Low-temperature methanol-methanol winding tubular heat exchanger design and calculation method

A low-temperature methanol, winding-tube technology, applied in computing, instrumentation, special data processing applications, etc., can solve the problem that there is no general design standard, no unified heat exchange process design calculation method, low-temperature methanol-methanol winding tube heat exchanger Problems such as obstacles to the scientific calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

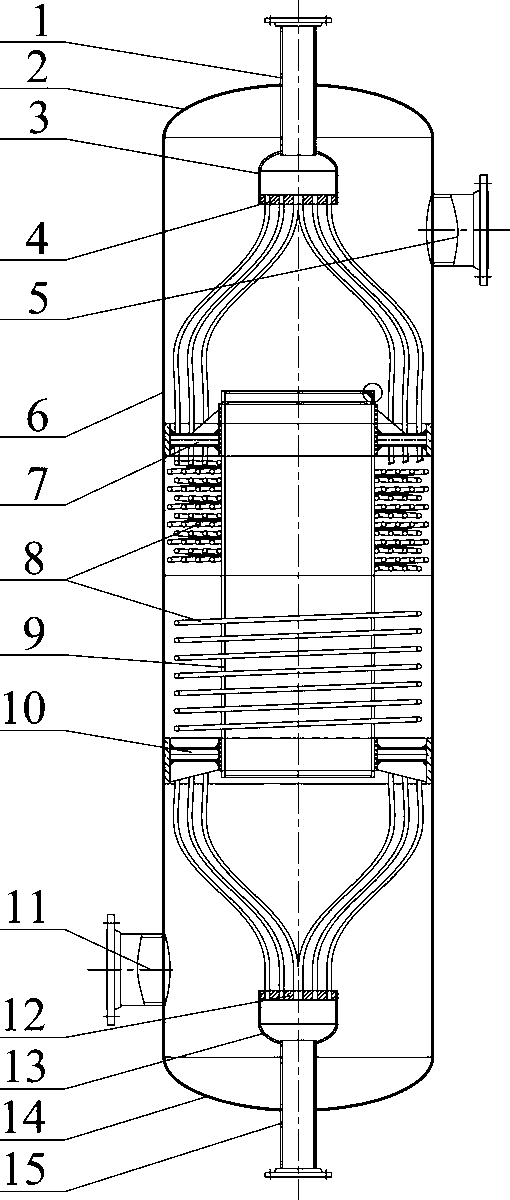

[0147]First, the basic structure of the low-temperature methanol-methanol winding tube heat exchanger is designed in the form of countercurrent heat exchange. Upper tube sheet (4), shell side outlet connection (5), shell (6), upper support ring (7), spiral tube bundle (8), core barrel (9), lower support ring (10), shell side inlet Connecting pipe (11), built-in lower tube plate (12), built-in lower tube box (13), shell lower head (14), tube outlet connecting pipe (15), etc.; design low-temperature methanol-methanol winding tube heat exchanger The tube bundle (8) is wound around the core tube (9) and installed between the upper support ring (7) and the lower support ring (10) in the shell (6); the low temperature methanol-methanol wound tube heat exchanger has an independent The built-in upper pipe box (3) built in the shell, the upper part of the built-in upper pipe box (3) is connected to the inlet pipe of the pipe (1), the lower part is connected to the built-in upper tube p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com