Full-airplane horizontal measurement method based on work space measurement location system

A work space and positioning system technology, which is applied to measurement devices, instruments, and optical devices, etc., can solve problems such as the influence of proficiency, low measurement efficiency, and poor measurement accuracy, and requires less number of people and technical levels. Small measurement workload, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

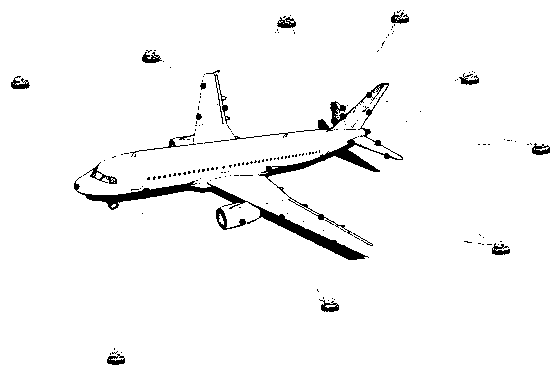

[0014] Such as figure 1 As shown, the aircraft level measurement method based on the working space measurement and positioning system includes the following steps:

[0015] (1) Determine the measurement workspace according to the external dimensions of the measured aircraft and the positions of the measurement points, and determine the number of laser scanning base stations to be 9, so that each measurement point is located at the optimal working distance of 6m from the laser emission base station, and two The intersection angle of the laser emitted by the laser transmitting base station is 90°, and the measurement point is guaranteed to be unobstructed, which has good measurability;

[0016] (2) Use the reference ruler to calibrate the external parameters of the measurement workspace formed by all laser scanning base stations, and establish the coordinate system of the workspace measurement and positioning system;

[0017] (3) Select three reference points on the aircraft fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com