Miniature drive motor

A micro-drive and motor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of low production efficiency, high defect rate, cumbersome installation and manufacturing, etc. The effect of driving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (Embodiment 1, micro drive motor)

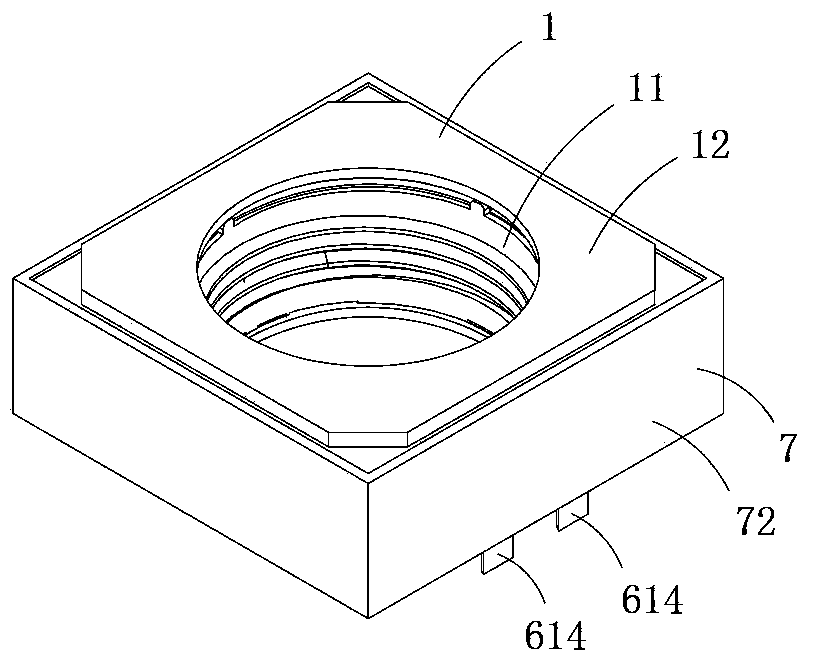

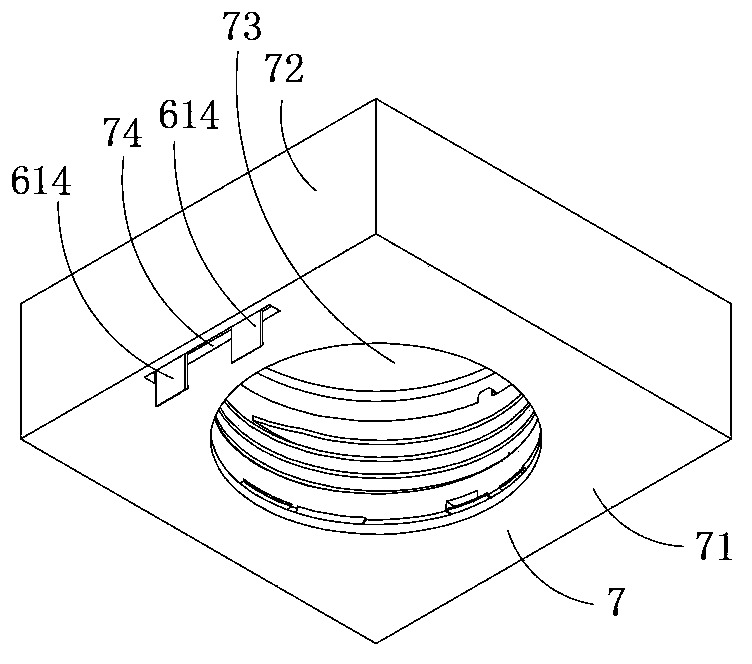

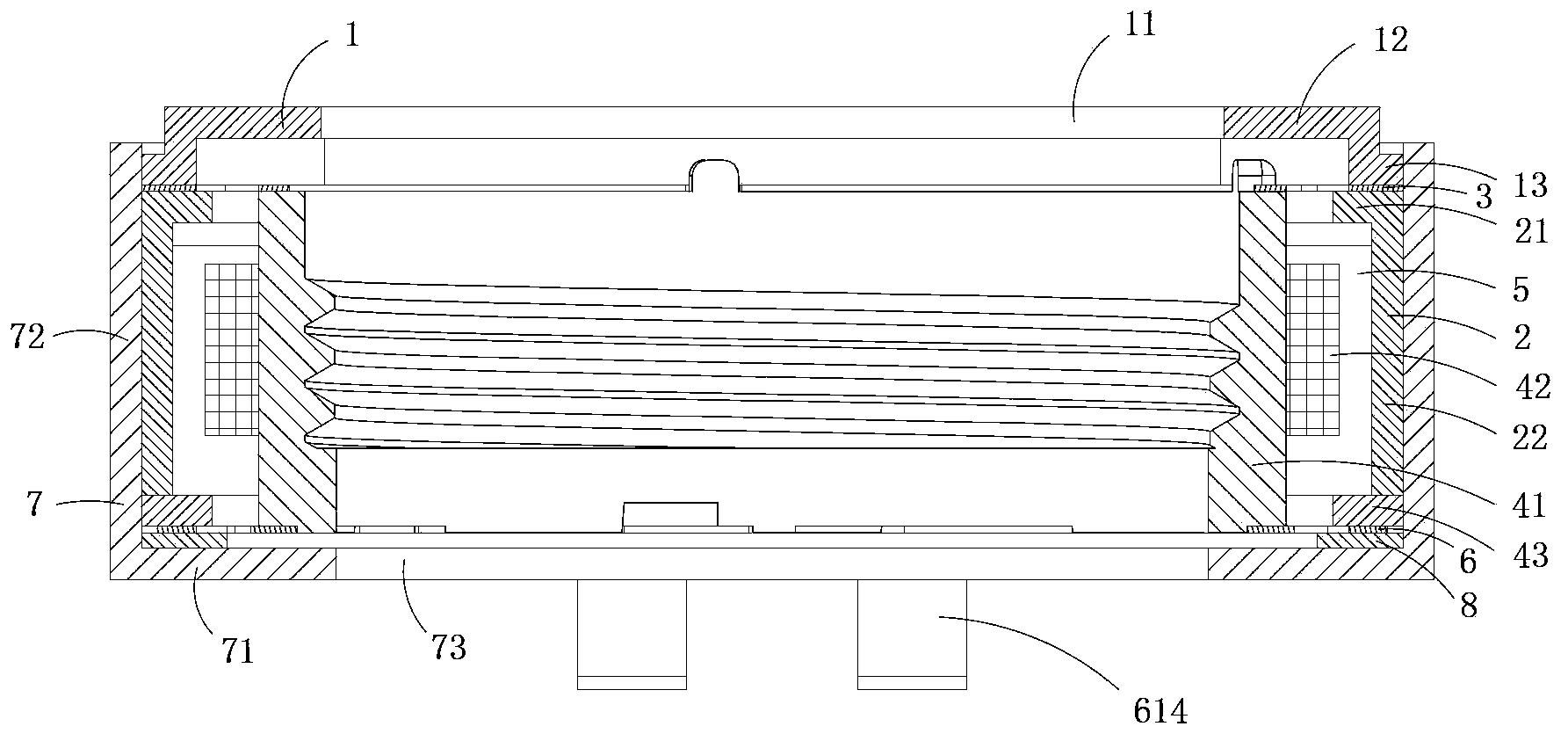

[0021] Figure 1 to Figure 5 A specific embodiment of the micro drive motor in the present invention is shown, wherein, figure 1 It is a schematic diagram of a three-dimensional structure of the first structure of the present invention; figure 2 yes figure 1 A schematic diagram of the three-dimensional structure of the micro-drive motor when viewed from another angle; image 3 yes figure 1 A cutaway view of the micro drive motor shown; Figure 4 yes figure 1 An exploded view of the micro-drive motor shown; Figure 5 yes figure 1 An exploded view of the miniature drive motor shown when viewed from another angle.

[0022] Present embodiment is a kind of miniature drive motor that drives miniature camera lens assembly, see Figure 1 to Figure 5 As shown, it includes an upper cover 1, an upper gasket 2, an upper spring sheet 3, a lens carrier 41, a magnet assembly 5, a coil assembly 42, a lower gasket 43, a lower spring sheet as...

Embodiment 2)

[0027] Figure 6 It is a cross-sectional view of the second structure of the present invention, showing the second specific implementation manner of the present invention.

