Preparation method of cellulose ether-ethyl orthosilicate pervaporation hybrid membrane

A technology of tetraethyl orthosilicate and pervaporation, applied in chemical instruments and methods, semipermeable membrane separation, membrane technology, etc., can solve the problems of low separation factor, high cost, complicated membrane preparation process, etc., and achieve good separation Good effect, easy operation, controllability and production repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

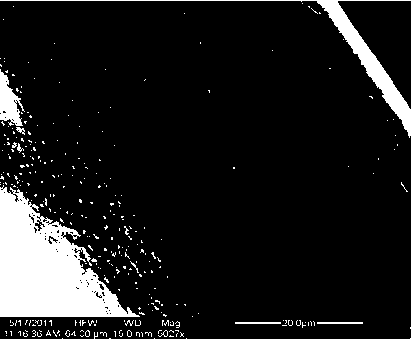

Image

Examples

Embodiment 1

[0026] Example 1: Weigh 4g of hydroxyethyl cellulose and dissolve it in 100g of distilled water, stir at 70°C until it dissolves completely, weigh 0.2g (5wt%, relative to HEC) TEOS, dissolve it in water to make it hydrolyzed, water and The molar ratio of TEOS is 5:1. Use hydrochloric acid to adjust the pH of the solution to between 1-3. After the solution reacts until it becomes clear, slowly add it into the hydroxyethyl cellulose solution and keep stirring to form a homogeneous transparent sol. Filter the obtained sol through a 2# sand core funnel to remove insoluble matter, let it stand still, and defoam to obtain a casting solution. Coat the sol on the surface of the polyacrylonitrile base film with a doctor blade, gel and dry at room temperature for 48 hours, then vacuum-dry at 60-70°C for 24 hours, soak the obtained film in the cross-linking solution for cross-linking, cross-linking The solution is 180mL of acetone-water solution (1:2, v / v), 2.5mL of hydrochloric acid, an...

Embodiment 2

[0027] Embodiment 2: The process steps as in Example 1, wherein only the amount of TEOS added is changed to 0.4g (10wt%, relative to HEC), and the hydroxyethyl cellulose organic-inorganic hybrid membrane of the present invention is prepared. When the feed liquid concentration (methanol wt%) is 90% and 95% respectively, the permeation flux J (g / m 2 h) are 270 and 235 respectively, and the separation factor α is 352 and 812 respectively.

Embodiment 3

[0028] Embodiment 3: The process steps as in Example 1, wherein only the amount of TEOS added is changed to 0.6g (15wt%, relative to HEC), and the hydroxyethyl cellulose organic-inorganic hybrid membrane of the present invention is prepared. When the feed liquid concentration (methanol wt%) is 90% and 95% respectively, the permeation flux J (g / m 2 h) are 193 and 157 respectively, and the separation factor α is 699 and 1319 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com