Multi-slot lighting device

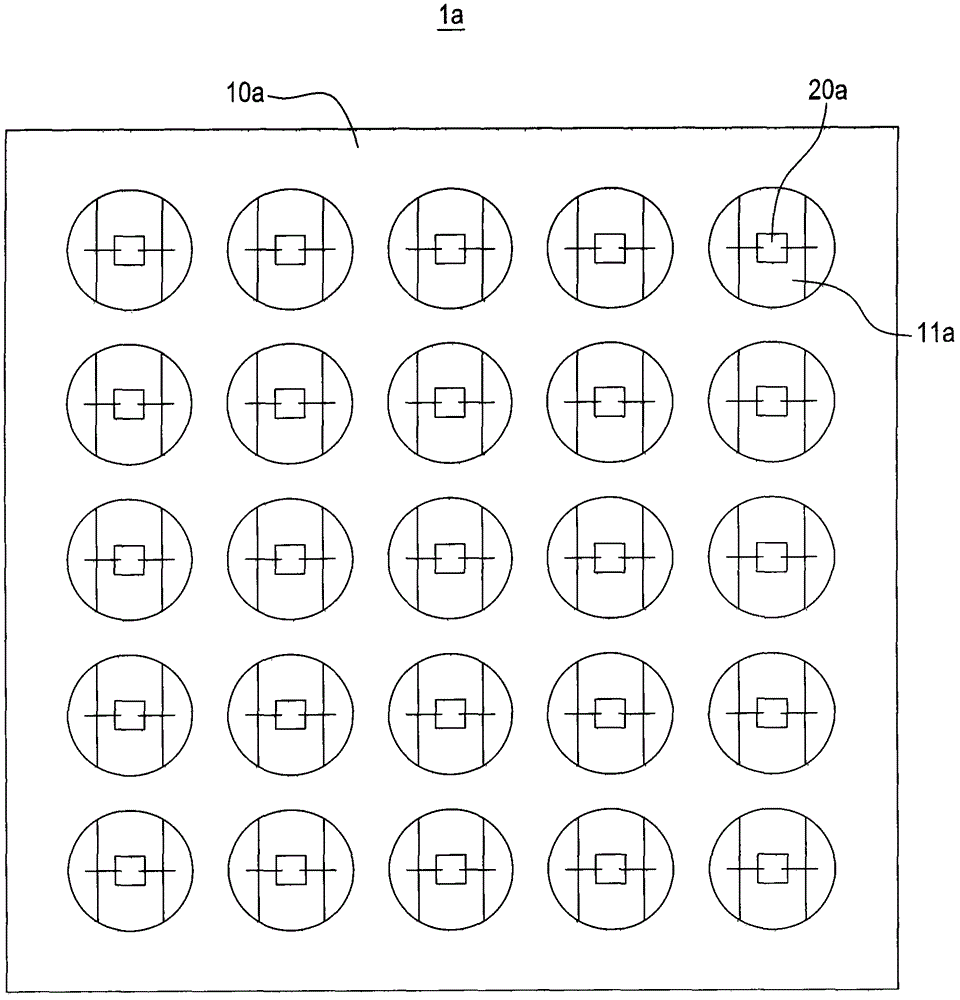

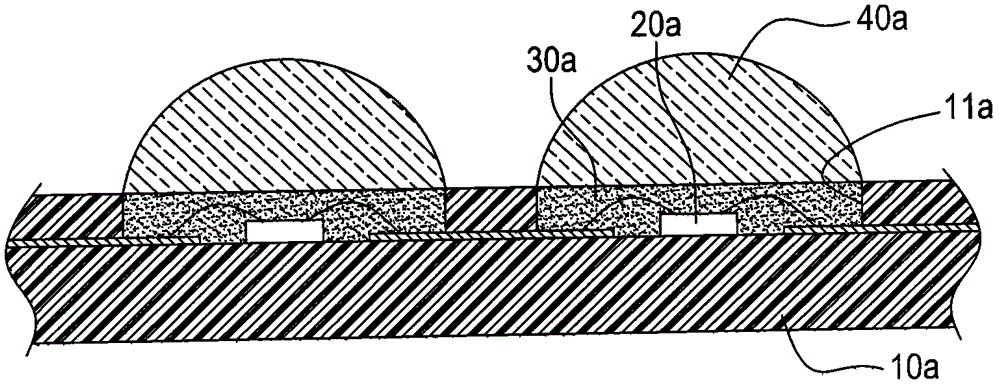

A light-emitting device and slot-type technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of affecting the strength of the substrate 10a, increasing the assembly time and cost, and breaking the substrate 10a, thereby increasing practicability and reducing assembly. Working hours and time, the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are provided for reference and illustration only, and are not intended to limit the present invention.

