Three-eccentric combined bolt and construction process thereof

A construction technology and eccentric technology, applied in the direction of connecting members, pins, mechanical equipment, etc., can solve the problem of no eccentric setting, etc., and achieve the effect of convenient and detachable installation, low cost and strong force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

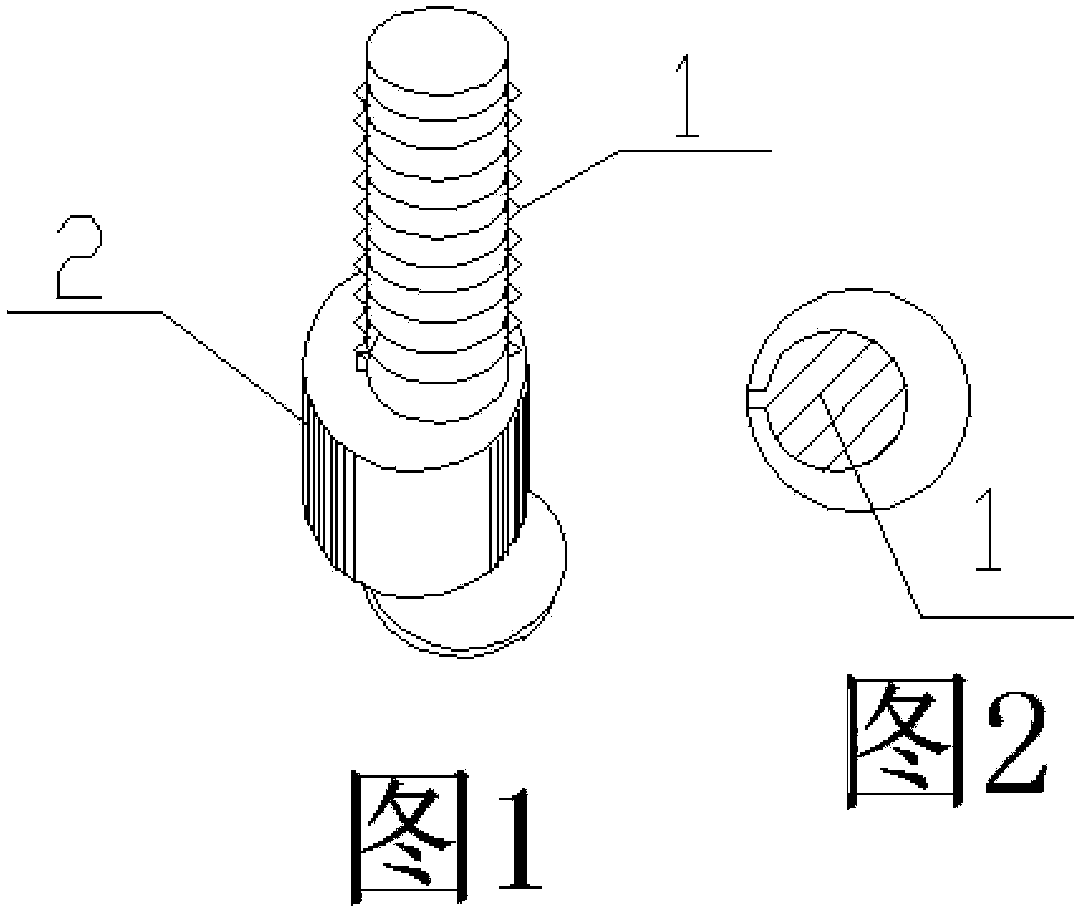

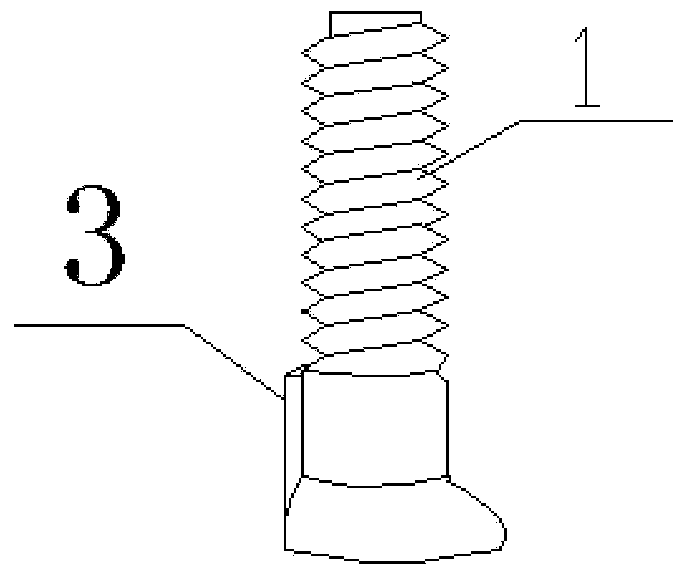

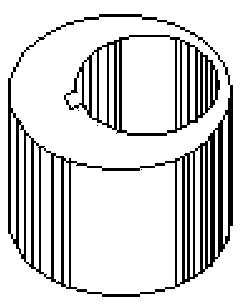

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the three-eccentric combination bolt of the present invention includes an eccentric head bolt 1 and an eccentric sleeve 2, the eccentric head bolt 1 includes a screw rod, a polished rod and an eccentric head, and there is a section of polished rod between the bolt and the eccentric head, and its structural characteristics In order to be provided on the polished rod with the same or almost the same direction as the center line of the screw rod 3, the inner side of the eccentric sleeve 2 is provided with a concave groove that can be inserted into the orientation protrusion 3 that matches the shape and size of the orientation protrusion 3. Groove 4, the eccentric pipe sleeve 2 is inserted into the screw rod of the eccentric head bolt 1 and after entering the polished rod, its gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com