Dropped bottom intermediate air knife double-turning plate quick color changing spraying room

A rapid color change and spray booth technology, applied in the direction of spraying devices, coatings, and devices for coating liquid on the surface, can solve the problems of low dust removal and recovery efficiency, dust accumulation on the bottom surface, etc., and achieve high dust efficiency, The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

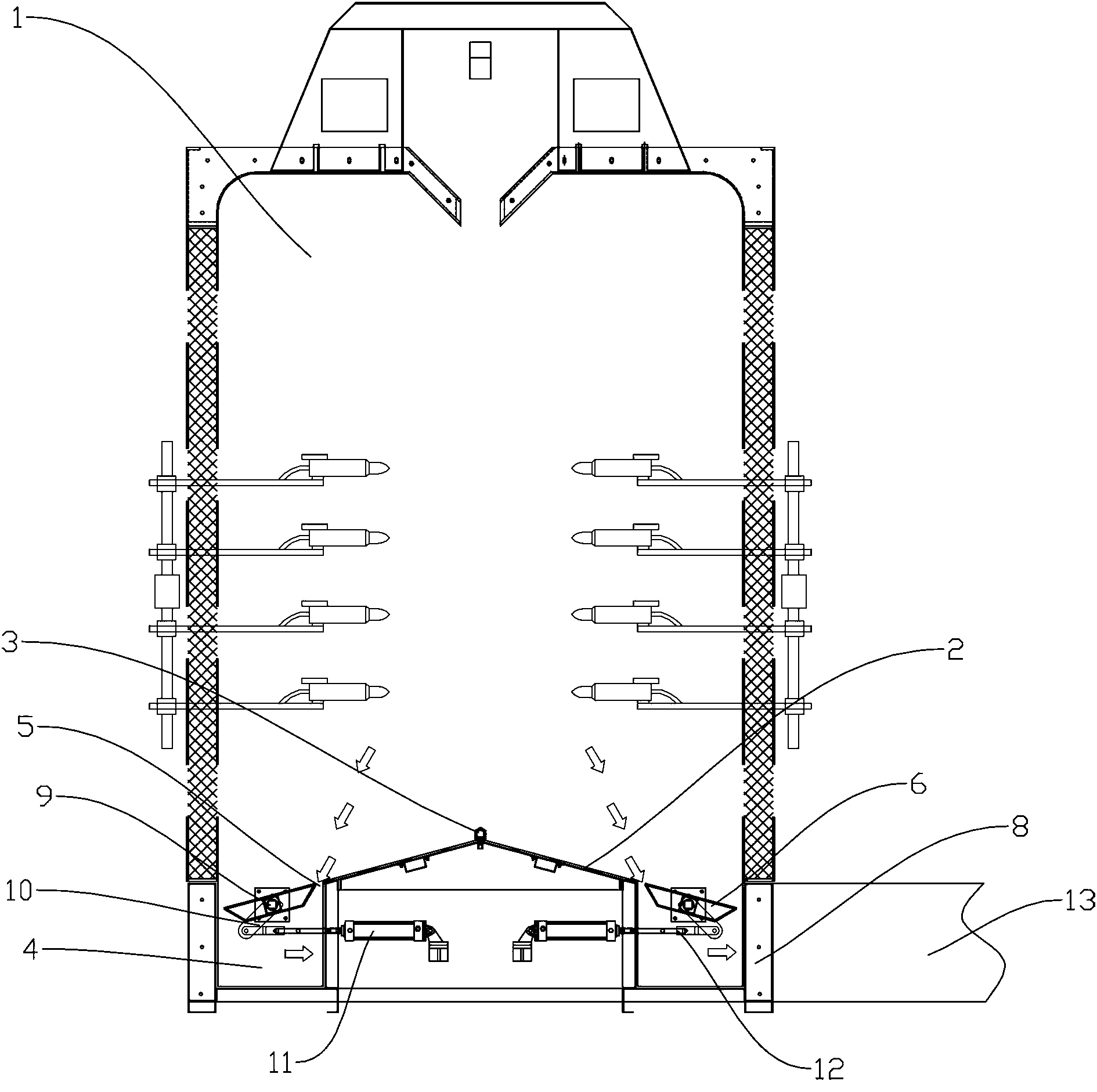

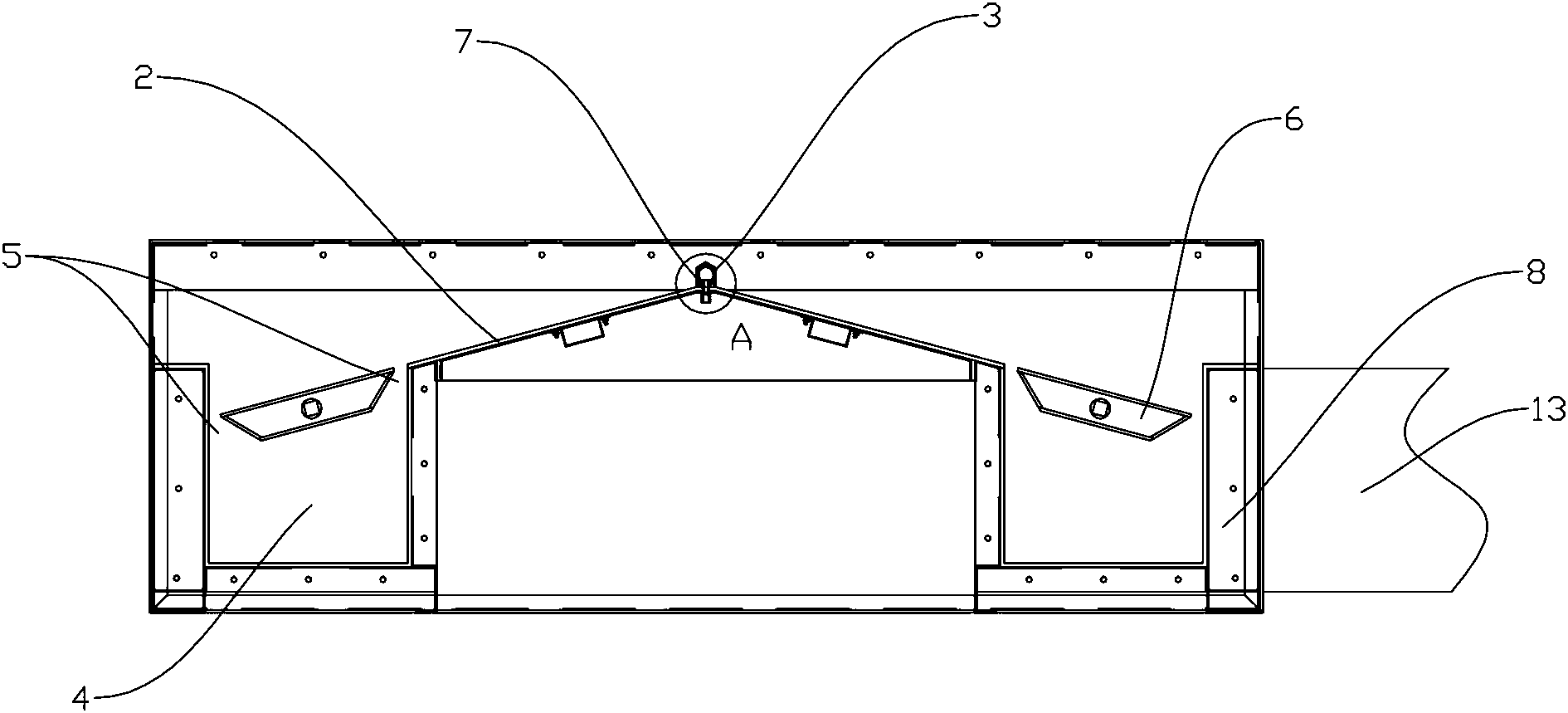

