Chemical catalysis reactor

A technology of chemical catalysis and reactors, applied in the field of reactors, can solve the problems of widely varying reaction effects, achieve the effects of increasing residence reaction time, huge market prospects, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

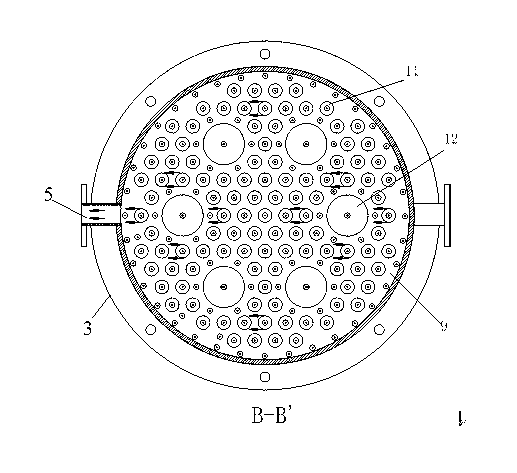

[0020] Such as Figure 1~Figure 5 As shown, this embodiment discloses a chemical catalytic reactor, comprising a reaction tank body 3, the lower end of the reaction tank body 3 is a material inlet, and the side wall of the reaction tank body 3 is provided with a material outlet 5; A first baffle plate 6 and a second baffle plate 7 are arranged upward, thereby dividing the inside of the reaction tank into a feed chamber 8 , a discharge chamber 9 and a reflux chamber 10 from bottom to top. A riser pipe 11 communicating with the feed chamber 8 and the return chamber 10 is provided between the first baffle plate 6 and the second baffle plate 7 . The second baffle 7 is provided with a return pipe 12 communicating with the return chamber and the discharge chamber. The material outlet 5 is located between the first baffle 6 and the second baffle 7 and communicates with the discharge chamber 9 . The feed chamber 8 is provided with a flow divider 1, including a trumpet-shaped housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com