Preparation method for monodisperse gold nanoparticle and assembly thereof

A gold nanoparticle and nanoparticle technology, which is applied in the field of preparation of noble metal nanoparticles, can solve the problems of low aggregation degree and pore density, and achieve the effects of low cost, simple process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the monodisperse gold nanoparticle and assembly thereof of the present invention, its preferred embodiment comprises:

[0016] First, gold nanoparticles were prepared by reflux method: 82.4mgHAuCl 4 4H 2 O mixed with 5.5ml oleylamine with a mass concentration of 80% and 50ml cyclohexane, stirred at room temperature and passed argon for more than 30min, then rapidly raised to 90°C and kept at this temperature for 10h, then gradually cooled to room temperature , and then use ethanol to wash off the unreacted solvent and by-products in the reaction, centrifuge to obtain gold nanoparticles, and disperse the obtained gold nanoparticles into 2ml of cyclohexane;

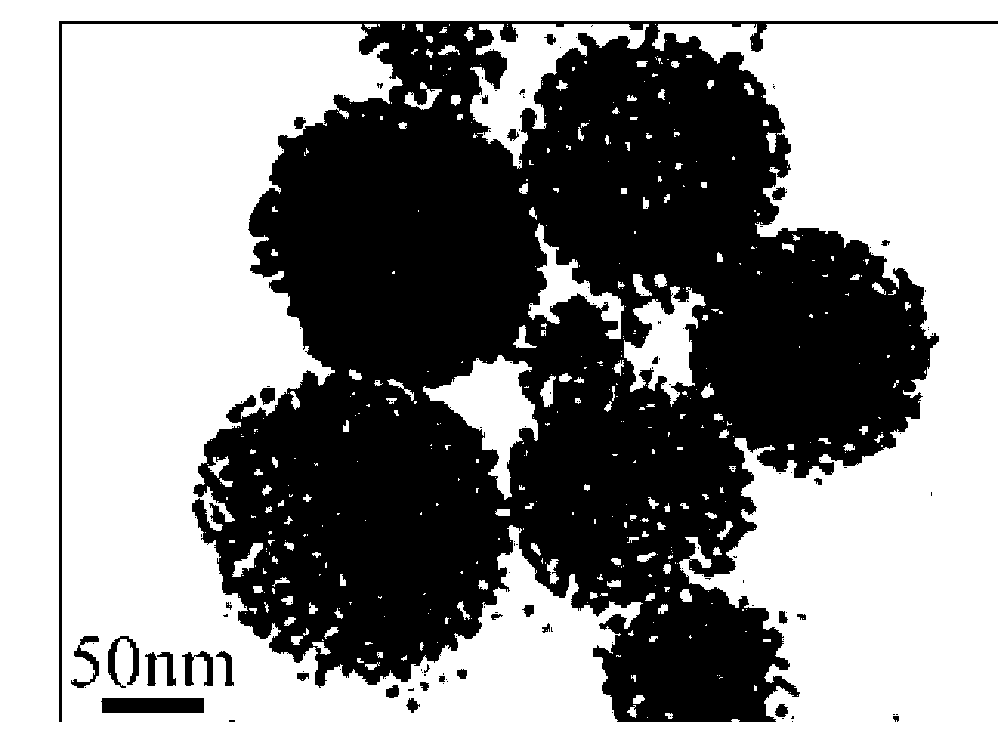

[0017] Then, the porous gold nanoparticle aggregates were prepared by the oil-water two-phase microemulsion method and the process of slowly volatilizing the organic phase.

[0018] The preparation of the gold nanoparticle aggregates comprises steps:

[0019] First prepare the aqueous sol...

specific Embodiment

[0024] First, oleylamine-protected gold nanoparticles were prepared, and then porous gold nanoparticle aggregates were prepared through the process of oil-water two-phase microemulsion and slow volatilization of the organic phase. The concrete operation steps of this preparation method are as follows:

[0025] Preparation of gold nanoparticles:

