Forecasting method for influences, on electrical performances, of array surface morphology of conformal load-bearing microstrip antenna

A technology of microstrip antenna and prediction method, which is applied in the field of electromechanical comprehensive analysis, design and compensation control of antenna, conformal bearing microstrip antenna, and can solve the problems of lack of prediction method, long period and development cost of the influence of front shape and electrical performance advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in further detail below with reference to the accompanying drawings.

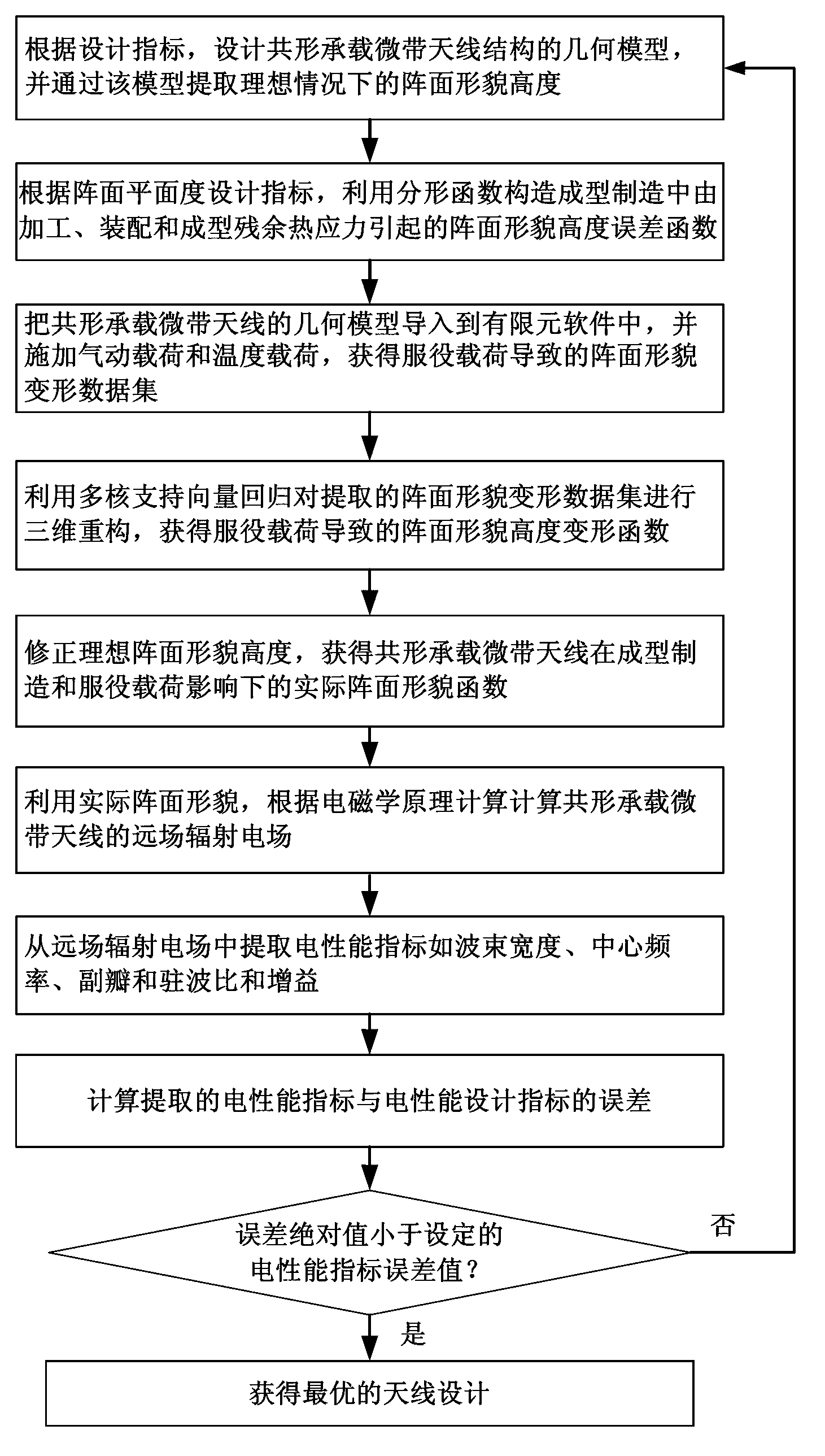

[0077] refer to figure 2 , the implementation steps of the inventive method are as follows:

