Cylinder part cleaning machine

A washing machine and parts technology, applied in the direction of dryers, conveyor objects, cleaning methods and appliances, etc., can solve problems such as high labor intensity, dead cleaning angles, inadequate cleaning, etc., and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

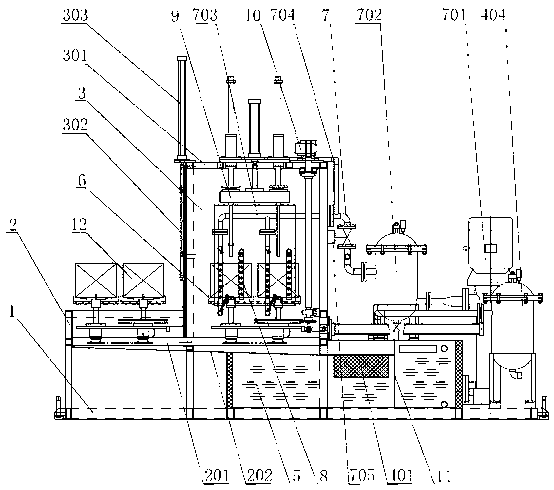

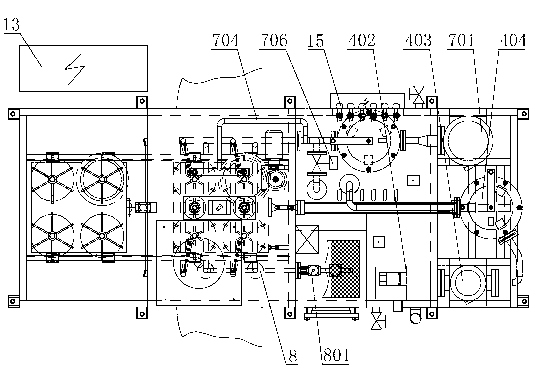

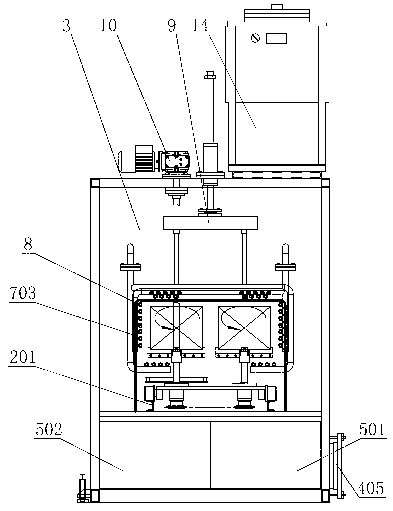

[0035] See figure 1 , figure 2 , image 3 , the present invention comprises frame 1 and electrical control cabinet 13, and horizontally on frame 1, workpiece station 2, cleaning room 3, water treatment system 4 are arranged in sequence; the bottom of cleaning room 3 is provided with water tank 5, and water tank 5 extends to water treatment System 4, water tank 5 includes sewage tank 501 and clean water tank 502, electric heating tube 15 is housed in clean water tank 502, track 201 is arranged on workpiece station 2, track 201 extends to cleaning room 3 and is fixedly connected with the inner wall of cleaning room 3, track The deflector 202 is arranged below the 201, and the deflector 202 extends out of the cleaning chamber 3, and is fixedly connected with the support plate 11 in the sewage tank 501; it also includes a transport vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com