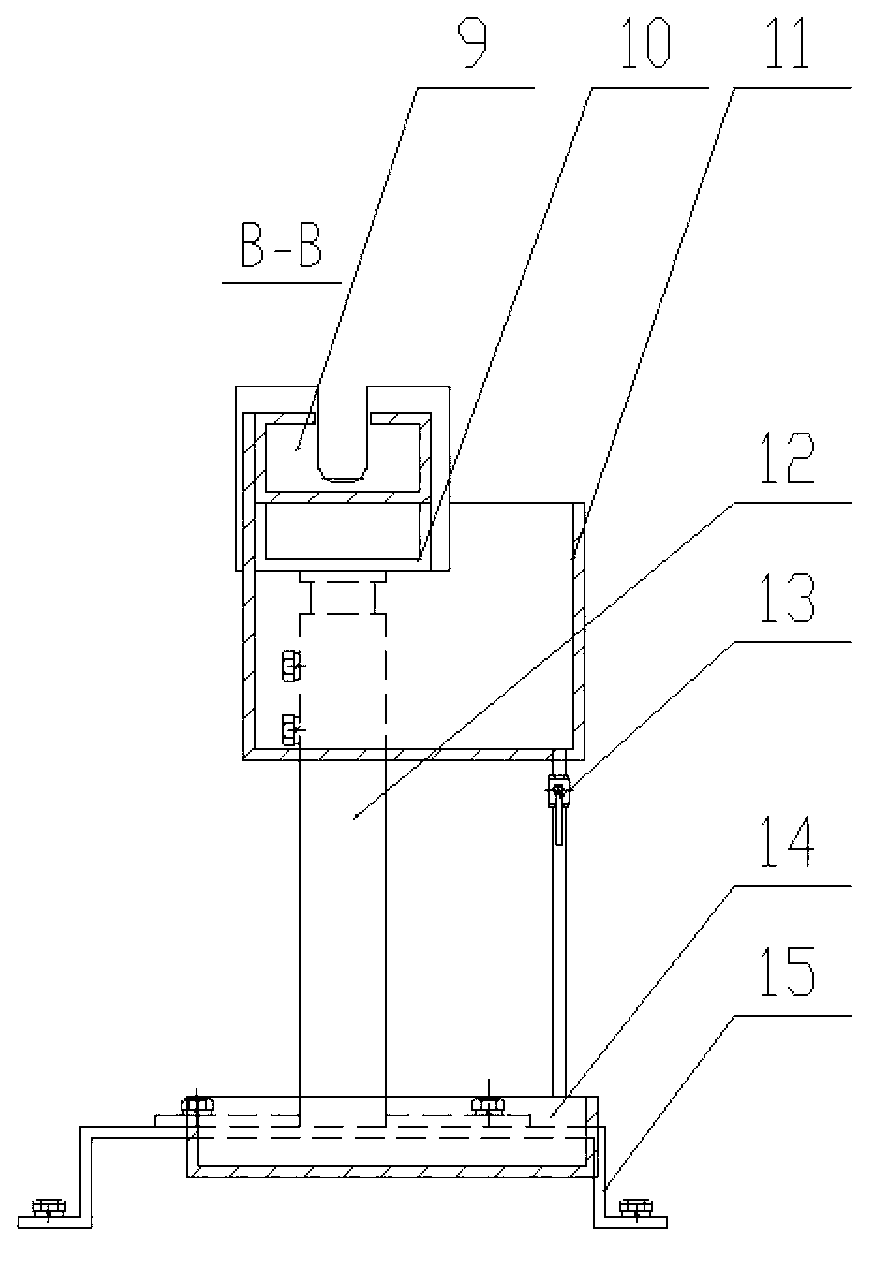

[0013] The present invention is used for the submerged groove type circulating water cooling device of the wire, and the structure is as follows Figure 1-3 As shown, it includes a circulating cooling and drying device, which is arranged on a position adjusting device 12, and the position adjusting device 12 adjusts the height and horizontal position of the cooling and drying device, and the position adjusting device 12 is arranged on a base 15 with a long hole .

[0014] Specifically, the circulating cooling and drying device includes a cooling tank 9 and a water return tank 10 fixed up and down. The first water return sump 1 is fixed at one end of the cooling tank 9 and the return water tank 10 and communicates internally, and the second return water sump 4 is fixed. The other end of the cooling tank 9 and the water return tank 10 are connected internally, the side wall of the water return tank 10 is provided with a water inlet pipe support 16, and the water inlet pipe suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com