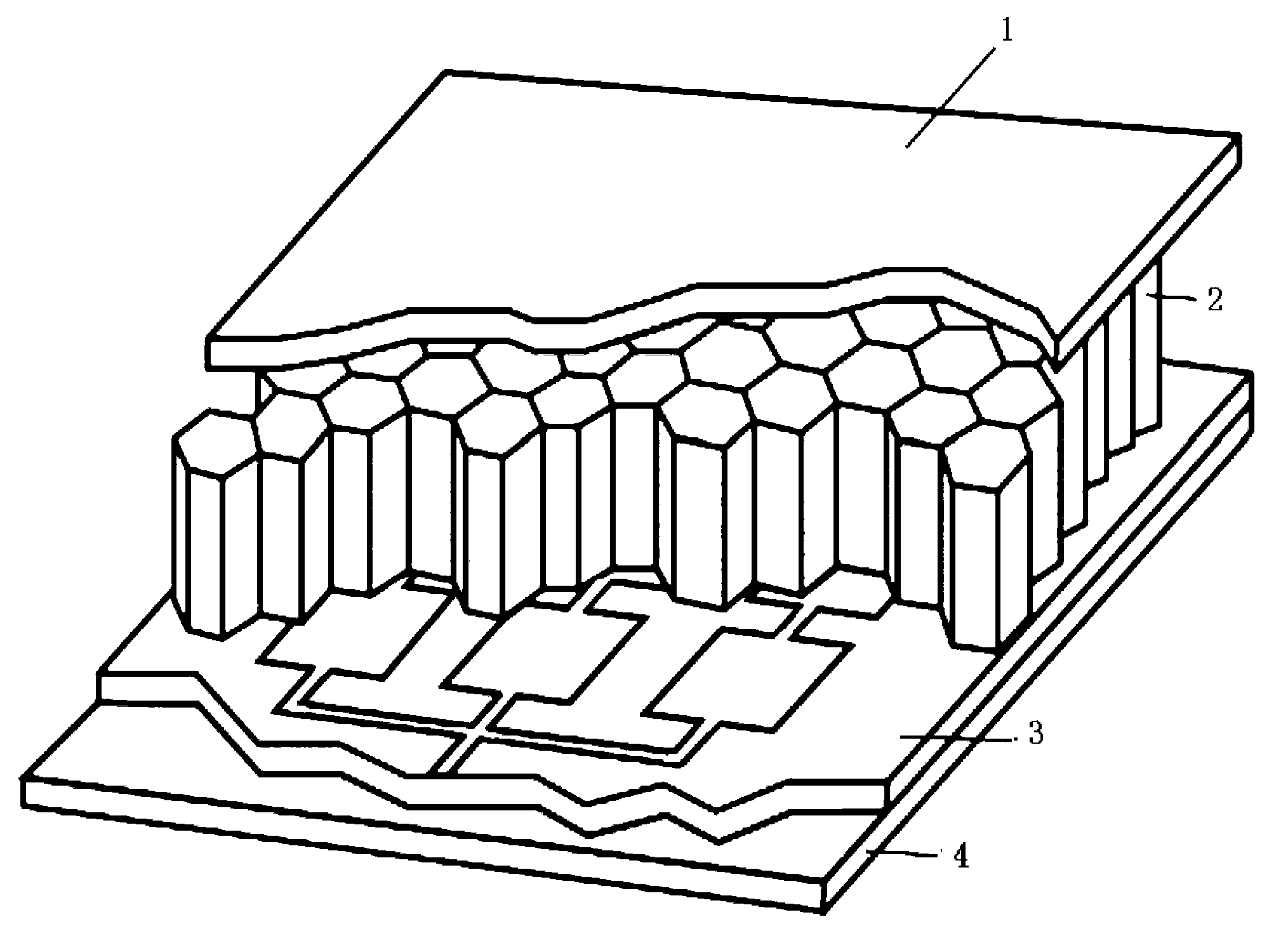

[0078] In the first step, according to the antenna’s electrical performance design index d and structural performance index s, the geometric model of the conformal load-carrying microstrip antenna is designed, and the ideal front profile height S is extracted from the model 0 (x, y), where x, y represent the abscissa and ordinate of the front profile, respectively.

