Thermal shrink film packaging machine for drug package box

A heat-shrinkable film and packaging machine technology, which is applied in the directions of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problems of complex structure and high manufacturing cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

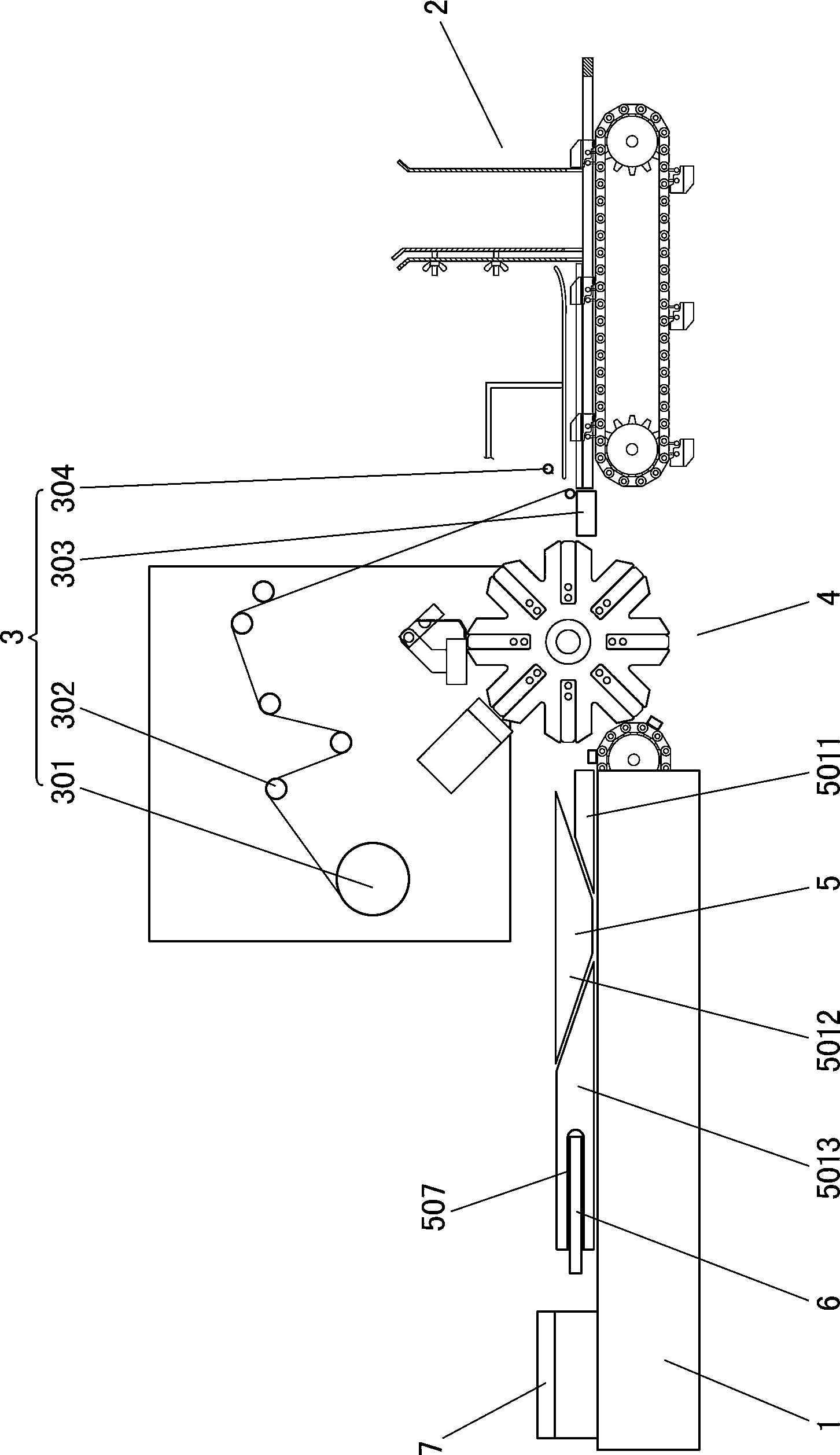

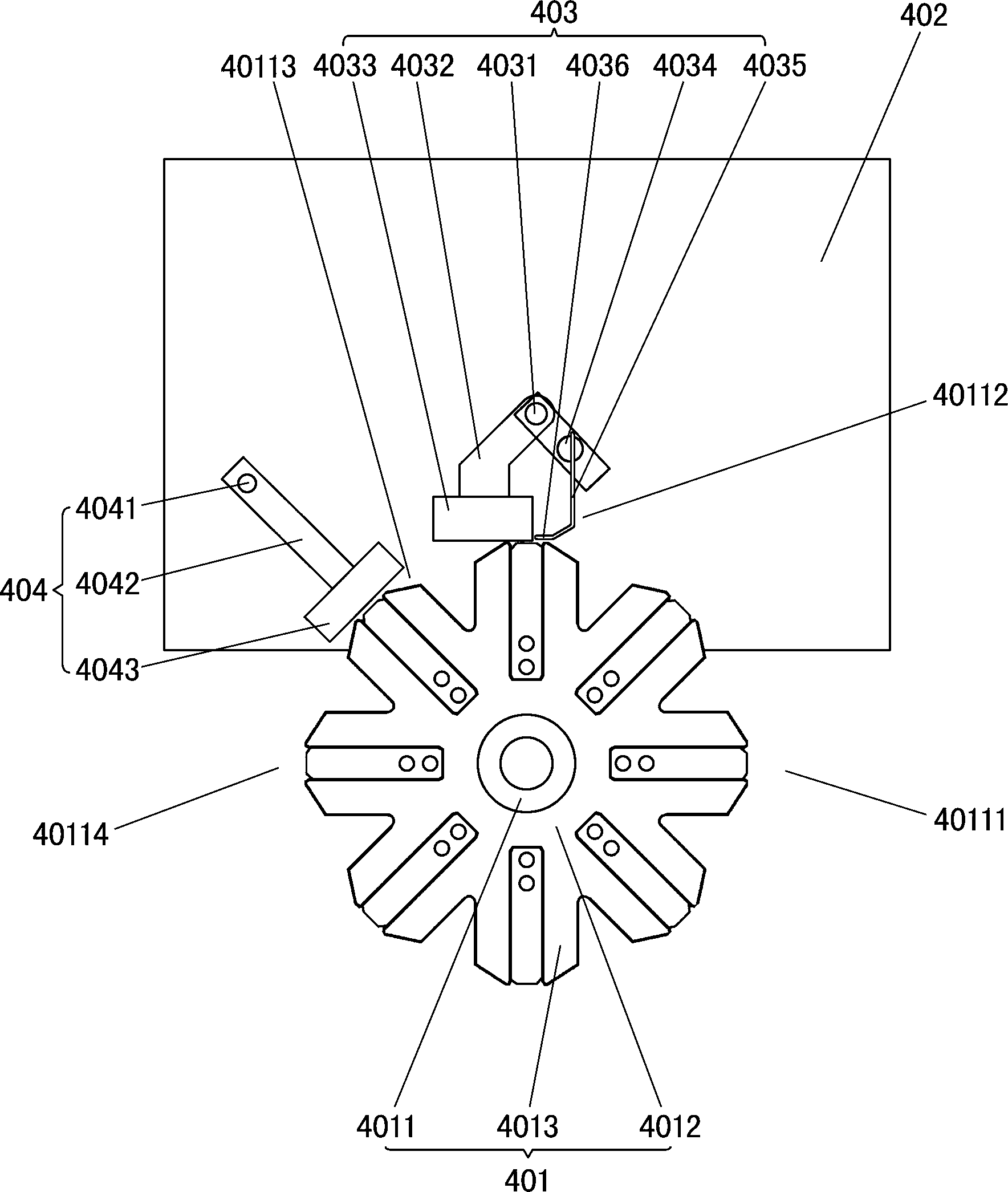

[0025] like figure 1 As shown, this heat shrinkable film packaging machine for pharmaceutical packaging boxes includes a box feeding mechanism 2, a film rolling mechanism 3, a hemming sealing mechanism 4, and a film tube double-end folding mechanism 5, which are sequentially arranged on the frame 1. , film cylinder double-end heat-sealing mechanism 6 and box body surface heat-sealing mechanism 7.

