Lever type magnetic suspension brake

A brake and lever technology, applied in the field of lever-type maglev brake, can solve the problems of complex brake structure, inconvenient installation and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

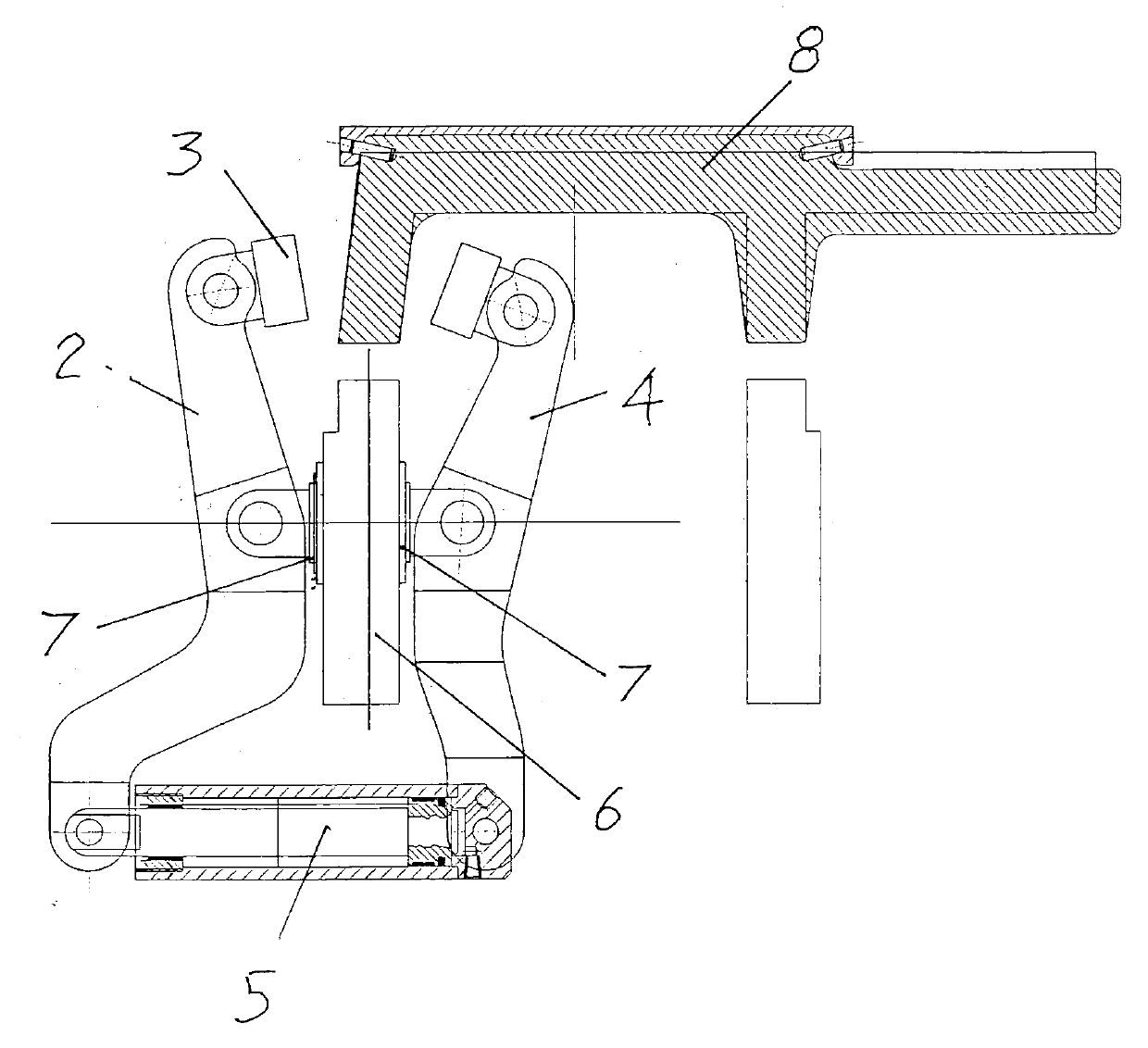

[0010] like figure 1 The shown lever-type magnetic suspension brake includes a rubber spring, an outer lever device, a brake pad, an inner lever device, a hydraulic cylinder, and a pole plate. The lever-type magnetic suspension brake is a pincer-shaped structure composed of an outer lever device and an inner lever device. There is a rubber spring between the axle frame and the pole plate. The upper ends of the outer lever device and the inner lever device are connected to the brake pads by pin shafts on the inner surface opposite to the upper end of the outer lever device. sides of the cylinder.

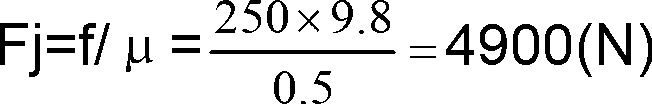

[0011] its parameters

[0012]

[0013] its characteristics

[0014] 1) Realize the limit displacement of the brake arm ±10mm.

[0015] 2) Realize the small up and down swing of the brake pads to cope with the inclination angle of the track and prevent eccentric wear.

[0016] 3) Good sealing performance.

[0017] 4) Easy to maintain and install.

[0018] 5) The friction pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com