Motor-type automatic ultrasonic probe for elasticity imaging

An elastography, ultrasonic probe technology, applied in ultrasonic/sonic/infrasonic diagnosis, application, sonic diagnosis and other directions, can solve problems such as pressure blind area, large contact area, inability to accurately judge the elasticity difference of the inspection site, etc., to improve quality, Improve work efficiency and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

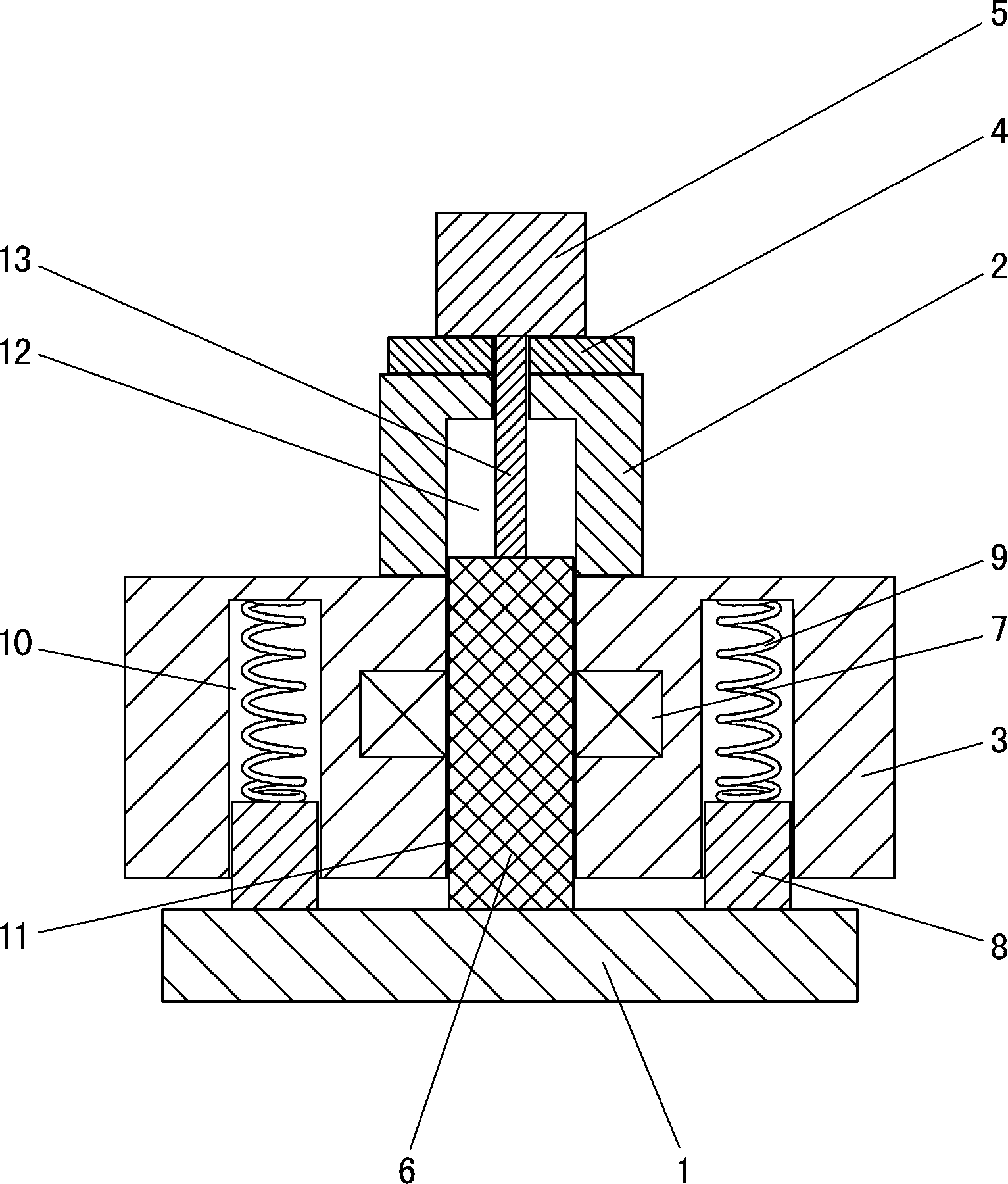

[0013] Such as figure 1 As shown, this motor-type automatic ultrasonic probe for elastography includes a probe core 1, a handle 2, a probe base 3, a connecting base 4, a linear motor 5, a sliding shaft 6, a sliding bearing 7, a pressure sensor 8 and a spring 9. The probe base 3 is provided with a sensor cavity 10 and a first sliding channel 11 that runs through the upper and lower surfaces of the probe base 3; the handle 2 is installed on the top of the probe base 3; the handle 2 is provided with a second sliding passage that penetrates the upper and lower surfaces of the handle 2 Channel 12, the second sliding channel 12 communicates with the first sliding channel 11; the sliding bearing 7 is installed in the first sliding channel 11; the probe core 1 is under the probe base 3, the sliding shaft 6 is in the sliding bearing 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com