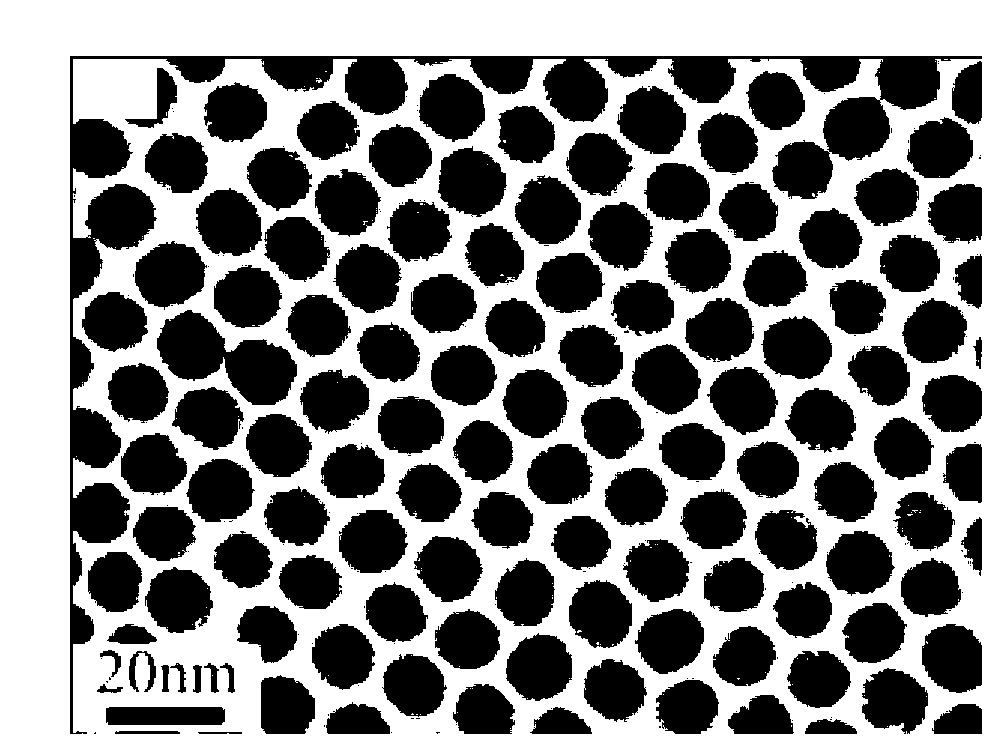

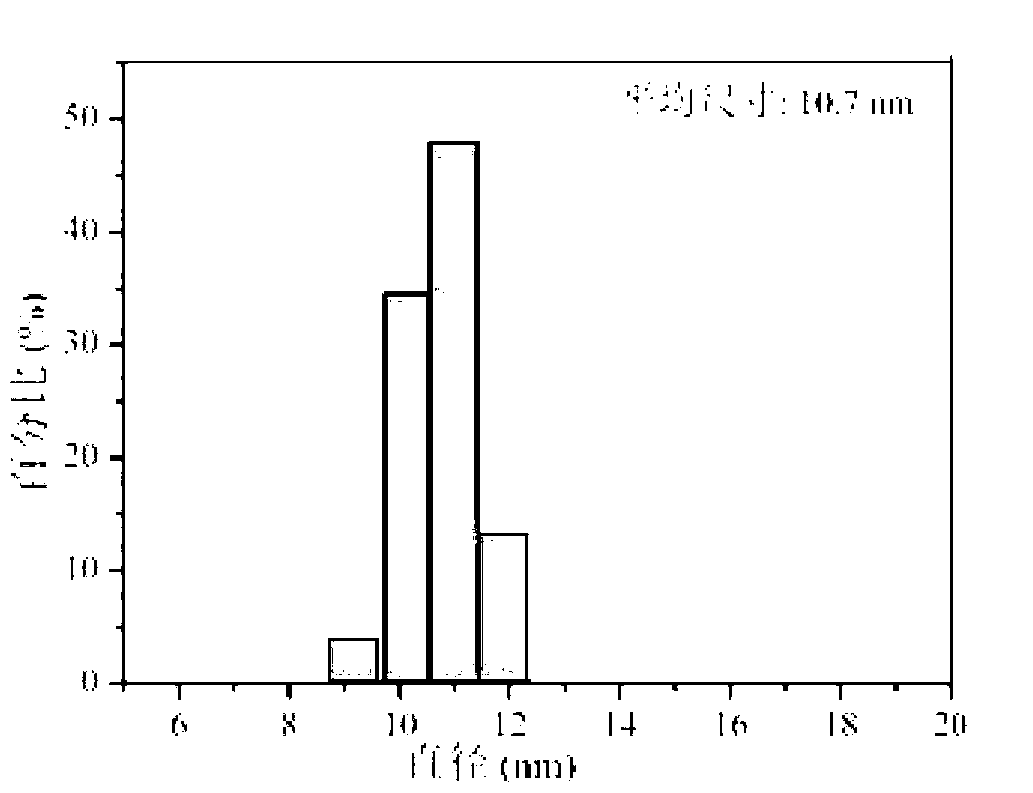

[0026] Preparation of gold nanoparticles (about 10.7nm in size) by reflux method: 82.4mg (0.2mmol) HAuCl 4 4H 2 O, 5.5ml (14mmol) of oleylamine (tech.80%, ACROS) and 50ml of cyclohexane were mixed and poured into a 100ml three-necked flask. The system was stirred at room temperature and passed through argon for about 30 min to completely remove the air in the reaction system, then the temperature was rapidly raised to 90° C. and maintained at this temperature for 10 h. After stopping the reaction, the system was gradually cooled to room temperature, the unreacted solvent and by-products in the reaction were washed away with ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com