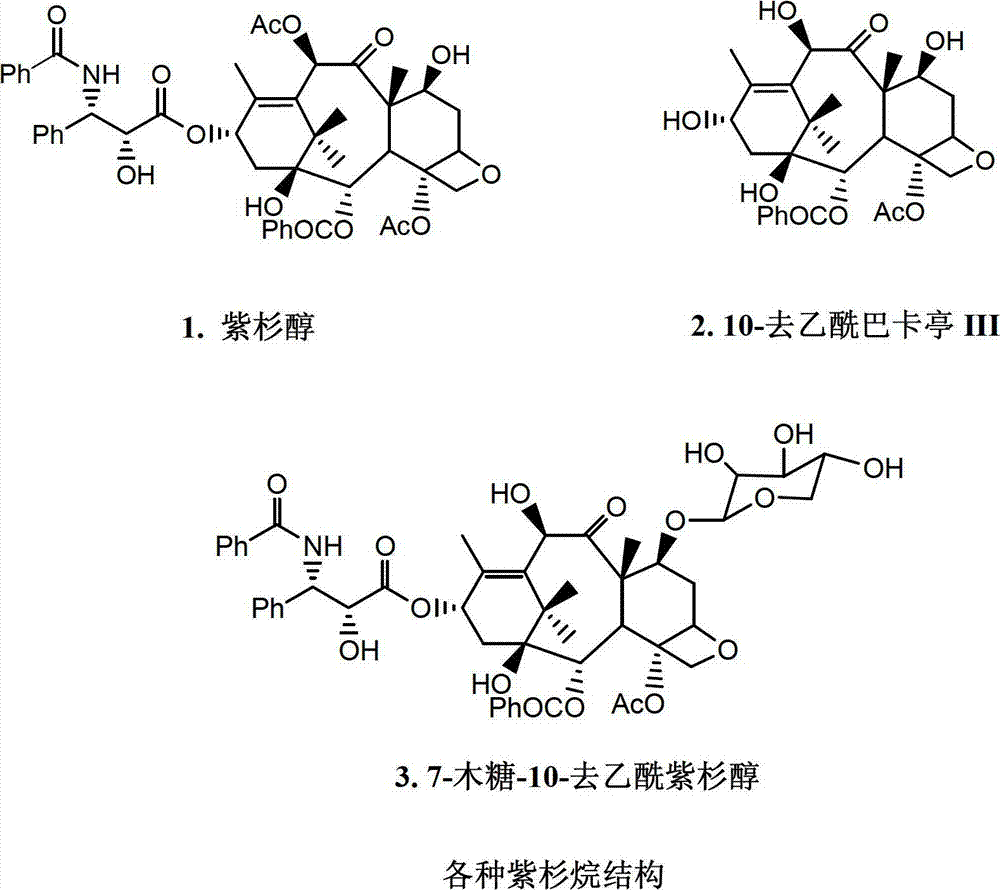

Method for producing 7-xylose-10-deacetyl paclitaxel and special culture medium thereof

A technology for deacetylpaclitaxel and culture medium, which is applied in the field of producing 7-xylose-10-deacetylpaclitaxel, and achieves the effects of short growth cycle, environmental resource protection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

