Expanded polytetrafluoroethylene-based thermal insulation moisture permeable garment material and preparation method thereof

A polytetrafluoroethylene and bulking technology, applied in the field of textile fabrics, can solve the problems of general thermal insulation, skin itching allergy, poor thermal insulation effect, etc. effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

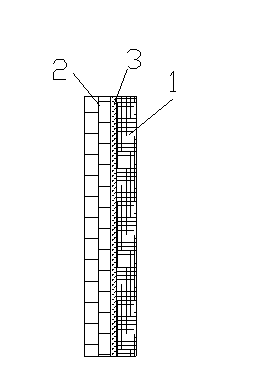

[0048] Embodiment 1: A thermal insulation and moisture-permeable clothing fabric based on expanded polytetrafluoroethylene, comprising: a fabric layer 1, a microporous film layer 2 of expanded polytetrafluoroethylene, an adhesive layer, and the expanded polytetrafluoroethylene One surface of the vinyl microporous film layer 2 is connected with a fabric layer 1 through an adhesive layer, the fabric layer 1 is a textile fabric layer, and the adhesive layer is a chemical adhesive layer 3 .

Embodiment 2

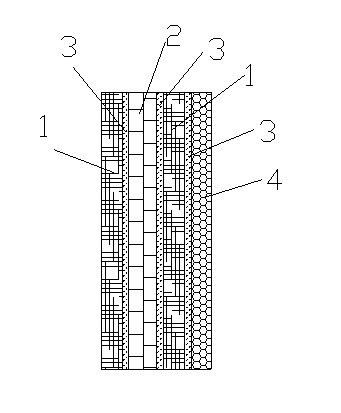

[0049] Embodiment 2: A thermal insulation and moisture-permeable clothing fabric based on expanded polytetrafluoroethylene, comprising: a fabric layer 1, a microporous film layer 2 of expanded polytetrafluoroethylene, an adhesive layer, and the expanded polytetrafluoroethylene Both sides of the vinyl microporous film layer 2 are connected with a fabric layer 1 through an adhesive layer, the fabric layer 1 is a functional fabric layer, and the adhesive layer is a chemical adhesive layer 3 .

Embodiment 3

[0050] Embodiment 3: A thermal insulation and moisture-permeable clothing fabric based on expanded polytetrafluoroethylene, comprising: a fabric layer 1, a microporous film layer 2 of expanded polytetrafluoroethylene, an adhesive layer, and the expanded polytetrafluoroethylene Both sides of the vinyl microporous film layer 2 are connected with a textile fabric layer through an adhesive layer, and the surface of one of the fabric layers 1 is connected with a functional protective fabric layer 4 through an adhesive layer, and the adhesive layer is a chemical adhesive layer. 3.

[0051] The preparation method of the thermal insulation and moisture permeable clothing fabric based on expanded polytetrafluoroethylene in the above 1-3 embodiment comprises the following steps:

[0052] 1) The expanded polytetrafluoroethylene microporous film layer, the fabric layer 1 and the chemical adhesive are prepared for the pre-production process;

[0053] 2) Applying a chemical adhesive to one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com