[0028] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 As shown, in this embodiment, no crimping boss 13 is provided at the bottom of the upper cover plate 12, but a frame-shaped pressing plate 9 is provided between the upper cover 1 and the outer ring 31 of the upper spring leaf 3, the upper cover 1 The cover 1 is crimped on the pressing plate 9 , and then the outer ring 31 of the upper spring piece 3 is crimped on the frame-shaped plate body 21 of the upper gasket 2 .

[0029] In addition, the upper cover 1 in this embodiment is made of non-magnetic material, and the base 7 is made of magnetic material. In this structure, a magnetic circuit passing through the coil assembly 42 is generated between the side of each magnet 51 close to the coil assembly 42 and the b...

Embodiment 3)

[0031] This embodiment is basically the same as Embodiment 1, except that the upper cover 1 and the base 7 in this embodiment are both made of magnetically permeable materials. This structure can effectively improve the utilization efficiency of the magnetic field of the magnet assembly, and can provide a more constant magnetic field for the coil assembly when the coil assembly moves with the carrier, thereby effectively improving the linear driving effect.

[0032] It can be seen from the above embodiments 1 to 3 that when the present invention is assembled, it only needs to be installed and fixed one by one in the order of first down and then up, and its process and operation are relatively simple; The special shape structure can accurately control the distance between the outer ring of the upper spring piece and the outer edge of the lower spring piece, so as to effectively ensure that the elastic deformation of the upper spring piece and the lower spring piece just offsets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com