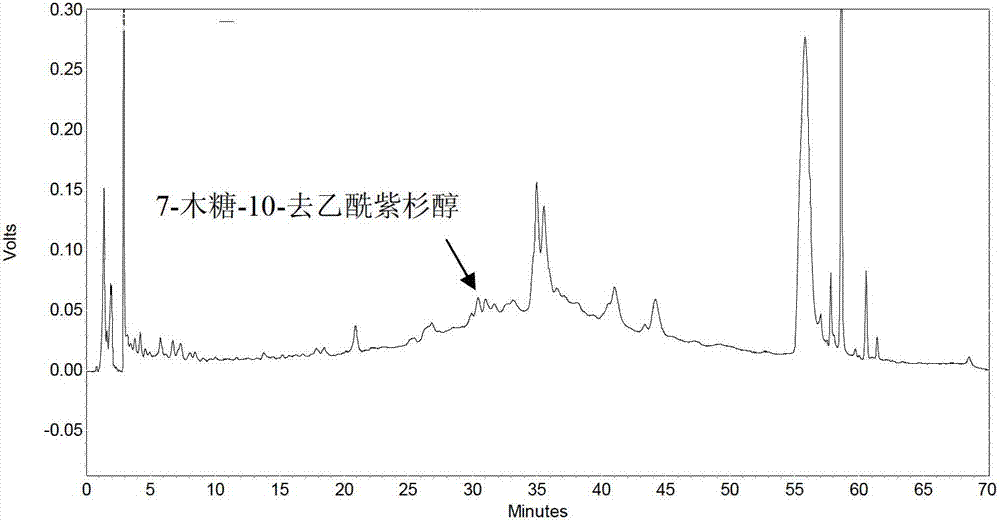

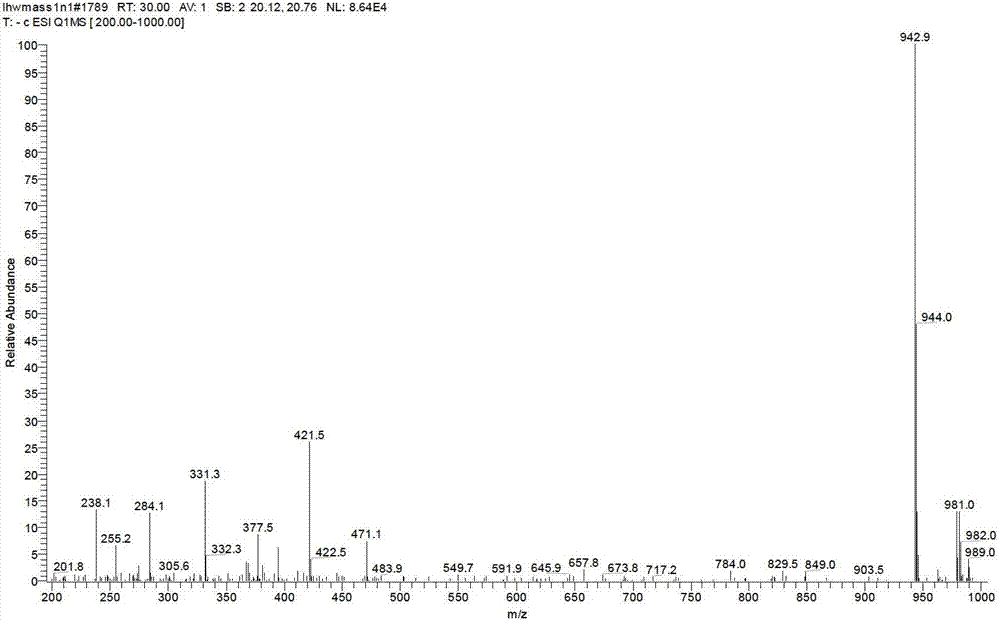

[0023] Example 1: Obtaining 7-xylose-10-deacetylpaclitaxel by culturing the tender stems of Taxus chinensis

[0024] Basic medium: NH 4 NO 3 1300mg, KNO 3 2000mg, KH 2 PO 4 360mg, CaCl 2 2H 2 O 460mg, MgSO 4 ·7H 2 O 380mg, FeSO 4 ·7H 2 O 29 mg, Na 2 -EDTA 38mg, MnSO 4 4H 2 O 2.5 mg, H 3 BO 3 0.7mg, KI 0.9mg, Na 2 MoO 4 2H 2 O 0.03mg, CuSO 4 ·5H 2 O 0.003mg, CoCl 2 ·6H 2 O 0.003mg, Zn.Na-EDTA 17mg, thiamine hydrochloride 0.6mg, nicotinic acid 0.6mg, pyridoxine hydrochloride 0.6mg, glycine 3mg, dilute to 1L with water, pH5.8.

[0025] Callus induction medium: 7 mg of 2,4-D, 50 g of sucrose, and 8 g / L of agar are added to the basic medium.

[0026] Subculture medium: 5 mg of 2,4-D, 50 g of sucrose, and 8 g / L of agar were added to the basic medium.

[0027] The sterilization conditions of the above-mentioned culture medium are all: sterilization at 121° C. for 20 minutes.

[0028] The method of the present invention is used to cultivate Taxus chinensis, ...

Embodiment 2

[0037] Example 2: Obtaining 7-xylose-10-deacetylpaclitaxel by culturing the needles of Taxus yunnanensis

[0038] Basic medium: NH 4NO 3 1200mg, KNO 3 1900mg, KH 2 PO 4 340mg, CaCl 2 2H 2 O 440mg, MgSO 4 ·7H 2 O 370mg, FeSO 4 ·7H 2 O 27.8 mg, Na 2 -EDTA 37.3mg, MnSO 4 4H 2 O 2.23 mg, H 3 BO 3 0.63mg, KI 0.83mg, Na 2 MoO 4 2H 2 O 0.025mg, CuSO 4 ·5H 2 O 0.0025 mg, CoCl 2 ·6H 2 O 0.0025mg, Zn.Na-EDTA 15mg, thiamine hydrochloride 0.5mg, nicotinic acid 0.5mg, pyridoxine hydrochloride 0.5mg, glycine 2mg, dilute to 1L with water, pH5.8.

[0039] Callus induction medium: add 2,4-D 6mg, sucrose 40g, and agar 6g / L on the basis of basic medium.

[0040] Subculture medium: 4 mg of 2,4-D, 40 g of sucrose, and 6 g / L of agar were added to the basic medium.

[0041] The sterilization conditions of the above-mentioned culture medium are all: sterilization at 121° C. for 20 minutes.

[0042] Now use the method of the present invention to cultivate Taxus yunnanensis,...

Embodiment 3

[0051] Example 3: Obtaining 7-xylose-10-deacetylpaclitaxel by culturing the male flowers of Taxus sinensis

[0052] Basic medium: NH 4 NO 3 1100mg, KNO 3 1800mg, KH 2 PO 4 320mg, CaCl 2 2H 2 O 420mg, MgSO 4 ·7H 2 O 350mg, FeSO 4 ·7H 2 O 26 mg, Na 2 - EDTA 36mg, MnSO 4 4H 2 O 2.0 mg, H 3 BO 3 0.5mg, KI 0.7mg, Na 2 MoO 4 2H 2 O 0.02mg, CuSO 4 ·5H 2 O 0.002mg, CoCl 2 ·6H 2 O 0.002mg, Zn.Na-EDTA 12mg, thiamine hydrochloride 0.4mg, nicotinic acid 0.4mg, pyridoxine hydrochloride 0.4mg, glycine 1mg, dilute to 1L with water, pH5.6.

[0053] Callus induction medium: add 2,4-D 6mg, sucrose 20g, and agar 5g / L on the basis of basic medium.

[0054] Subculture medium: 1 mg of 2,4-D, 20 g of sucrose, and 5 g / L of agar were added to the basic medium.

[0055] The sterilization conditions of the above-mentioned culture medium are all: sterilization at 121° C. for 20 minutes.

[0056] Now use the method of the present invention to cultivate Taxus sinensis, and extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com