Noodle machine with rapid machining

A noodle machine, fast technology, applied in the direction of dough extruder, dough processing, mixing/kneading with vertical installation tools, etc. It can solve the problems of sticking stirring rods, reduced processing efficiency of noodle machines, and difficulty in entering noodles, etc. To achieve the effect of prolonging the service life of the whole machine, reducing the single processing time, and being easy to process and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

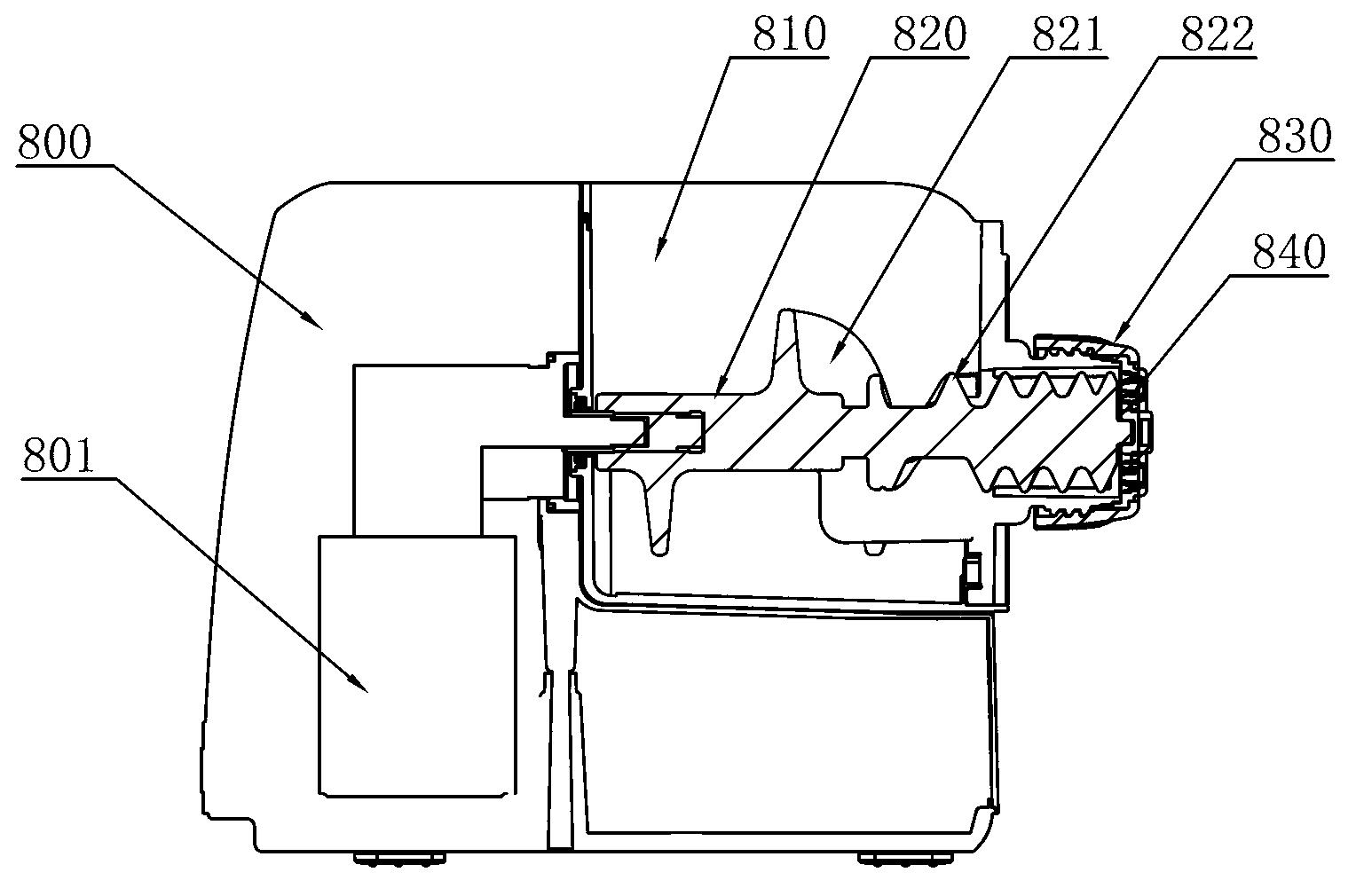

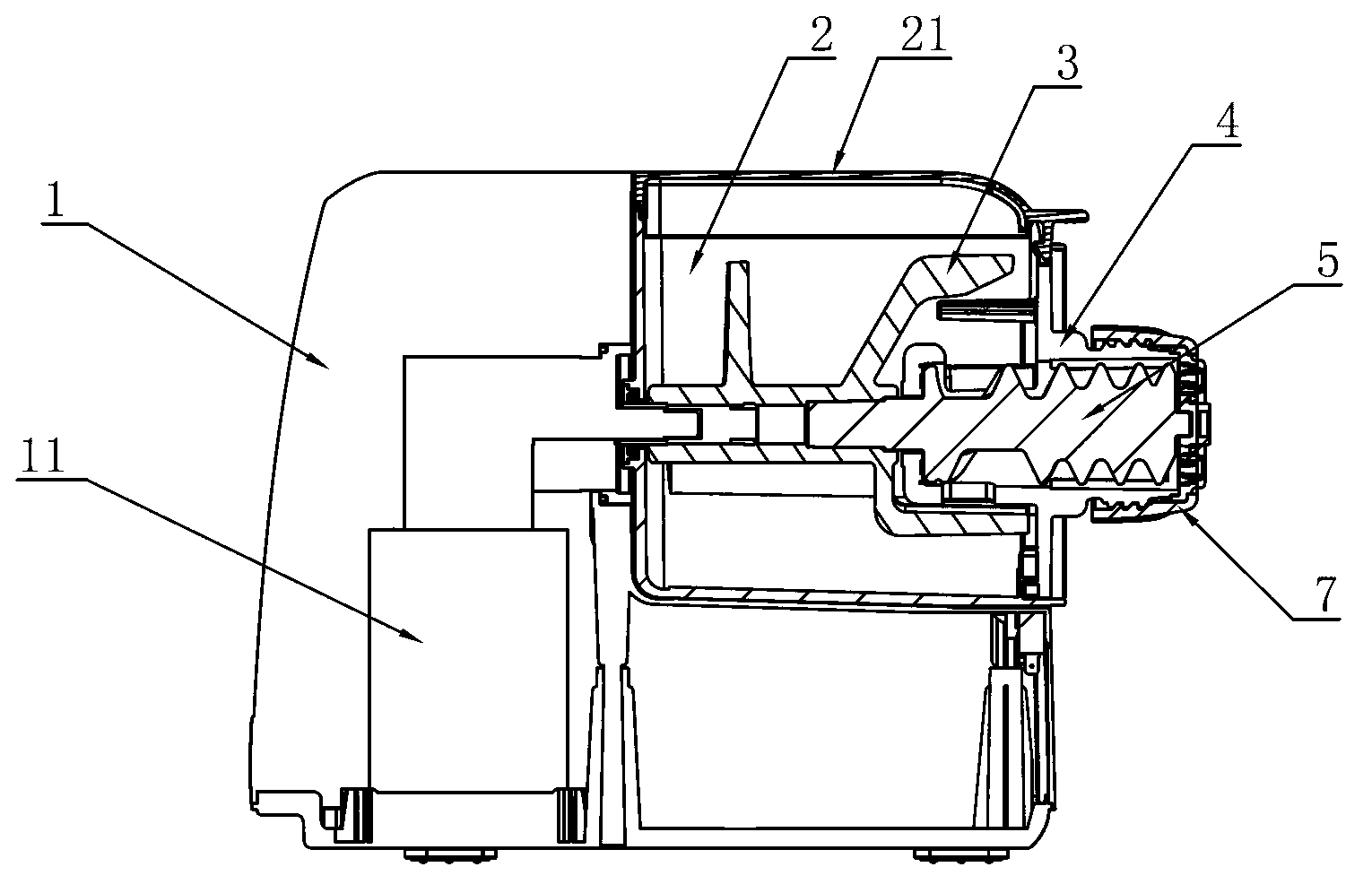

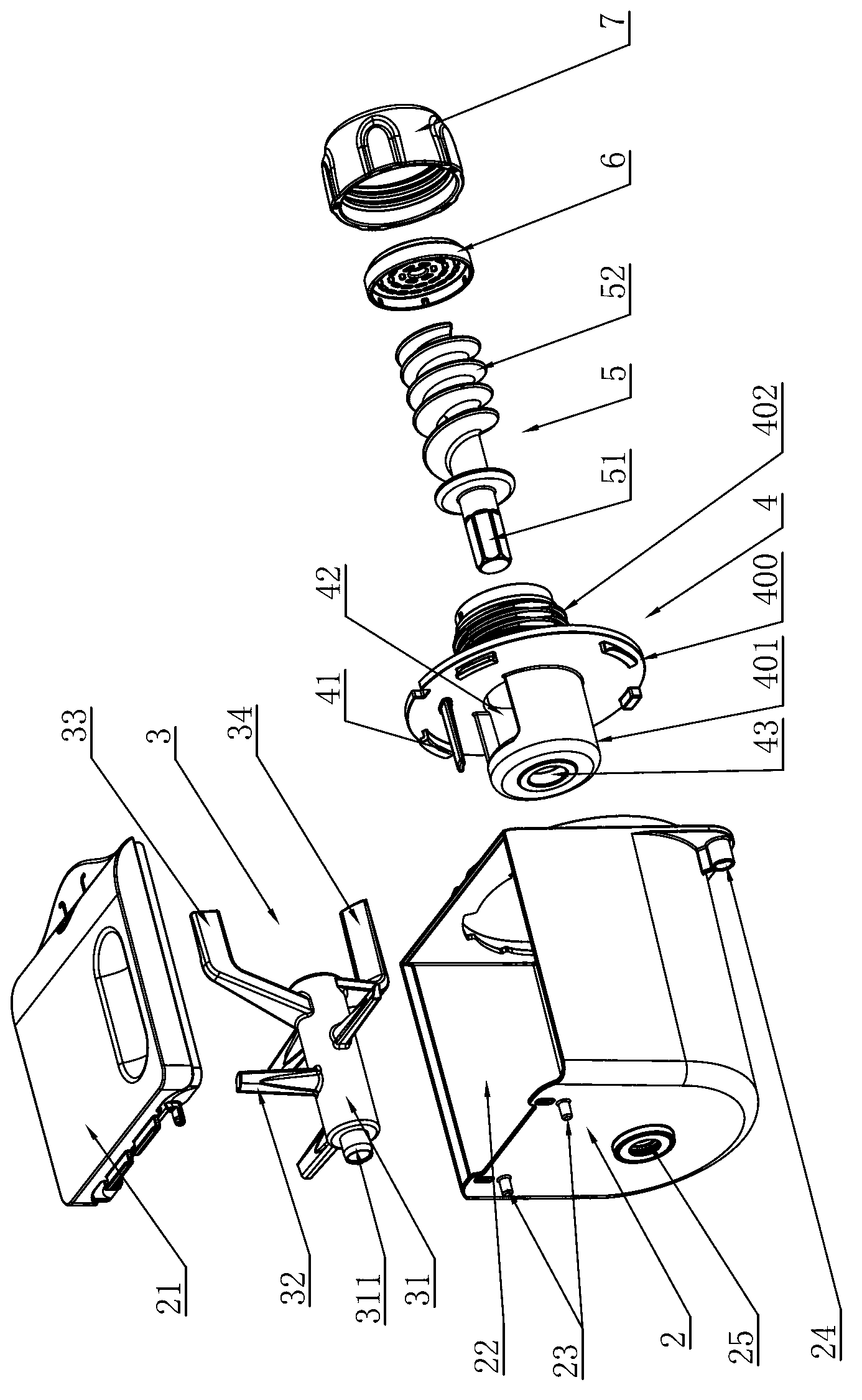

[0038] Such as figure 2 As shown, the noodle machine includes a machine base 1, a stirring cup 2, an upper cover 21, a stirring rod 3, a feeding cylinder 4, a screw rod 5, and an end cover 7. The motor base 1 is provided with a motor 11, the stirring cup 2 is arranged on the base 1 and connected with the base 1, the stirring cup 2 is provided with a stirring assembly and an extruding assembly, the stirring The assembly includes a stirring rod 3 , the extruding assembly includes a feeding barrel 4 and a screw 5 matched with the feeding barrel 4 , and an end cover 7 is provided at the front end of the feeding barrel 4 . An upper cover 21 is also provided above the stirring cup 2 .

[0039] Such as image 3 , 4 As shown, a stirring chamber 22 is formed inside the stirring cup 2 , and the upper cover 21 covers the opening of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com