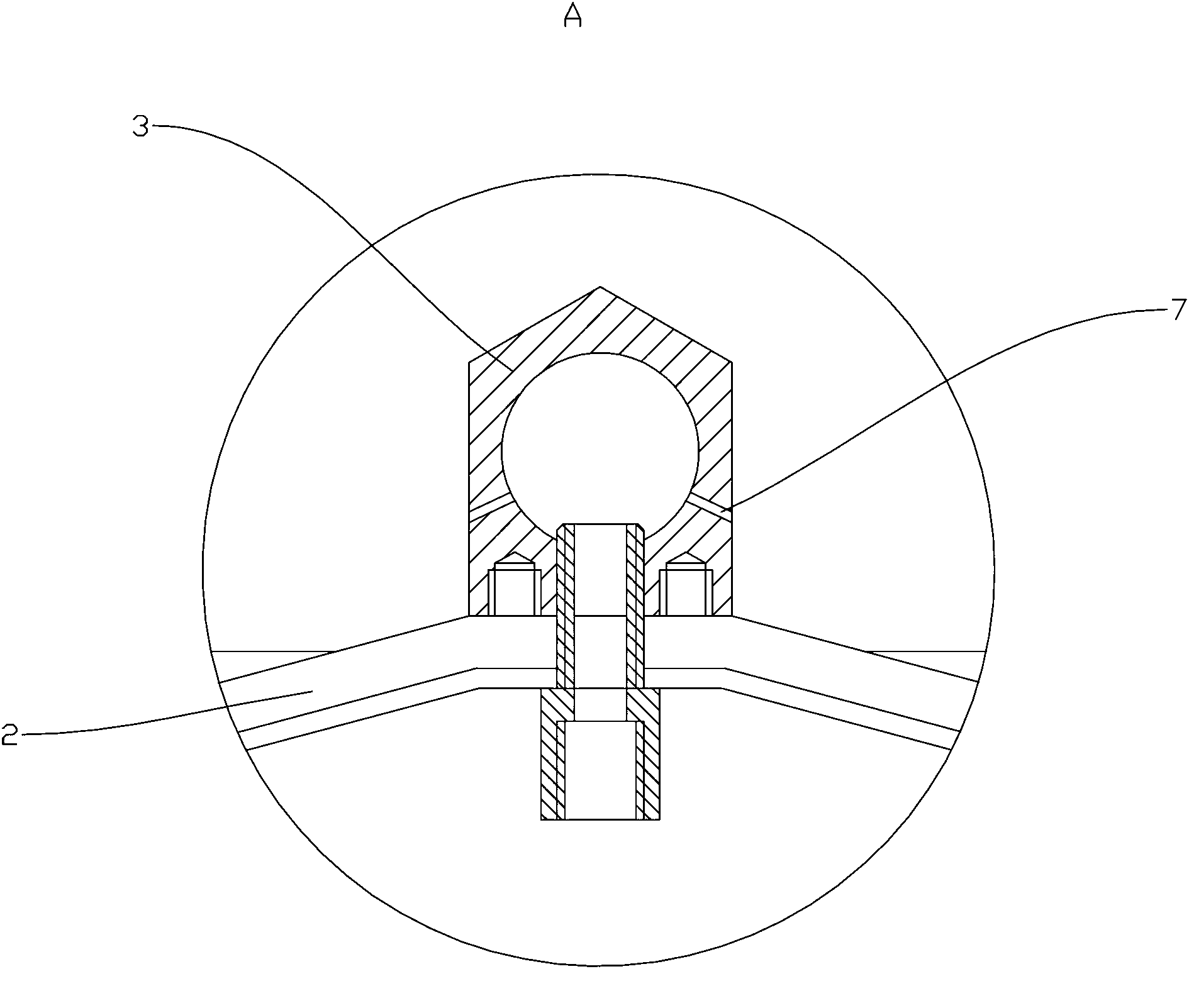

[0013] refer to figure 1 , figure 2 and image 3 , the present invention is a rapid color-changing spray booth with air knives double flaps in the convex bottom, which includes a spray booth body and a powder cleaning device arranged at the bottom of the spray booth body. The powder cleaning device includes a bottom plate 2 with an inverted V-shaped cross section, The air knife 3 arranged on the top of the bottom plate 2 and the recovery chamber 4 for dust recovery, the side wall of the air knife 3 is provided with a number of air holes 7, the air holes 7 are connected to the air source, between the two ends of the bottom plate 2 and the side wall of the spray booth body There is a gap 5, the inlet of the recovery chamber 4 communicates with the gap 5, the recovery chamber 4 is provided with an outlet 8 that can be connected to the dust removal system, and the outlet 8 can be connected to the next-level system through the air duct 13, and the air duct is made of PVC material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com