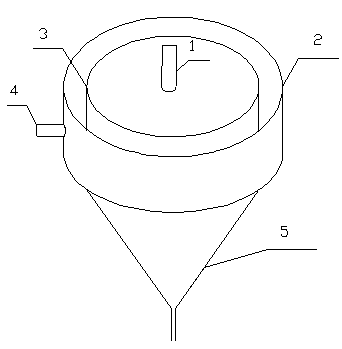

Sedimentation device

A settling device and gravity settling tank technology, applied in settling tanks, inorganic chemistry, molybdenum compounds, etc., can solve the problems of laborious and laborious manual cleaning, large area for settlement tanks, etc., to reduce construction area, improve utilization rate, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0012] This embodiment uses two gravity settling tanks. The production process of ammonium tetramolybdate: molybdenum concentrate is used as raw material, so it must be roasted to separate the molybdenum and sulfur in molybdenum disulfide, so that the molybdenum disulfide insoluble in ammonia can be converted into trioxide which is easily soluble in ammonia after roasting molybdenum. It must be heated to make it burn during roasting. The factors affecting the quality of molybdenum oxide during roasting are the temperature and the size of oxygen supply. Air compression blowing and induced draft fans are generally used for oxygen supply. The use of induced draft fans must take away some dust and sublimated molybdenum trioxide during the roasting process. In the recovery of dust and sublimated molybdenum trioxide, a cooling spray device is usually used to spray and settle the recovered dust and sublimated molybdenum trioxide, so that the solid-liquid mixture with dust and molybd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com