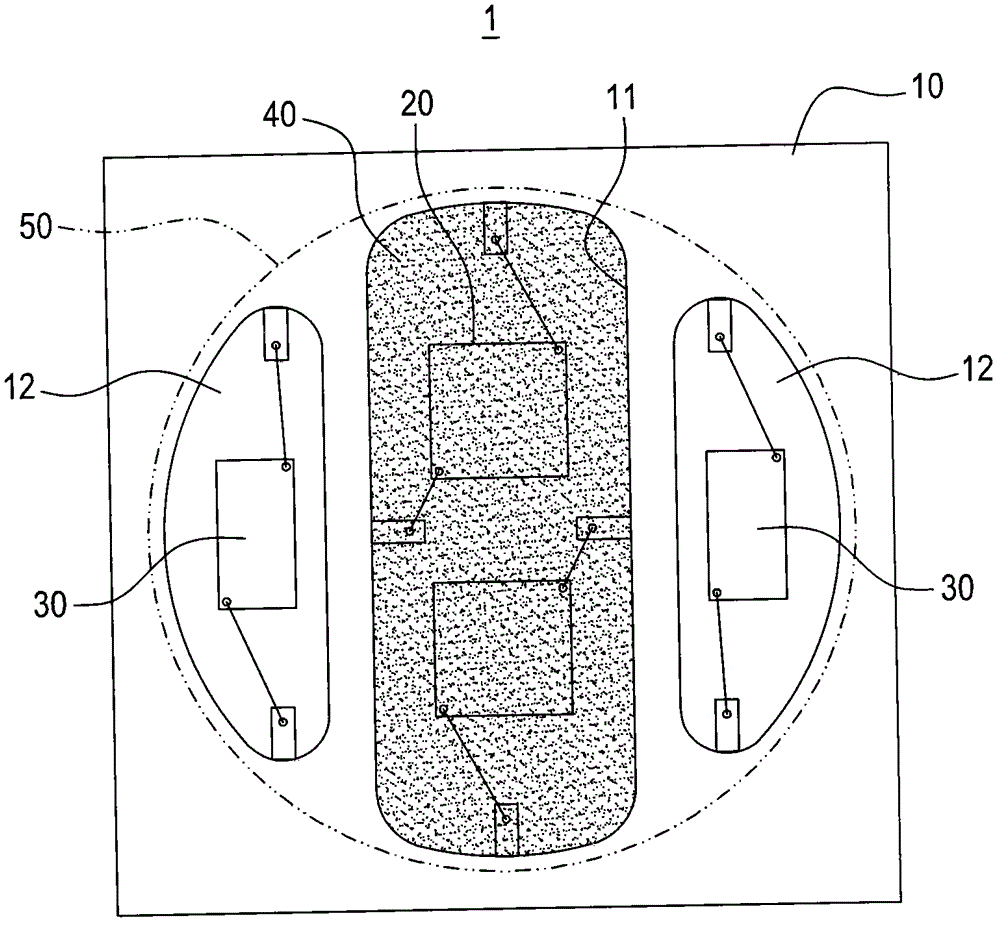

[0035] Please refer to image 3 and Figure 4 , are respectively a schematic plan view and a cross-sectional view of the multi-slot light emitting device of the present invention; the multi-slot light emitting device 1 of the present invention includes a base 10, a first light emitting unit 20, at least two second light emitting units 30, a light conversion Layer 40, and a lens 50.

[0036] The base 10 has a central groove 11 and at least two side grooves 12 symmetrically disposed outside the central groove 11 . The base 10 can be configured as a ceramic base, and has a plurality of conductive vias 13 and an inner circuit 14 , which is not limited in actual implementation.

[0037] In this embodiment, the first ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com