Control method for barley safe storage

A technology of safe storage and control method, which is applied in the control field of safe storage of barley, can solve the problems such as the drop of germination rate in five days, and achieve the effects of eliminating economic losses, overcoming hysteresis, and ensuring quality and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A control method for safe storage of barley, comprising the following steps:

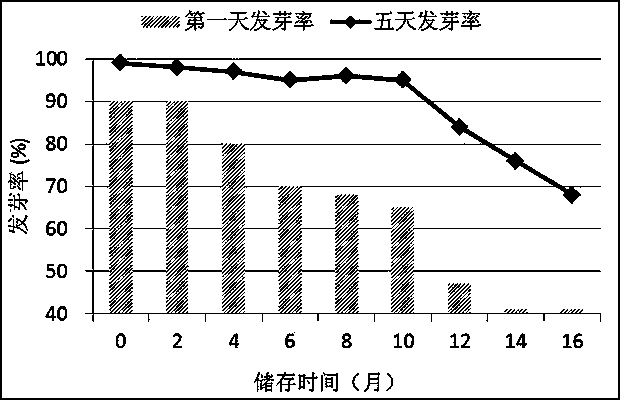

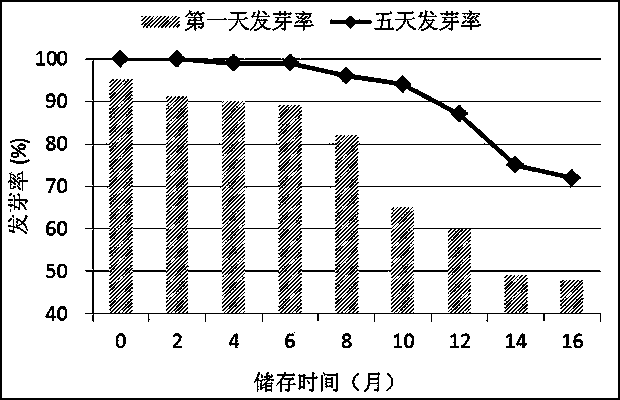

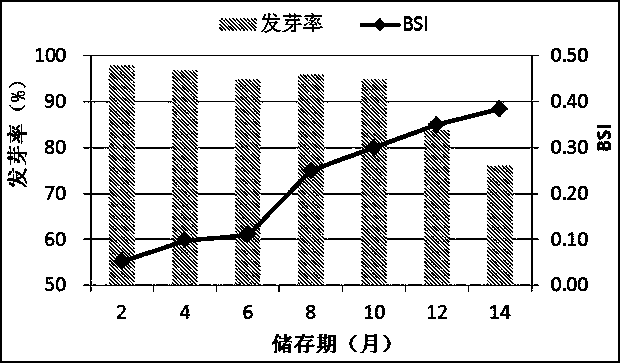

[0041] ① detecting the germination rate of barley: detecting the germination rate of barley for five days and the germination rate of the first day, the second day and the third day; the specific steps of the barley germination rate detection are:

[0042] (a) Put two pieces of filter paper with a diameter of 9cm into the bottom of the Petri dish, add 4ml of water to evenly wet the filter paper;

[0043] (b) Take 100 samples and put them on the filter paper, so that each grain is in good contact with the filter paper, and cover the petri dish;

[0044] (c) Put the petri dish into a plastic bag and seal it tightly to prevent water from evaporating, and germinate in a dark place at a room temperature of 18-20°C;

[0045] (d) Count the number of germinated barley grains after standing for 24h, 48h, 72h and 120h respectively, and obtain the germination rate of barley on the first day, the second d...

Embodiment 2

[0059] A control method for safe storage of barley, wherein the barley is Gamai Copeland and Omai Baudin, comprising the following steps:

[0060] ① detecting the germination rate of barley: detecting the germination rate of barley for five days and the germination rate of the first day, the second day and the third day; the specific steps of the barley germination rate detection are:

[0061] (a) Put two pieces of filter paper with a diameter of 9cm into the bottom of the petri dish, add 4ml of water to evenly wet the filter paper;

[0062] (b) Take 100 grain samples and put them on the filter paper, so that each wheat grain is in good contact with the filter paper, and cover the petri dish;

[0063] (c) Put the petri dish into a plastic bag and seal it tightly to prevent water from evaporating, and germinate in a dark place at a room temperature of 18-20°C;

[0064] (d) Count the number of germinated barley grains after standing for 24h, 48h, 72h and 120h respectively, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com