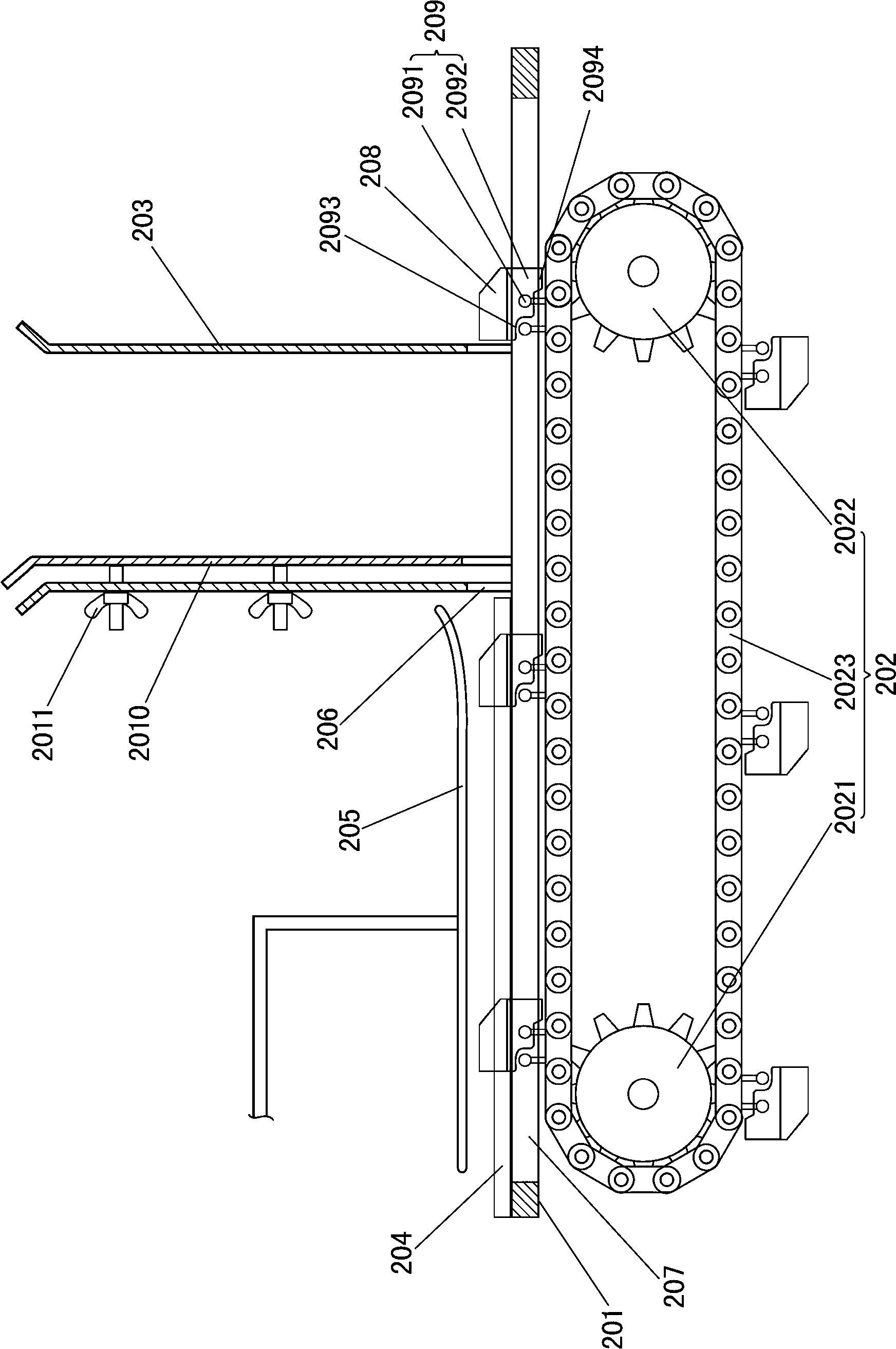

[0026] like figure 2 As shown, the box supply mechanism 2 includes a box supply platform 201, a first conveying mechanism 202, a box supply groove 203, a first guide groove 204 and a limit bezel 205; the box supply platform 201 and the first conveying mechanism 202 are arranged on the frame 1 Above, the first conveying mechanism 202 is below the box feeding platform 201; the first conveying mechanism 202 includes a first driving sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com