Waste-utilizing foam concrete and preparation process thereof

A technology of foam concrete and foaming agent, which is applied in the field of building materials, can solve the problems of groundwater resource pollution, large land occupation, etc., and achieve the effects of saving energy and resources, reducing CO2 emissions, and reducing the amount of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

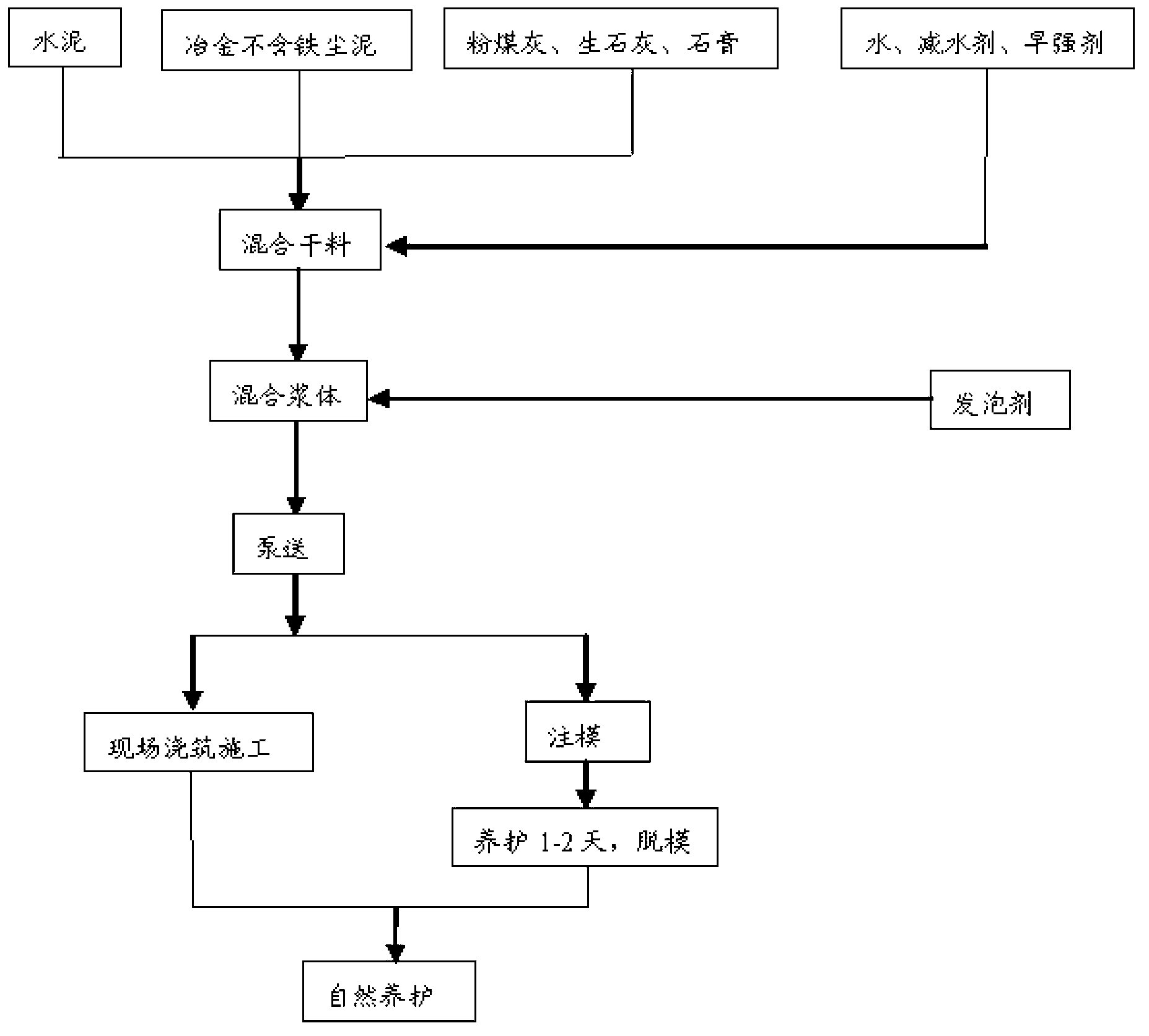

Method used

Image

Examples

Embodiment 1

[0042] (a) Design density is 500kg / m 3 The total amount of dry material in each cubic foam concrete is 417kg, including 50wt% cement, 10wt% metallurgical iron-free dust, 28wt% fly ash, 8wt% quicklime, 2wt% gypsum, and 1.2wt% water reducer , 0.8wt% early strength agent, mix cement, metallurgical iron-free dust, fly ash, quicklime, and gypsum, and stir evenly for 2-3 minutes;

[0043] (b) Weigh water according to the water-cement ratio of 0.40, take a small amount of water to dilute 1.14kg of foaming agent (corresponding to 1m 3 Foam concrete, dilute 20-30 times with water); then add the remaining water, water reducer, and early strength agent to the dry material obtained in step a, and stir evenly for 2-3 minutes;

[0044] (c) Foam the foaming agent obtained in step b using a cement foaming machine, then blow it into the pre-mixed cement slurry, and stir evenly for 3-4 minutes;

[0045] (d) Import the prepared slurry into the trough, and send it into the mold with a delivery ...

Embodiment 2

[0048] (a) For foam concrete with a design density of 800kg / m3, the total amount of dry material per cubic foam concrete is 667kg, of which 50wt% cement, 10wt% metallurgical iron-free dust, 28wt% fly ash, 8wt% quicklime, 2wt% % gypsum, 1.2wt% water reducer, 0.8wt% early strength agent, mix cement, metallurgical iron-free dust, fly ash, quicklime, and gypsum, and stir evenly for 2-3 minutes;

[0049] (b) Weigh water according to the water-cement ratio of 0.40, take a small amount of water to dilute 0.87kg foaming agent (corresponding to 1m 3 Foam concrete, dilute 20-30 times with water); then add the remaining water, water reducer, and early strength agent to the dry material obtained in step a, and stir evenly for 2-3 minutes;

[0050] (c) Foam the foaming agent obtained in step b using a cement foaming machine, then blow it into the pre-mixed cement slurry, and stir evenly for 3-4 minutes;

[0051] (d) Import the prepared slurry into the trough, and send it into the mold wit...

Embodiment 3

[0054] (a) For foam concrete with a design bulk density of 500kg / m3, the total amount of dry material per cubic foam concrete is 417kg, of which 50wt% cement, 20wt% metallurgical iron-free dust, 20wt% fly ash, 6wt% quicklime, 2wt% % gypsum, 1.2wt% water reducer, 0.8wt% early strength agent, mix cement, metallurgical iron-free dust, fly ash, quicklime, and gypsum, and stir evenly for 2-3 minutes;

[0055] (b) Weigh water according to the water-cement ratio of 0.40, take a small amount of water to dilute 1.14kg of foaming agent (corresponding to 1m 3 Foam concrete, dilute 20-30 times with water); then add the remaining water, water reducer, and early strength agent to the dry material obtained in step a, and stir evenly for 2-3 minutes;

[0056] (c) Foam the foaming agent obtained in step b using a cement foaming machine, then blow it into the pre-mixed cement slurry, and stir evenly for 3-4 minutes;

[0057] (d) Import the prepared slurry into the trough, and send it into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com