Method for treating sodium sulfide waste water

A technology for soda sulfide and waste water, which is applied in the direction of oxidized water/sewage treatment, thiosulfate/dithionite/polythionite, etc., and can solve the problems of ineffective treatment, high cost, time-consuming and laborious, etc. , to achieve the effects of reducing production and operating costs, improving safety, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

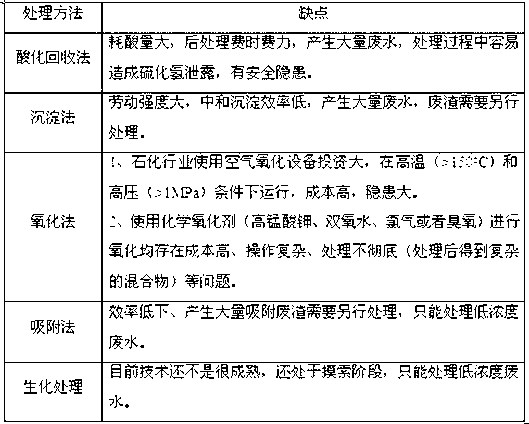

Problems solved by technology

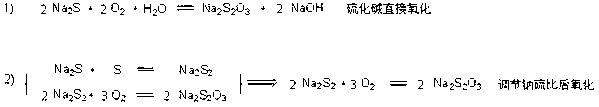

Method used

Image

Examples

Embodiment 1

[0021] Add 3500kg (39%) of high-concentration alkali sulfide wastewater into the 5000L reactor, 589kg (95%) of industrial waste sulfur, and 1.7kg of ferrous ammonium sulfate, start stirring, raise the temperature to 50°C, start to introduce air, and control the reaction temperature at 50 o C, the reaction pressure is 0.3MPa, and the reaction is completed after 12 hours. After the reaction is completed, it is heated and filtered. After the filtered solid catalyst is collected, it is put back into the reactor for recycling. Concentrate under vacuum at -0.09MPa until the volume is reduced by 1 / 3, and then crystallize after cooling, the temperature of cooling crystallization is 16-24 degrees; finally, after filtering and drying, 2100kg of sodium thiosulfate pentahydrate is obtained, with a content of 98.89%.

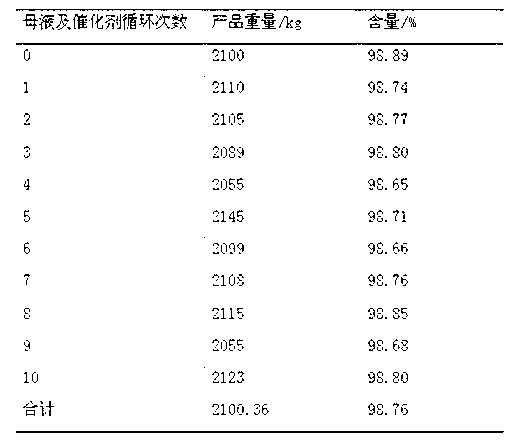

[0022] Filter the obtained catalyst residue and the mother liquor to be reused in the following 10 reaction cycles without any treatment, the average available product is 21...

Embodiment 2

[0025] Add 3600 (36%) kg of high-concentration alkali sulfide wastewater, 560 kg (95%) of industrial waste sulfur, and 1.8 kg of composite catalyst (aluminum oxide: manganese sulfate = 1:2) into the 5000L reactor, start stirring, and heat up to 70°C, start to feed air, and control the reaction temperature at 70°C o C. The reaction pressure is 0.1MPa, and the reaction is completed after 6 hours. After the reaction is completed, it is heated and filtered. After the filtered solid catalyst is collected, it is put back into the reactor for recycling. Concentrate under vacuum at -0.09MPa until the volume is reduced by 1 / 3, and then crystallize on cooling, the temperature of cooling crystallization is 10-15 degrees; after filtering and drying, 2122kg of sodium thiosulfate pentahydrate is obtained, with a content of 98.86%.

Embodiment 3

[0027] Add 3500kg (35%) of high-concentration sodium sulfide wastewater into the 5000L reactor, 529kg (95%) of industrial waste sulfur, and 1.6kg of fly ash. o C, the reaction pressure is 0.4MPa, the reaction is completed after 10 hours, after the reaction is completed, it is heated and filtered, and the filtered solid catalyst is collected and then put into the reactor for recycling. Concentrate under vacuum conditions at -0.09MPa until the volume is reduced by 1 / 3, and then crystallize after cooling. The temperature of cooling crystallization is 30-40 degrees. Finally, after filtering and drying, 2087kg of sodium thiosulfate pentahydrate is obtained, with a content of 98.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com