Process of catalytic deoxidation of oxygen-containing coal bed methane and comprehensive utilization of reaction heat

A technology for catalytic deoxidation and coalbed methane, which is applied in the field of gas deoxidation technology and heat utilization, and can solve the problems of less than 10% utilization rate, waste of resources, waste of heat energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

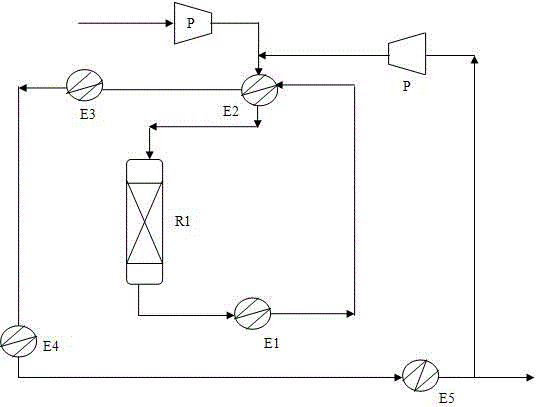

[0055] The invention relates to an oxygen-containing coal bed gas catalytic deoxidation process and comprehensive utilization of reaction heat. In a deoxygenation reactor, methane and oxygen in a raw material mixed gas are reacted in a catalytic reactor containing a catalyst to achieve the purpose of deoxidation. The reactor is a single adiabatic reactor, and the mixed gas enters from the top of the reactor. The temperature, flow rate and oxygen content of the gas during operation are shown in Table 1 below. System pressure 1.1MPa (absolute pressure). The circulation ratio is 0, and the catalyst dosage is 2.5m 3 . The catalyst is a palladium catalyst (CAN-561 produced by Southwest Chemical Research and Design Institute). see process figure 1 .

[0056] The deoxygenated gas exiting the reactor enters the feed gas preheater (E2) to preheat the mixed gas entering the reactor. After the deoxygenation passes through the raw material gas preheater (E2), it enters the deoxygena...

Embodiment 2

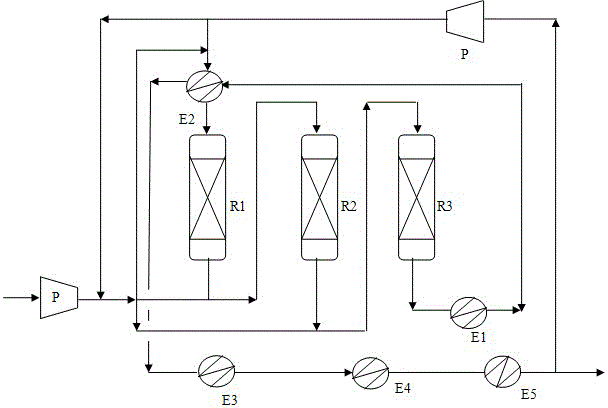

[0062] The invention relates to an oxygen-containing coal bed gas catalytic deoxidation process and comprehensive utilization of reaction heat. In a deoxygenation reactor, methane and oxygen in a raw material mixed gas are reacted in a catalytic reactor containing a catalyst to achieve the purpose of deoxidation. The reactor is a single adiabatic reactor, and the mixed gas enters from the top of the reactor. The temperature, flow rate and oxygen content of the gas during the operation are shown in Table 3 below. System pressure 0.8MPa (absolute pressure). Circulation ratio is 0, catalyst dosage is 2m 3 . The catalyst is the sulfur-resistant deoxidation catalyst disclosed in the Chinese invention patent (ZL200810045665.9), which consists of 30% active components, 30% active auxiliary agents and 40% carriers, that is, the active components are composed of 30% cobalt chloride, The active auxiliary agent is composed of 5% manganese chloride equivalent to manganese dioxide and 2...

Embodiment 3

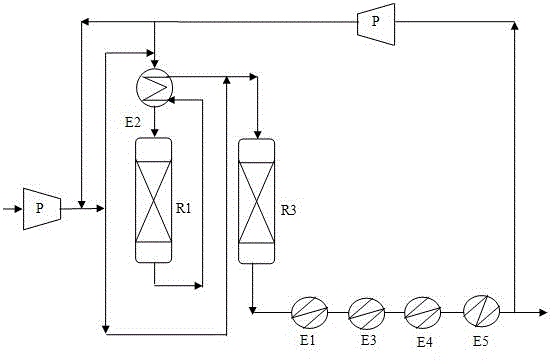

[0069] The invention relates to an oxygen-containing coal bed gas catalytic deoxidation process and comprehensive utilization of reaction heat. In a deoxygenation reactor, methane and oxygen in a raw material mixed gas are reacted in a catalytic reactor containing a catalyst to achieve the purpose of deoxidation. The reactor is a single adiabatic reactor, and the mixed gas enters from the top of the reactor. The temperature, flow rate and oxygen content of the gas during operation are shown in Table 5 below. System pressure 0.4MPa (absolute pressure). Circulation ratio is 0, catalyst dosage is 4m 3 . The catalyst is the ring-shaped manganese-based sulfur-resistant deoxidation catalyst disclosed in the Chinese invention patent (ZL200710049962.6), which is composed of 20% active components, 50% support carriers and 30% binders; the active component is manganese oxalate, the support carrier It is an X-type molecular sieve, the binder is attapulgite, and 10% carboxymethyl cellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com