Wort kettle automatic cycle device comprising conical spiral coil and conical cover

An automatic circulation, conical technology, applied in the direction of beer brewing, wort preparation, biochemical equipment and methods, etc., can solve the problems of uneven mixing, low boiling intensity, large space occupation, etc., to achieve uniform boiling cycle, The effect of high boiling strength and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

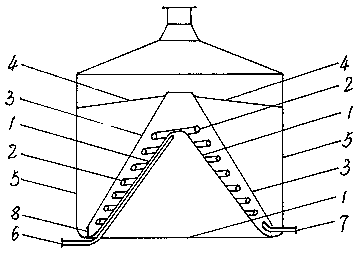

[0010] The invention is attached figure 1 As shown, the device is composed of a conical pot bottom 1, a conical spiral coil 2, a conical cover 3, and an umbrella-shaped liquid leakage tray 4, and the bottom of the cylindrical wort boiling pot 5 is set as a conical pot bottom 1 , Along the conical helical coil 2 on the conical pot bottom 1, the conical cover 3 is covered on the conical helical coil 2, and the umbrella-shaped liquid leakage disc 4 is covered on the conical cover 3. In order to prevent the condensed water from clogging the conical helical coil 2 and ensure the efficient operation of the device, the conical helical coil 2 is set so that one end enters the steam and the other end discharges the condensed water. Extend to the top of the conical pot bottom 1 and enter the pot 5. On the conical pot bottom 1, coil the pipe from top to bottom along the conical spiral, turn the disc to an end 7 of draining condensed water. In order to make the wort circulate well during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com