Gap width adjustment device

A technology of width adjustment and cracking, applied in the direction of installation, lasers, instruments, etc., can solve the problems of difficult precise control and long time consumption, and achieve the effect of improving forming time and precision and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments according to the present invention will be described below with reference to the drawings. However, the present invention is not limited to the embodiments disclosed below, and various forms different from each other can be realized. This embodiment is provided only for the purpose of disclosing the present invention and fully informing those skilled in the art about the scope of the present invention. .

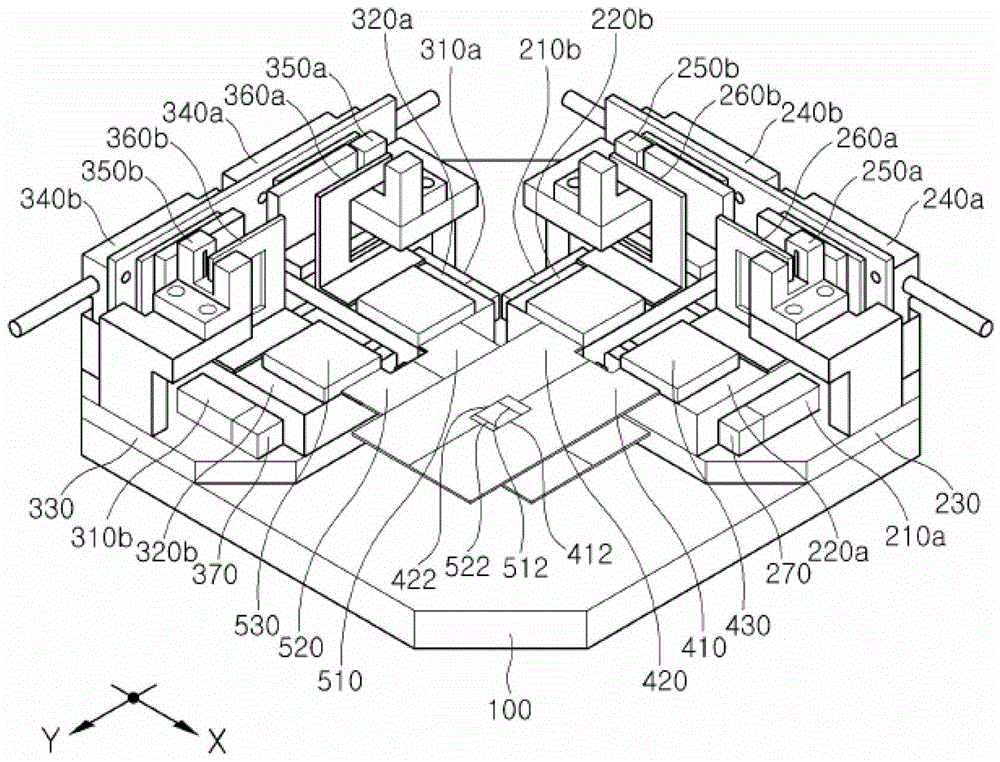

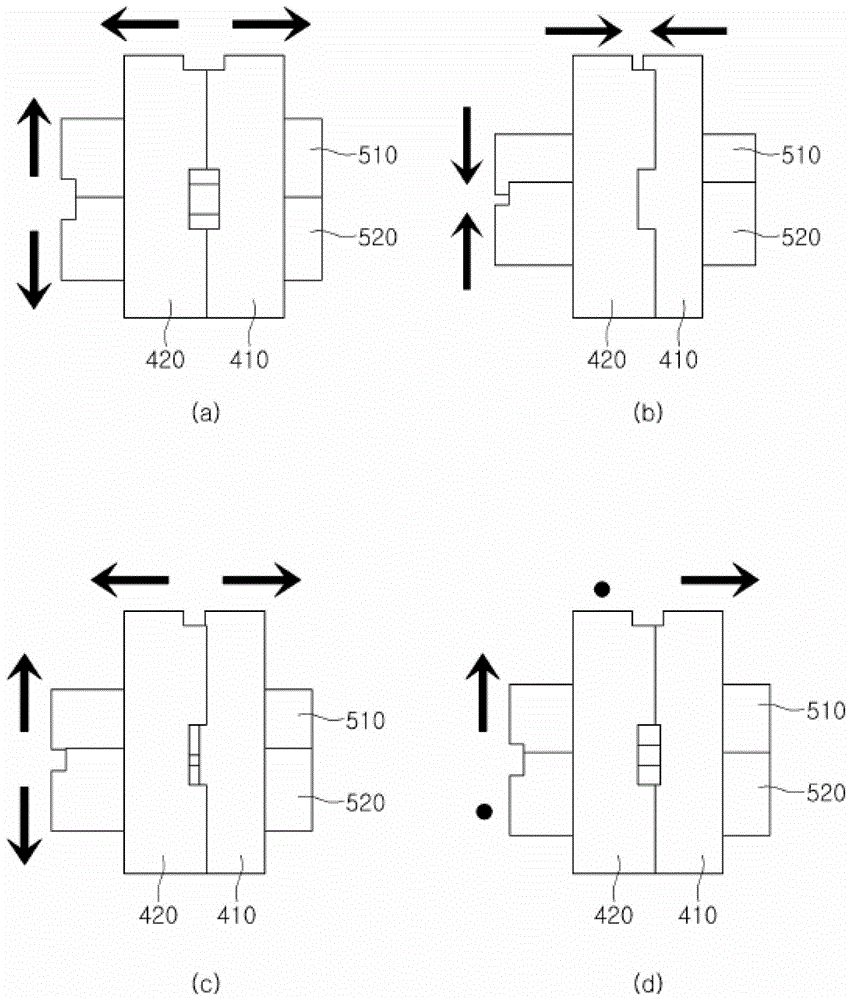

[0036] figure 1 It is an oblique view of a gap width adjusting device according to an embodiment of the present invention, figure 2 As a side oblique view, the main components of the gap width adjusting device will be mainly described below.

[0037] refer to figure 1 and figure 2 , according to the embodiment of the present invention, the gap width adjusting device includes: a platform 100; for example, a first linear motor 200, which is arranged on the X-axis edge of the platform 100; for example, a second linear motor 300, which is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com