Method for regulating structure of nanosphere convex plane array type SERS (Surface Enhanced Raman Scattering) substrate

A planar array, nanosphere technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of small substrate area, difference, difficult high-throughput preparation of high-quality SERS substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

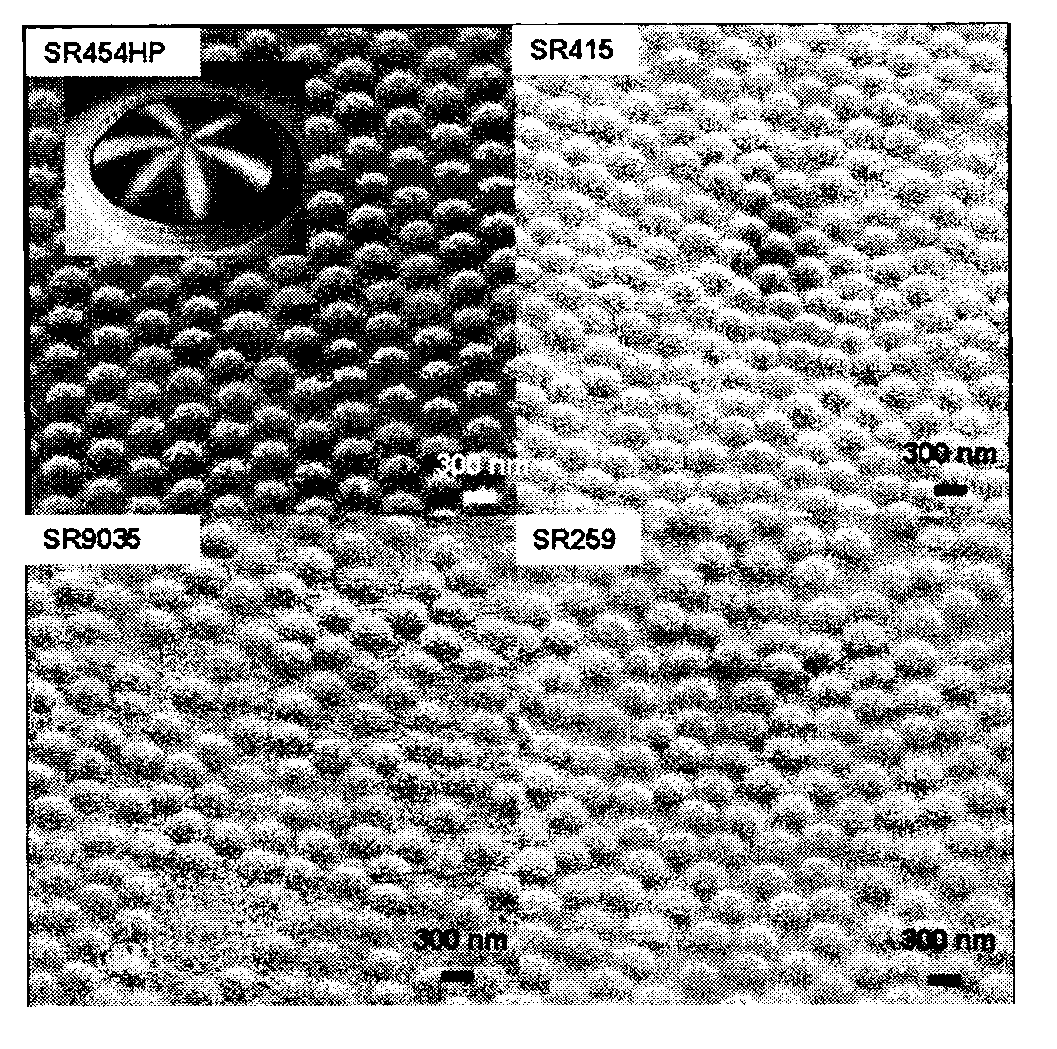

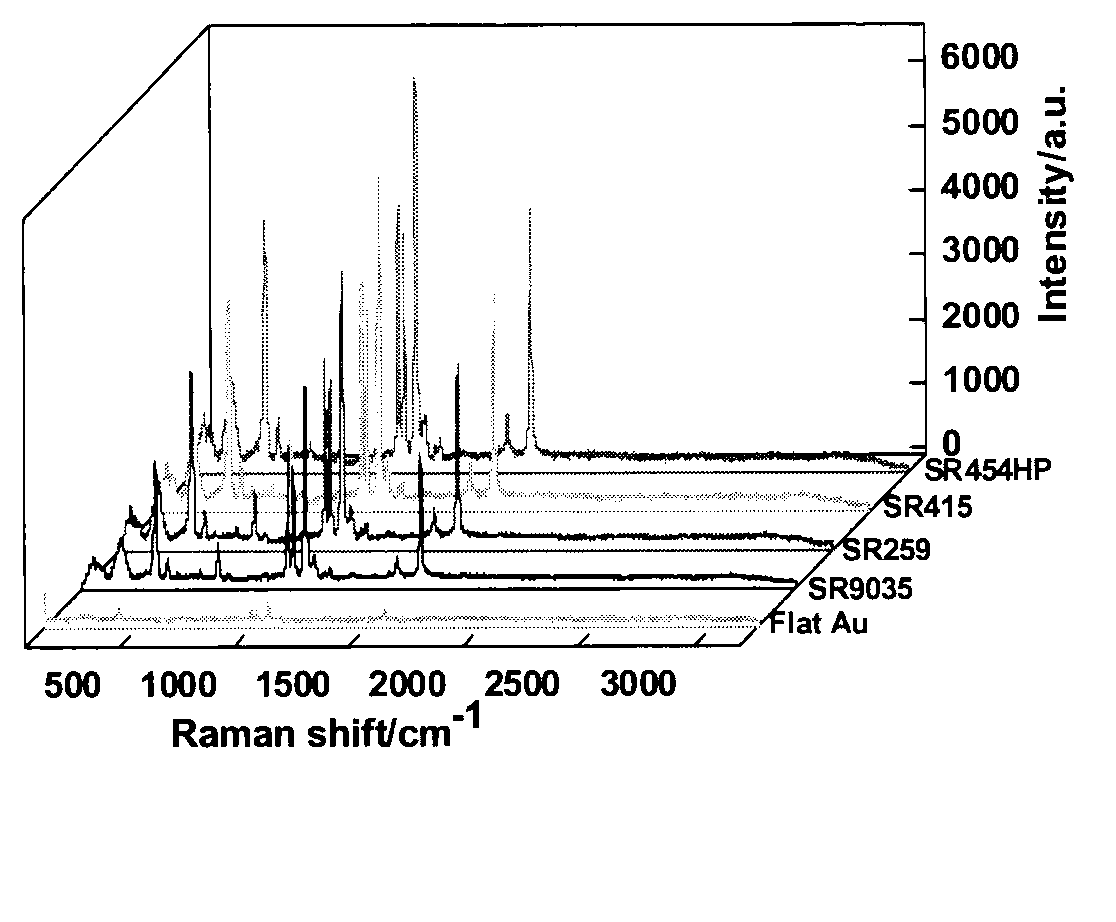

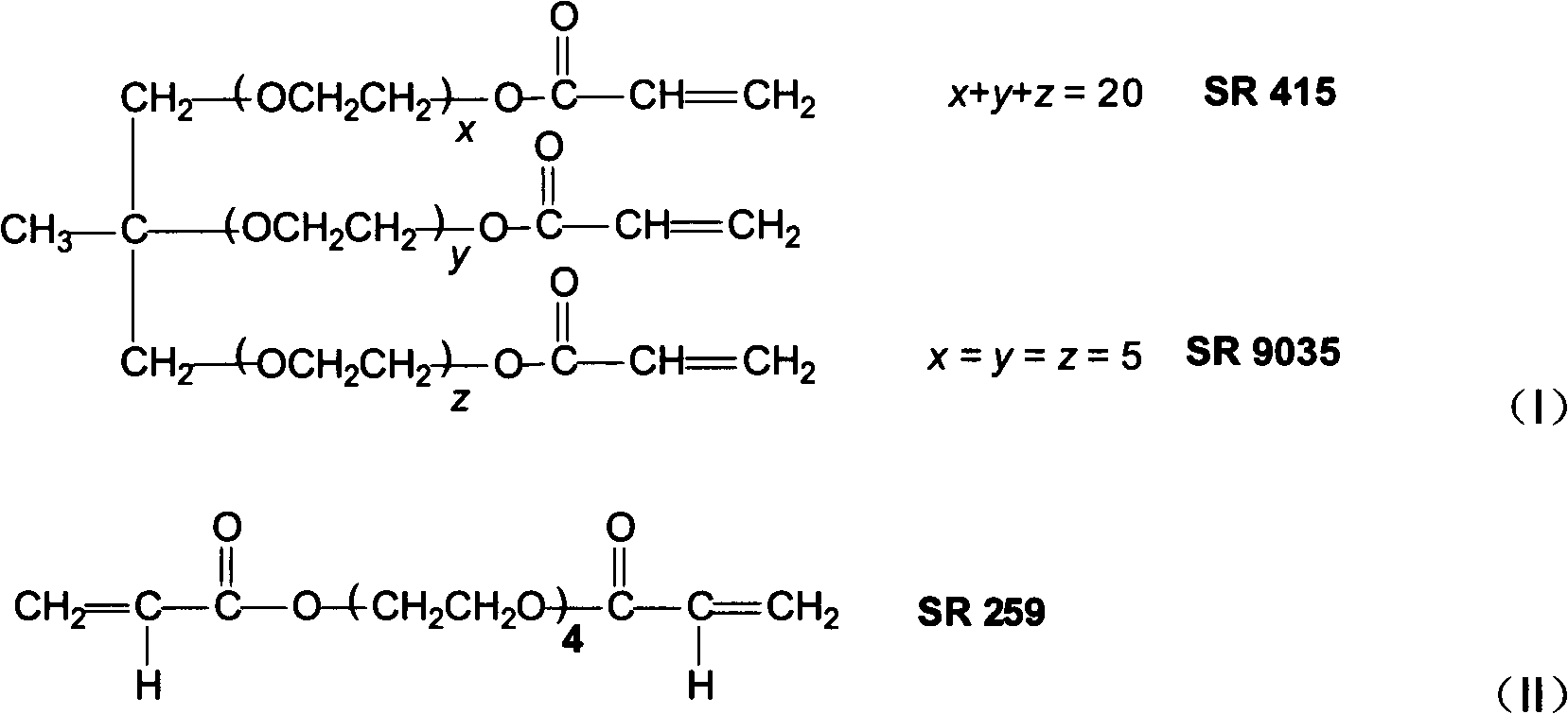

[0016] Example 1 Preparation and Structural Characterization of Nanosphere Convex Plane Array SERS Substrate

[0017] Silica microspheres with a diameter of 300nm and the polymerizable monomer SR454HP were formulated into a solid-liquid suspension mixture with a volume ratio of 1:4, and the silica-SR454HP solid-liquid suspension mixture was uniformly coated on the diameter of On the surface of a 15.24 cm single crystal silicon wafer, pulse UV light for 12 seconds to initiate in-situ polymerization and solidification of the silica-SR454HP solid-liquid suspension mixture, and then use an electron beam evaporation gold plating equipment to coat a 18nm gold