Fabrication method of graphene nanobelt with visible-light response

A graphene nanobelt, visible light technology, applied in the direction of graphene, nanotechnology for materials and surface science, nanocarbon, etc., to achieve the effect of simple equipment, favorable for industrialization promotion, and good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

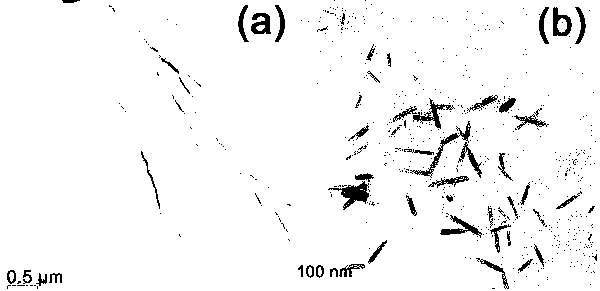

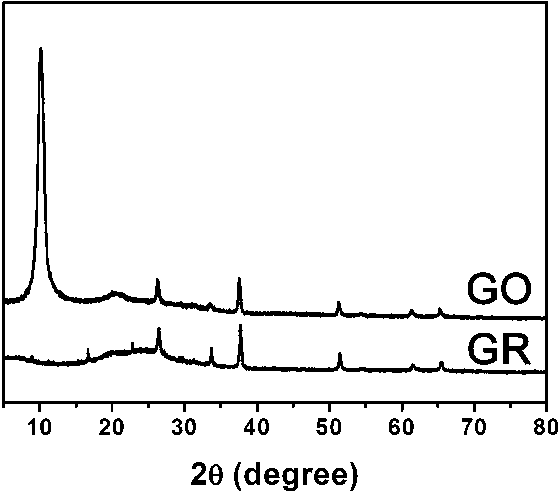

[0019] Example 1: 5ml of graphene oxide (GO, 2.1mg / ml) was measured by a measuring cylinder, dispersed in 40ml of ultrapure water, ultrasonically dispersed for 1 hour, and then evaporated to dryness at 60°C. Then, the evaporated GO flakes were transferred to a vacuum tube furnace and vacuum reduced at 300 °C for 3 h. The graphene obtained after reduction was again dispersed in 20ml ultrapure water, ultrasonically dispersed for 10min, 30min, 1h, 2h, 4h, 8h, and washed 3 times. Finally, it was dispersed in 5ml ultrapure water to obtain graphene nanoribbons, marked as GR.

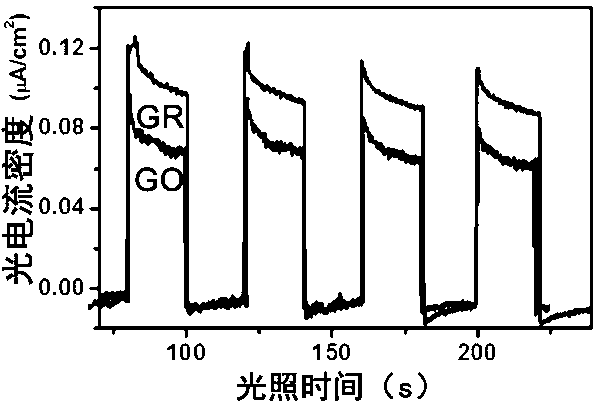

[0020] The photocurrent test and evaluation method provided by the present invention is as follows: what we adopted is the test system of three standard electrodes, with 0.5 M sodium sulfate as electrolyte, the prepared samples are dispersed on conductive glass (the area of the samples is 0.5 cm -2 ), as the working electrode; platinum electrode as the contrast electrode; saturated Ag / AgCl as the reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com