Reverse osmosis concentrated wastewater treatment method

A technology for reverse osmosis concentration and wastewater treatment, which is applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc. It can solve the problems of high treatment cost and unsatisfactory treatment effect, and reduce the COD value. , the treatment effect is remarkable, the effect of developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

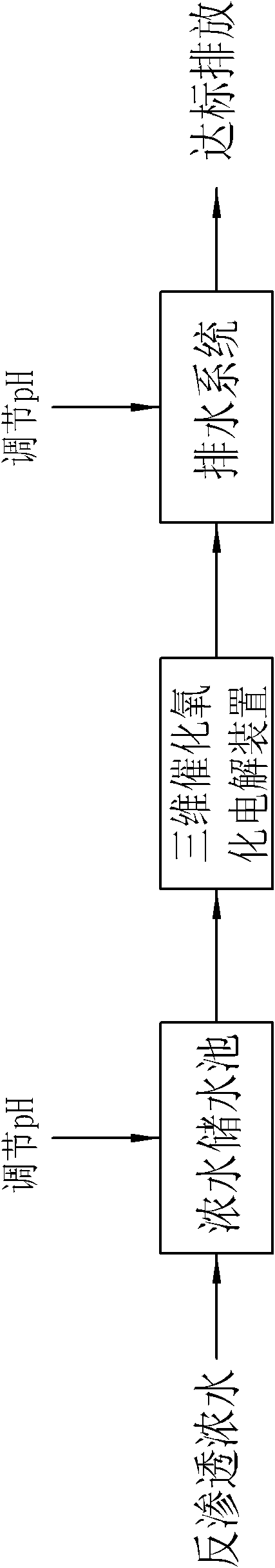

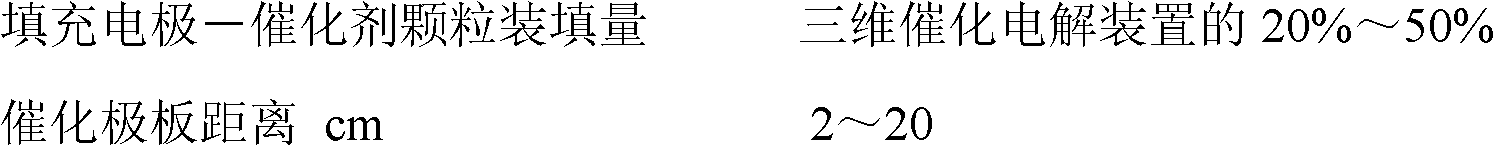

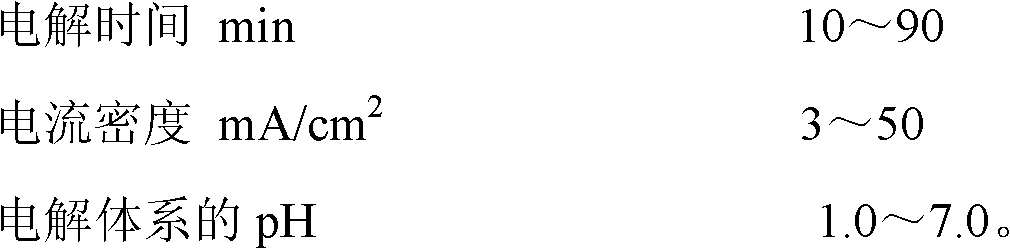

[0048] Concentrated water (COD 365mg / L, pH 7.9) from a reverse osmosis unit enters figure 1 In the process flow shown, the main process parameters of each processing unit are:

[0049] The reverse osmosis concentrated water is added acid in the concentrated water storage tank to adjust the pH value to 2.2, and then enters the catalytic oxidation electrolysis device. The treatment capacity of the electrolysis device is 10L / h, and the high-activity catalyst filled particles added account for about 45% of the volume of the electrolysis device. , both the cathode and the anode use stainless steel mesh as the working electrode, keep the distance between the plates at 10cm, and the electrolysis time is 60min. When the plate voltage is 5V and the current density is 6mA / cm 2 1. When the current intensity is 40mA, the final effluent COD is 55mg / L, the pH value is 2.0, and the COD removal rate reaches 85%. NaOH is added to the catalytic electrolysis water to adjust the pH value to 6.8,...

Embodiment 2

[0051] Concentrated water (COD 134mg / L, pH 6.5) from a reverse osmosis unit enters figure 1 In the process flow shown, the main process parameters of each processing unit are:

[0052] The reverse osmosis concentrated water is added acid in the concentrated water storage tank to adjust the pH value to 4.0 and then enters the catalytic oxidation electrolysis device. The treatment capacity of the electrolysis device is 12L / h, and the high-activity catalyst filled particles added account for about 50% of the volume of the electrolysis device. %, the cathode is made of stainless steel plate, the anode is made of graphite electrode as the working electrode, the distance between the plates is kept at 6cm, the electrolysis time is 30min, when the plate voltage is 6V and the current density is 3mA / cm 2 , When the current intensity is 1A, the final effluent COD is 40mg / L, the pH value is 2.85, and the COD removal rate reaches 70%. NaOH is added to the catalytic electrolysis water to a...

Embodiment 3

[0054] Concentrated water (COD 95mg / L, pH 8.2) from a reverse osmosis unit enters figure 1 In the process flow shown, the main process parameters of each processing unit are:

[0055] The reverse osmosis concentrated water is added acid in the concentrated water storage tank to adjust the pH value to 3.2, and then enters the catalytic oxidation electrolysis device. The treatment capacity of the electrolysis device is 8L / h, and the high-activity catalyst filled particles added account for about 30% of the volume of the electrolysis device. %, both the cathode and the anode use stainless steel plates as the working electrodes, keep the distance between the plates at 8cm, and the electrolysis time is 40min. When the plate voltage is 6V and the current density is 1.6mA / cm 2 , When the current intensity is 1.25A, the final effluent COD is 35mg / L, the pH value is 3.07, and the COD removal rate reaches 63%. NaOH is added to the catalytic electrolysis water to adjust the pH value to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com