film to prepare nanospheres Convex planar array type SERS substrate. attached figure 1 It is a field emission scanning electron microscope image of a nanosphere convex plane array type SERS substrate, and an electronic digital photo of the obtained SERS substrate is inserted in the figure. The nano-silica microspheres are wra...

Embodiment 2

[0018] Example 2 Preparation and Structural Characterization of Nanosphere Convex Plane Array SERS Substrate

[0019] Silica microspheres with a diameter of 300nm and polymerizable monomer SR415 were formulated into a solid-liquid suspension mixture with a volume ratio of 1:4, and the silica-SR415 solid-liquid suspension mixture was evenly coated on the surface with a diameter of On the surface of a 15.24 cm single crystal silicon wafer, pulse UV light for 12 seconds to initiate in-situ polymerization and solidification of the silica-SR415 solid-liquid suspension mixture, and then use an electron beam evaporation gold plating equipment to coat a 18nm gold film to prepare nanospheres Convex planar array type SERS substrate. From attached figure 1 It can be seen that the arrangement of nano-spherical protrusions is good, and the arrangement density of nano-spherical protrusions on the substrate surface is 6.86×10 8 piece / cm 2 .

Embodiment 3

[0020] Example 3 Preparation and Structural Characterization of Nanosphere Convex Plane Array SERS Substrate

[0021] Silica microspheres with a diameter of 300nm and polymerizable monomer SR9035 were formulated into a solid-liquid suspension mixture with a volume ratio of 1:4, and the silica-SR9035 solid-liquid suspension mixture was uniformly coated on the surface with a diameter of On the surface of a 15.24 cm single crystal silicon wafer, pulse UV light for 12 seconds to initiate in-situ polymerization and solidification of the silica-SR9035 solid-liquid suspension mixture, and then use an electron beam evaporation gold plating equipment to coat a 18nm gold film to prepare nanospheres Convex planar array type SERS substrate. From attached figure 1 It can be seen that the arrangement of nano-spherical protrusions is good, and the arrangement density of nano-spherical protrusions on the substrate surface is 4.52×10 8 piece / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com