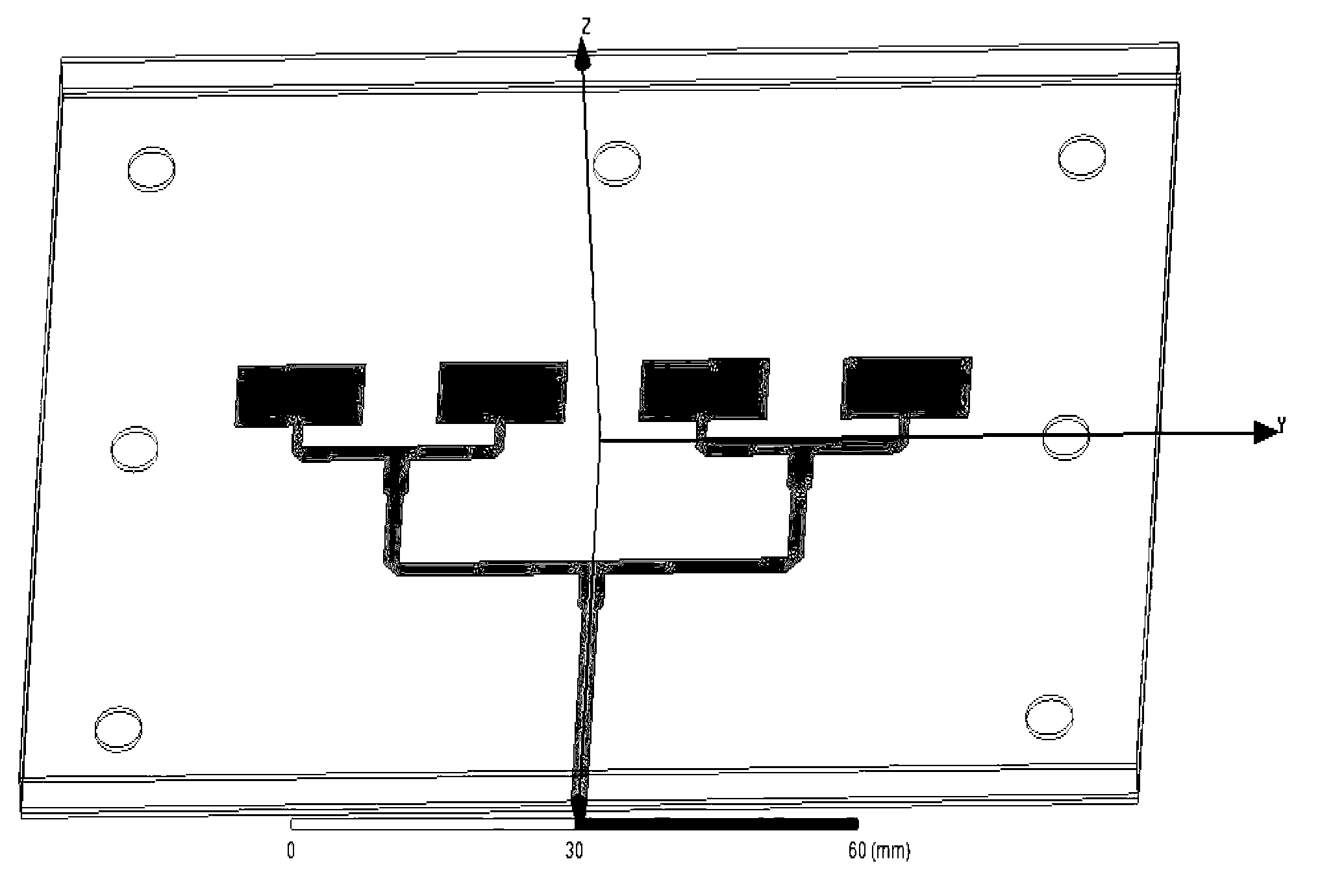

[0079] In this example, the electrical performance design index d of a given antenna includes a center frequency f of 12.5GHz, a standing wave ratio v of 1.5, a beam width bw of 14.5GHz, a gain g of 13dB, and a sidelobe sl of 13.5DB, and the vector d =[bw,f,sl,v,g] T Indicates these electrical performance indicators. The structural performance indicators s include structural tensile and compressive str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com